Method for preparing ester compound from subcritical/supercritical ethanol liquified straw cellulose

A technology of ester compounds and cellulose, which is applied in the field of sub-/supercritical ethanol liquefaction of straw cellulose to prepare ester compounds, can solve the problems of lack of systematic research, slow progress, late straw biomass liquefaction technology, etc., and achieve practical promotion Strong resistance, high conversion efficiency, and low performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

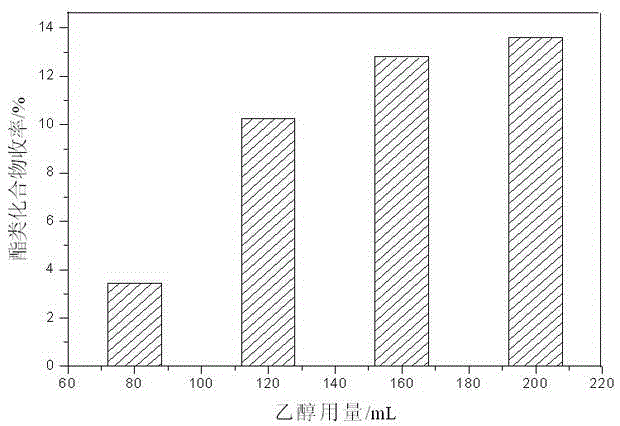

[0029] Embodiment 1 The influence of the amount of ethanol on the yield of ester compounds

[0030] Crush corn stalks to a particle size of 50-60 meshes. After drying, take 15 g of straw cellulose powder, mix them with 0, 80, 120, 160, and 200 mL of ethanol, and add them to a 1-L container with a magnetic stirrer. In a batch-type autoclave, heat up to 300 °C after sealing, and keep the reaction at this temperature for 60 min. Cool to room temperature and collect the product. Wash the inner wall of the reactor with absolute ethanol to obtain a solid-liquid product, place it at room temperature until the ethanol evaporates to dryness, then add distilled water to extract, filter the water-soluble organic matter with a vacuum pump, and use a rotary evaporator to evaporate the water from the filtrate, leaving The substance is water-soluble organic matter, namely light oil; when distilled water is extracted, the water-insoluble solid matter is extracted with absolute ethanol, filte...

Embodiment 2

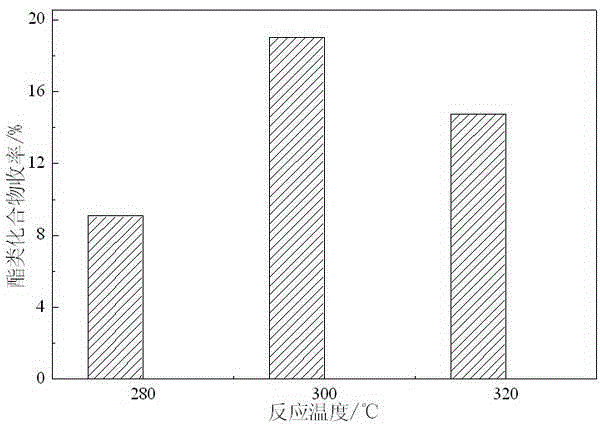

[0035] Embodiment 2 The influence of temperature of reaction on ester compound yield

[0036] Crush the forage raw material to a particle size of 50-60 mesh, take 15 g of forage cellulose powder after drying, mix it with 200 mL of ethanol, and add it to a batch-type autoclave with a volume of 1 L with a magnetic stirrer, and seal it. The temperature was raised to 280, 300, and 320 °C respectively, and the reaction was maintained for 90 min. Cool to room temperature and collect the product. The product collection method is the same as in Example 1. The product yield is calculated based on the mass of the obtained product divided by the mass of the raw material after removing the ash.

[0037]GC-MS was used to qualitatively analyze the bio-oil produced by the liquefaction of forage cellulose under the conditions of 200 mL of ethanol, 90 min of reaction time, and 280 °C, 300 °C, and 320 °C respectively, and the esters were obtained by calculation. The yield of compound is show...

Embodiment 3

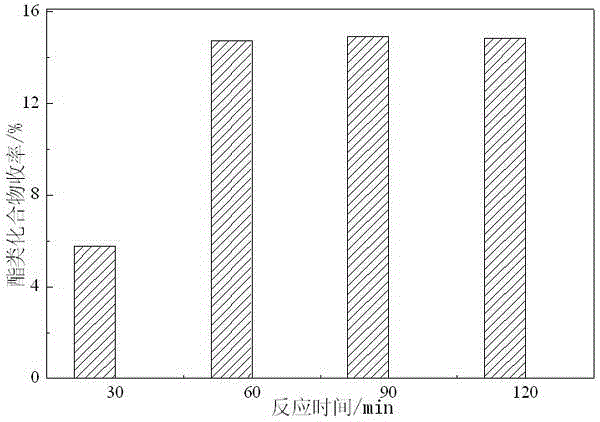

[0041] Embodiment 3 reaction time is to the influence of ester compound yield

[0042] Crush the bagasse raw material to a particle size of 50-60 mesh, take 15 g of bagasse cellulose powder after drying, mix it with 120 mL of ethanol, add it to a batch-type autoclave with a volume of 1 L and a magnetic stirrer, heat up after sealing To 300 ℃, and keep the reaction at the set temperature for 30, 60, 90, 120min respectively. Cool to room temperature and collect the product. The product collection method is the same as in Example 1. The product yield is calculated based on the mass of the obtained product divided by the mass of the raw material after removing the ash.

[0043] GC-MS was used to qualitatively analyze the bio-oil produced by the liquefaction of bagasse cellulose under the conditions of ethanol dosage of 120 mL, reaction temperature of 300°C, and reaction time of 30 min, 60 min, 90 min and 120 min respectively, and the ester compounds were obtained by calculation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com