Costustoot-ambergris spice and preparation method thereof

A technology of ambergris and woody aroma, which is applied in the direction of essential oil/fragrance, ether preparation, ester reaction to prepare ether, etc. It can solve the problems of high production cost of methyl cedryl ether, insufficient supply of cedarin, and limited cedarwood oil resources. Achieve effects suitable for large-scale production, soft aroma, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation cost of the woody-ambergris fragrance provided by the invention is relatively low. In addition, the woody-ambergris fragrance provided by the invention has better aroma performance.

[0027] The invention provides a preparation method of woody-ambergris spice, comprising:

[0028] Carry out the first reaction with epoxy cedarane and basic sodium salt, obtain intermediate product;

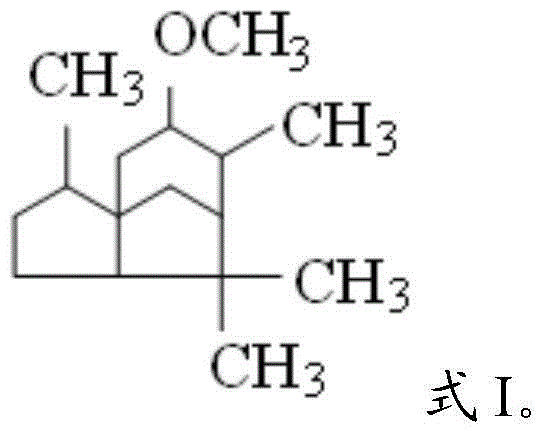

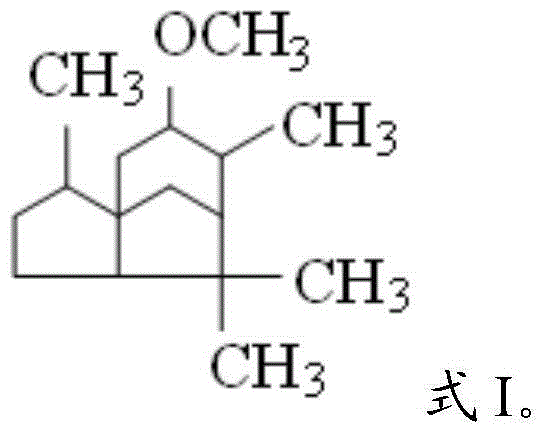

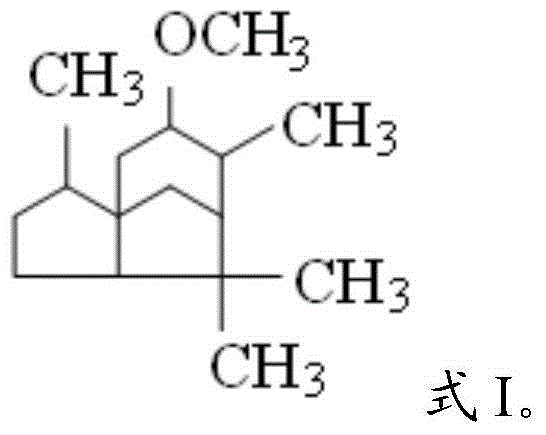

[0029] The intermediate product and the methylating reagent are carried out to the second reaction to obtain the woody-ambergris fragrance with the structure shown in formula I:

[0030]

[0031] In the present invention, the first reaction is carried out with the epoxy cedarane and the basic sodium salt to obtain the intermediate product. In an embodiment of the present invention, the temperature of the first reaction is greater than or equal to 50°C; in other embodiments, the temperature of the first reaction may be 50°C to 100°C; in another embodiment, the The tempera...

Embodiment 1

[0056] In the reaction flask with agitator, reflux condenser and dropping funnel, add 400mL of xylene and 27g (1.1mol) of sodium hydride, start the agitator, and heat the reaction flask to 100°C; 220g (1.0mol) of epoxy cedrene was added dropwise in the reaction flask, heated to reflux under stirring conditions, and carried out the first reaction of 3 hours to obtain an intermediate product; 140g (1.1mol) of dimethyl sulfate was added to Add it dropwise to the intermediate product within 1 hour, heat to reflux under stirring condition, and carry out the second reaction for 5 hours.

[0057] After the second reaction is completed, the obtained reaction product is cooled to 35° C., and the cooled reaction product is extracted with 200 mL of a 10% aqueous sodium hydroxide solution, and left to separate into a water layer and an oil layer; The water layer was removed by filtration; the oil layer was washed with 100 mL of water, and the solvent xylene in the washed product was recov...

Embodiment 2

[0067] In the reaction flask with agitator, reflux condenser and dropping funnel, add 400mL of toluene and 30g (1.25mol) of sodium hydride, start the agitator, and heat the reaction flask to 70°C; within 0.5 hours The solution prepared by 220g (1.0mol) of epoxy cedrene and 200mL of toluene was added dropwise in the reaction flask, heated to reflux under stirring conditions, and carried out the first reaction for 5 hours to obtain the intermediate product; adjust the reaction flask temperature to 50 °C, 100 g of methyl chloride was introduced into the intermediate product within 1 hour, and then the second reaction was carried out at 50 °C for 4 hours.

[0068] After the second reaction is completed, the obtained reaction product is cooled to 30° C., and the cooled reaction product is extracted with 200 mL of a 10% aqueous sodium hydroxide solution, and left to separate into a water layer and an oil layer; The water layer was removed by filtration; the oil layer was washed with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com