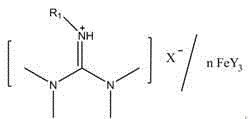

Novel guanidine magnetic ionic liquid and application thereof in removal of sulfur-containing organic matters in nonpolar solution

A magnetic ionic liquid, non-polar technology, used in the preparation of organic compounds, organic chemistry, extraction and purification/separation, etc., can solve the problems of oil loss, harsh operating conditions, changing oil composition, etc., and achieve recycling and reuse. Reduced, chemically stable, fast mass transfer balance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

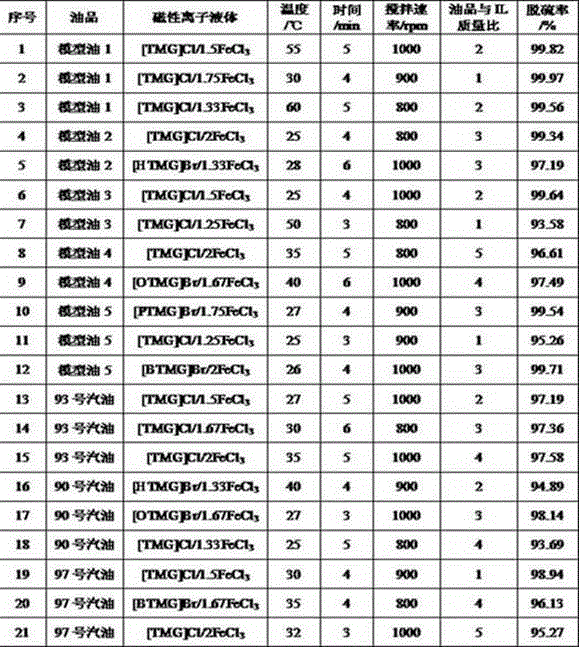

Examples

Embodiment 1

[0032] Example 1 ( Ionic liquid is [TMG][FeCl 4 ] Synthetic method 1):

[0033]

[0034] Weigh 11.5g of N,N-tetramethylguanidine (0.1mol) into a 50ml round bottom flask, add 15ml of acetonitrile as a solvent, place in ice bath, control the temperature at 0°C, and stir. Measure 0.12 mol of concentrated hydrochloric acid, slowly drop it into the round bottom flask within 30 min, continue to stir for 2 h, and rotary evaporate under reduced pressure until the solvent is completely removed to obtain a white solid, namely the intermediate [TMG]Cl.

[0035] Accurately weigh 0.1mol anhydrous FeCl 3 , directly added to the above round-bottomed flask, a dark brown liquid was rapidly formed, stirred at room temperature for 4 hours, added a small amount of methanol and rotary evaporated under reduced pressure for 3 hours, and finally obtained a brownish-yellow uniform liquid, which was the product [TMG][FeCl 4 ].

Embodiment 2

[0036] Example 2 ( Ionic liquid is [TMG][FeCl 4 ] Synthetic method 2):

[0037] Weigh 17.25g of N,N-tetramethylguanidine (0.15mol) into a 50ml round bottom flask, add 30ml of methanol as a solvent, and stir at room temperature. Measure 0.18mol of concentrated hydrochloric acid, slowly add it dropwise into a round bottom flask within 70min, continue to stir for 4h, and rotate under reduced pressure for 3h, then add 10ml of methanol and rotate under reduced pressure until the solvent is completely removed, and after vacuum drying, a white solid is obtained, namely Intermediate [TMG]Cl.

[0038] Accurately weigh 0.5mol anhydrous FeCl 3 , directly added to the above-mentioned round bottom flask, a dark brown liquid was rapidly formed, stirred at room temperature for 5 hours, added 5ml of methanol and rotary steamed under reduced pressure for 3 hours, and finally obtained a brownish-yellow uniform liquid, which was the product [TMG][FeCl 4 ].

Embodiment 3

[0039] Example 3 ( Ionic liquid [TMG]Cl / 1.25FeCl 3 synthesis method):

[0040]

[0041] Weigh 13.8g of N,N-tetramethylguanidine (0.12mol) into a 50ml round bottom flask, add 20ml of ethanol as a solvent, place in ice bath, control the temperature below 5°C, and stir. Measure 0.14mol of concentrated hydrochloric acid, slowly drop it into the round bottom flask within 30min, continue to stir for 2h, and rotary evaporate under reduced pressure until the solvent is completely removed to obtain a white solid, the intermediate [TMG]Cl.

[0042] Accurately weigh 0.15mol anhydrous FeCl 3 , directly added to the above round-bottomed flask, a dark brown liquid was rapidly formed, stirred at room temperature for 5 hours, ultrasonically oscillated for 0.5 hours, added a small amount of methanol and rotated under reduced pressure for 2 hours, and finally obtained a dark brown uniform liquid with a color slightly darker than that of [TMG][FeCl 4 ], which is the product [TMG]Cl / 1.25FeCl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com