Modified cyanate ester resin and preparation method thereof

A technology of cyanate resin and cyanate ester, applied in the field of modified cyanate ester resin and its preparation, can solve problems such as the inability to achieve multi-functionality, and achieve the goal of inhibiting the diffusion of heat, improving the reactivity, and reducing the dielectric constant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Preparation of graphene oxide-manganese-based metal-organic framework hybrids

[0032] Add 1.1g of potassium hydroxide, 0.68g of imidazole, 2.64g of 4,4’-dicarboxydiphenyl ether and 0.18g of graphene oxide into 70mL of deionized water, and ultrasonically disperse at 60°C for 30min to obtain solution A.

[0033] Solution B was obtained by dissolving 2.45 g of manganese acetate tetrahydrate in 10 mL of deionized water.

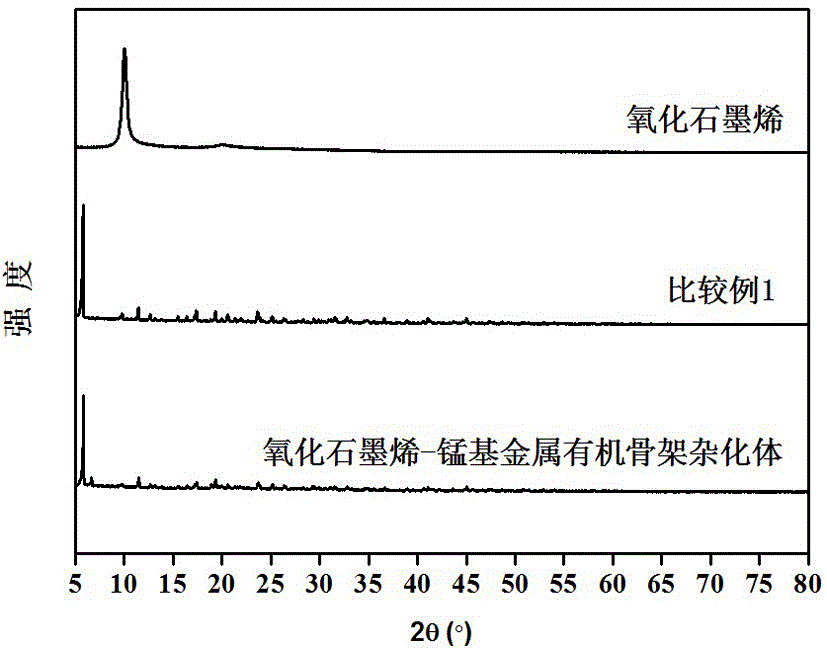

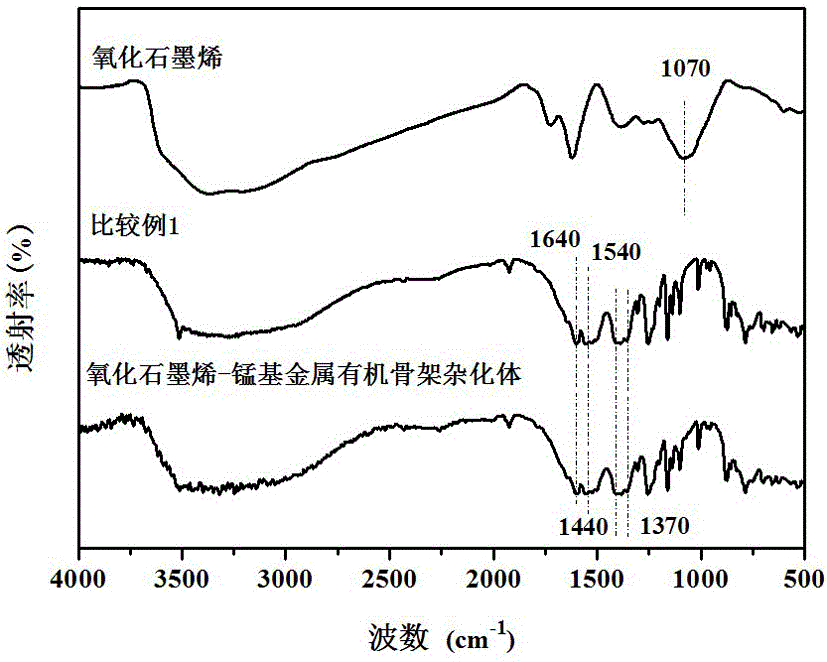

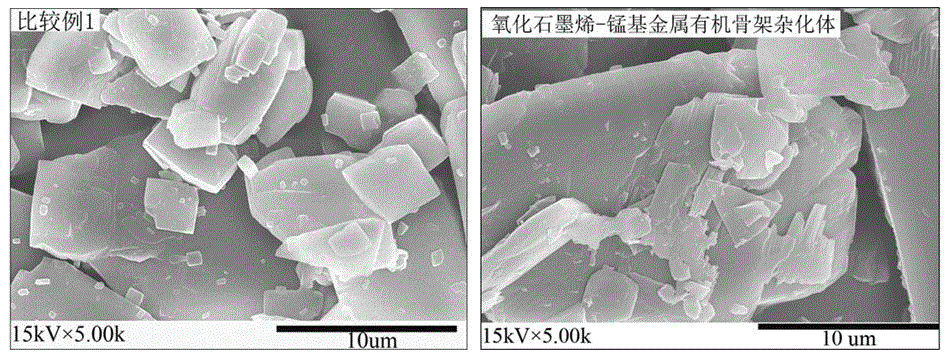

[0034] Add solution A dropwise to solution B, stir and react at 75°C for 24 hours, filter with suction, wash, and dry to obtain a catalyst graphene oxide-manganese-based metal-organic framework hybrid, in which graphene oxide and manganese-based metal The mass fractions of organic frameworks are 5wt% and 95wt%, respectively. The graphene oxide-manganese-based metal-organic framework hybrid catalyst X-ray diffraction pattern, infrared spectrogram, and scanning electron microscope image magnified 5,000 times refer to the attached figure 1 , 2 and 3. ...

Embodiment 2

[0045] Preparation of graphene oxide-manganese-based metal-organic framework hybrid / cyanate resin prepolymer

[0046] Add 2g of graphene oxide-manganese-based metal-organic framework hybrid material and 48g of bisphenol A cyanate prepared in step 1 of Example 1 into a beaker, stir at 85°C and ultrasonically for 30min, and then at 130°C Stir for 15 minutes to obtain a uniform mixture, which is 4wt% graphene oxide-manganese-based metal organic framework / cyanate resin prepolymer. Its differential scanning calorimetry (DSC) curve see Figure 4 and 5

Embodiment 3

[0048] Preparation of graphene oxide-manganese-based metal-organic framework hybrid / cyanate resin prepolymer:

[0049] Add 3g of graphene oxide-manganese-based metal-organic framework hybrid catalyst and 47g of bisphenol A type cyanate prepared in step 1 of Example 1 into a beaker, stir at 85°C and ultrasonically for 30min, then at 130°C Stir for 15 minutes to obtain a homogeneous mixture, which is a 6wt% graphene oxide-manganese-based metal-organic framework / cyanate resin prepolymer. For its differential scanning calorimetry curve, see Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com