In-situ-polymerized halogen-free flame-retardant nylon 6/attapulgite nano composite material and preparation method thereof

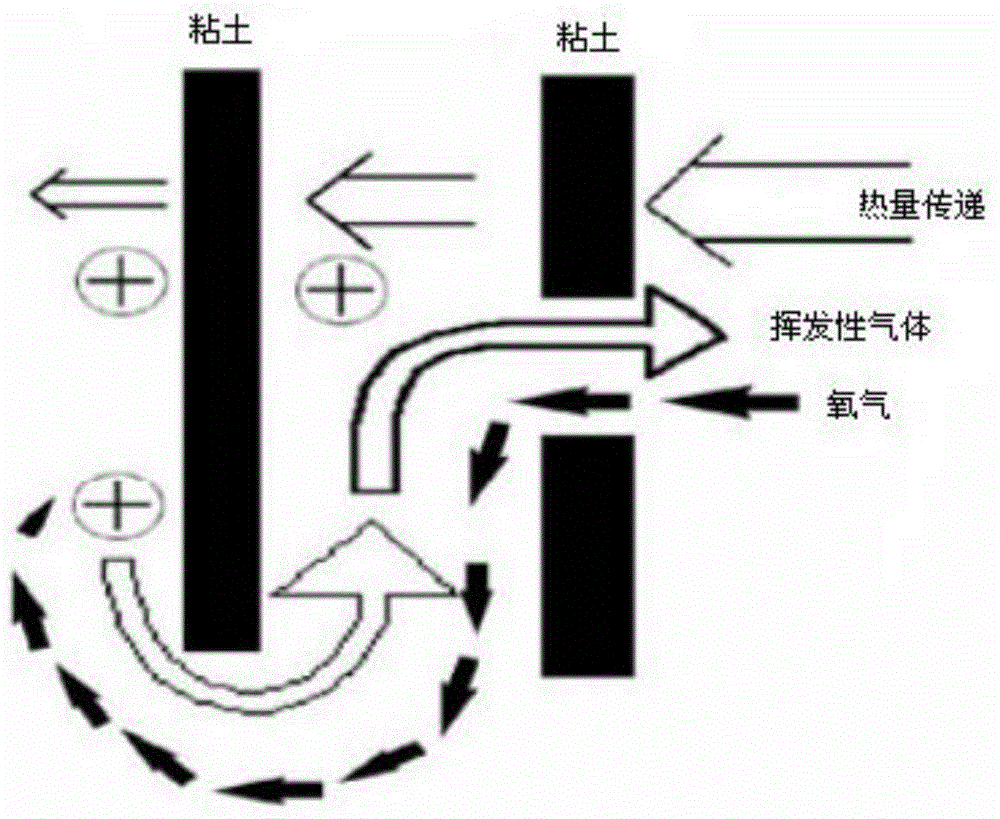

A nanocomposite material and in-situ polymerization technology, which is applied in the field of in-situ polymerization of halogen-free flame retardant nylon 6/attapulgite nanocomposite materials and its preparation, can solve the problem of large amount of flame retardant, poor flame retardant effect, and the Large smoke volume and other problems, to achieve the effect of long flame retardant life, good flame retardant and smoke suppression, and reduce internal stress

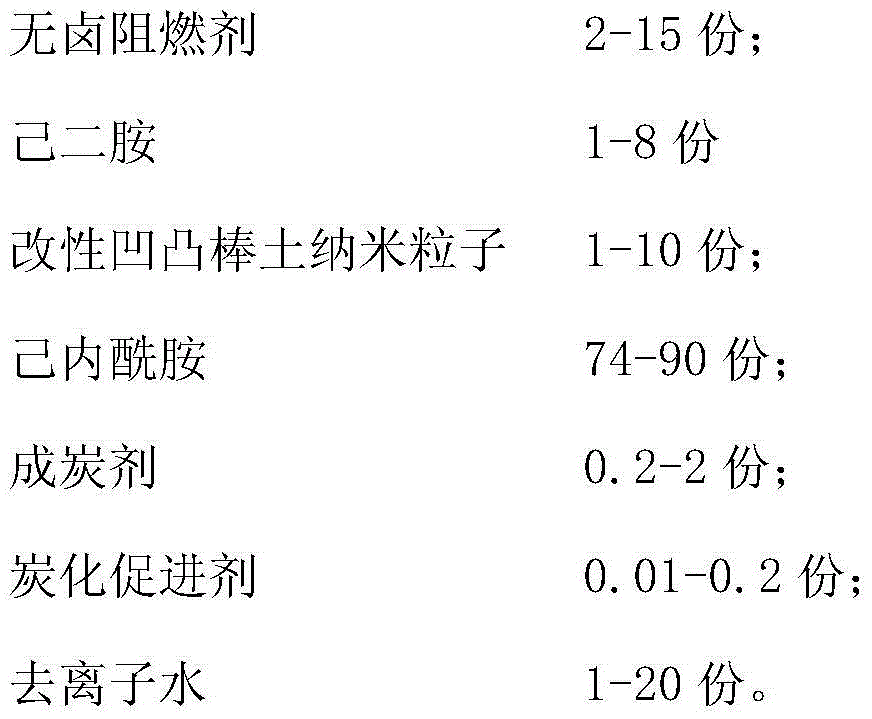

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0032] Step 1, preparation of modified attapulgite nanoparticles

[0033] 1 part by weight of deionized water and 5 parts by weight of nano-attapulgite are uniformly dispersed in 100 parts by weight of toluene, 4 parts by weight of aminopropyltrimethoxysilane are added, and ultrasonically dispersed for 1 hour to form a mixture; React at 50°C for 5 hours, then wash, dry and sieve to obtain modified attapulgite. The reaction equation is:

[0034]

[0035] Step 2, preparation of flame retardant salt

[0036] The preparation method of the halogen-free flame retardant is as follows: 10 parts by weight of 2-carboxyethylphenylphosphinic acid and 5 parts by weight of hexamethylenediamine are dissolved in N,N-dimethylformamide, and the water temperature is kept in a constant temperature water bath. React at 55°C for 3-5h, then cool, filter, and wash with absolute ethanol. The reaction equation is:

[0037]

[0038] Step 3, preparation of flame retardant composite material

...

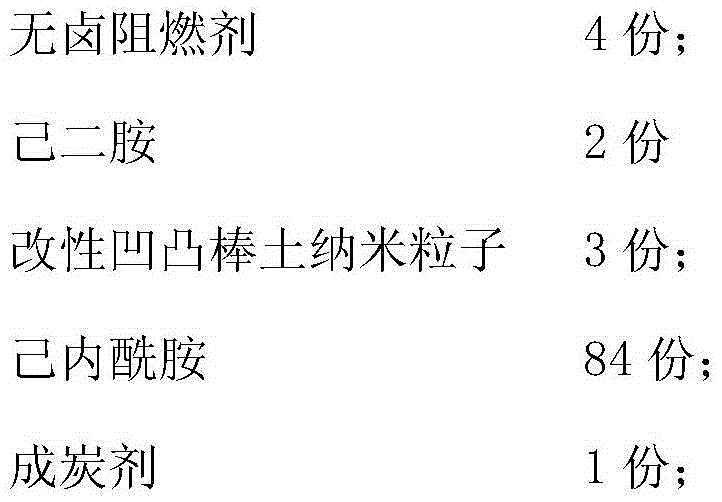

Embodiment 2)

[0042] Step 1, preparation of modified attapulgite nanoparticles

[0043] 1 part by weight of deionized water and 5 parts by weight of nano-attapulgite are uniformly dispersed in 100 parts by weight of toluene, 4 parts by weight of aminopropyltriethoxysilane are added, and ultrasonically dispersed for 1 hour to form a mixture; the mixture is mechanically stirred React at a temperature of 50°C for 5 hours, then wash, dry and sieve to obtain modified attapulgite.

[0044] Step 2, preparation of flame retardant salt

[0045] The preparation method of the halogen-free flame retardant is as follows: 4 parts by weight of bis(p-carboxyphenyl)phenylphosphine oxide and 2 parts by weight of hexamethylenediamine are dissolved in N,N-dimethylformamide, and the constant temperature water bath Keep the water temperature at 55°C and react for 3-5h, then cool, filter, and wash with absolute ethanol.

[0046] Step 3, preparation of flame retardant composite material

[0047] 84 parts by wei...

Embodiment 3)

[0049] Step 1, preparation of modified attapulgite nanoparticles

[0050] 1 part by weight of deionized water and 5 parts by weight of nano-attapulgite are uniformly dispersed in 100 parts by weight of toluene, 4 parts by weight of anilinomethyltriethoxysilane are added, and ultrasonically dispersed for 1 h to form a mixture; the mixture is mechanically stirred React at a temperature of 50° C. for 5 hours, then wash, dry and sieve to obtain modified attapulgite.

[0051] Step 2, preparation of flame retardant salt

[0052] The preparation method of the halogen-free flame retardant is as follows: 15 parts by weight of 2-carboxyethylphenylphosphinic acid and 5 parts by weight of hexamethylenediamine are dissolved in N,N-dimethylformamide, and the water temperature is kept in a constant temperature water bath. React at 55°C for 3-5h, then cool, filter, and wash with absolute ethanol.

[0053] Step 3, preparation of flame retardant composite material

[0054] Add 90 parts by we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com