Method for preparing micro-algal oil by microalgae hydro-thermal liquefaction

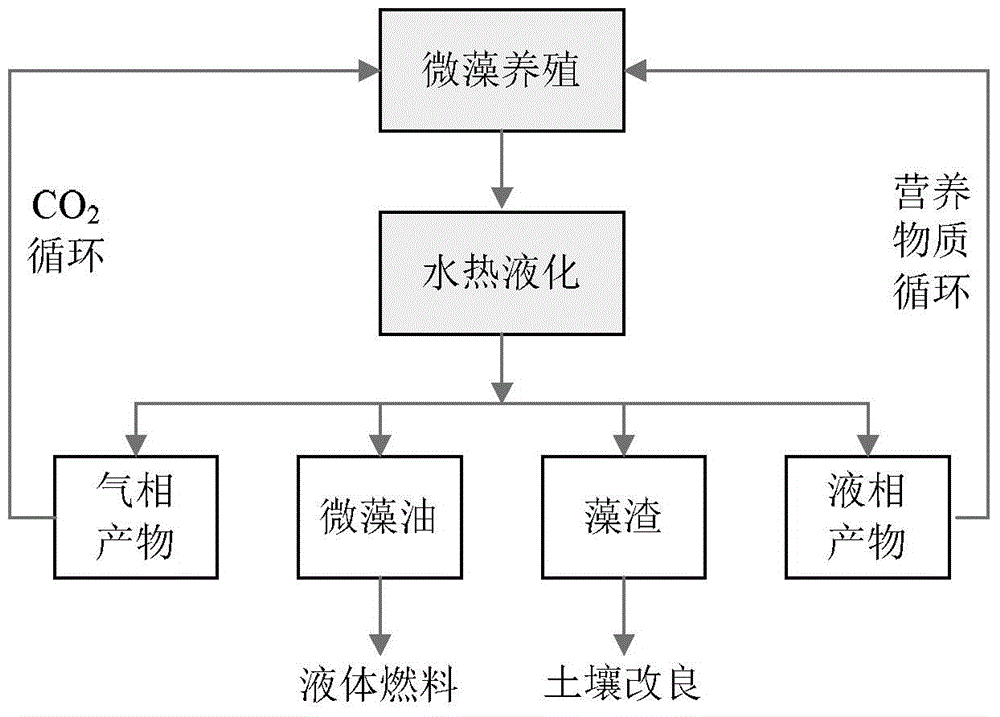

A technology of hydrothermal liquefaction and microalgae oil, which is applied in the preparation of liquid hydrocarbon mixtures, the petroleum industry, and the treatment of hydrocarbon oils. It can solve the problems of high equipment requirements, achieve small land occupation, fast growth and reproduction, and high calorific value. The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Using microalgae as raw materials, take 20g of microalgae and 150ml of distilled water and put them into a 300ml high-pressure reactor, and stir to prepare microalgae slurry. The reactor was sealed, with N 2 Drain the air in the kettle, turn on the heating switch, set the stirring speed to 200r / min, start to heat up to 300°C at a rate of about 4°C / min, keep it for 30min, turn off the heating switch immediately, cool to room temperature, collect the generated gas, and turn on Take out the reaction mixture from the kettle, and use CH 2 Cl 2 Clean the inner wall of the reaction kettle and the stirrer, and extract the mixture. Separate the extract and filter the CH with a Buchner funnel 2 Cl 2 phase, and then recover CH by vacuum distillation 2 Cl 2 , to obtain microalgae oil.

[0023] The yield of microalgae oil was 23.00%, and the calorific value was 35.81KJ / g. The water-soluble phase product can be recycled and used for microalgae cultivation after certain treatm...

Embodiment 2

[0025] Using microalgae as raw material, take 20g of microalgae and 200ml of distilled water into a 300ml autoclave, stir to prepare microalgae slurry. The reactor was sealed, with N 2 Drain the air in the kettle, turn on the heating switch, set the stirring speed at 200r / min, start to heat up to 320°C at a rate of about 4°C / min, keep it for 30min, turn off the heating switch immediately, cool to room temperature, collect the generated gas, and turn on Take out the reaction mixture from the kettle, and use CH 2 Cl 2 Clean the inner wall of the reaction kettle and the stirrer, and extract the mixture. Separate the extract and filter the CH with a Buchner funnel 2 Cl 2 phase, and then recover CH by vacuum distillation 2 Cl 2 , to obtain microalgae oil.

[0026] The yield of microalgae oil is 30.62%, and the calorific value is 32.34KJ / g. The water-soluble phase product can be recycled and used for microalgae culture after certain treatment, and the remaining solid-phase a...

Embodiment 3

[0028] Using microalgae as raw material, take 20g of microalgae and 200ml of NaOH solution with a concentration of 5.0%, put them into a 300ml high-pressure reactor, and stir to prepare a microalgae slurry. The reactor was sealed, with N 2 Exhaust the air in the kettle, turn on the heating switch, set the stirring speed at 200r / min, start to heat up to 300℃ at a rate of about 4℃ / min, keep it for 30min, turn off the heating switch immediately, cool to room temperature, collect the generated gas, and open the kettle Take out the reaction mixture, utilize CH 2 Cl 2 Clean the inner wall of the reaction kettle and the stirrer, and extract the mixture. Separate the extract and filter the CH with a Buchner funnel 2 Cl 2 phase, and then recover CH by vacuum distillation 2 Cl 2 , to obtain microalgae oil.

[0029] The yield of microalgae oil is 32.83%, and the calorific value is 30.53KJ / g. The water-soluble phase product can be recycled and used for microalgae culture after cer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com