High-iron cupronickel alloy pipe and short-process production method thereof

A technology of white copper tube and short process, which is applied in the field of high-iron white copper pipe and its short process production, which can solve the problems of poor processing performance and low yield of iron-nickel copper, achieve excellent cold working performance, improve cold working performance, and good internal and external surface quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

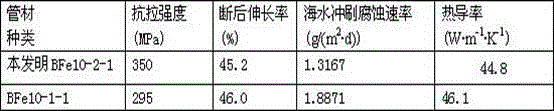

Examples

Embodiment 1

[0022] Embodiment 1: The size is Φ60×3mm BFe10-2-1 white copper alloy straight tube production method

[0023] (1) Electrolytic nickel with a weight percentage of 10.0wt%, pure iron with a weight percentage of 2.0wt%, and 100% by weight

[0024] Add 1.0wt% pure manganese and the rest electrolytic copper into the melting furnace, heat to 1250°C for melting, transfer the molten metal into the holding furnace, and let it stand for 0.5h at the temperature of the holding furnace at 1200°C , At the same time, the inert gas protection is passed through the holding furnace.

[0025] (2) A high-iron white copper tube billet with a diameter of Φ85×10mm was prepared by the horizontal continuous casting process of hot-cold combined casting mold,

[0026] The temperature of the hot type (mold heating section) is 1220°C, the cooling water flow rate of the cold type (water-cooled copper sleeve) is 900L / h, and the pulling speed is 120mm / min.

[0027] (3) The tube blank prepared in step (2) ...

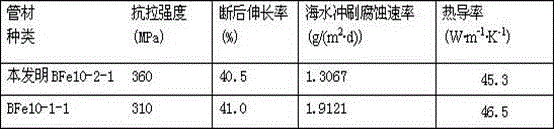

Embodiment 2

[0033] Example 2: The production method of BFe10-2-1 white copper straight tube with a size of Φ40×2mm

[0034] (1) Electrolytic nickel with a weight percentage of 10.0wt%, pure iron with a weight percentage of 1.8wt%, and 100% by weight

[0035] Add pure manganese with a ratio of 1.0wt% and the balance of electrolytic copper into the melting furnace, heat to 1250°C for melting, transfer the molten metal into the holding furnace, and let it stand for 0.5h at the temperature of the holding furnace at 1200°C , At the same time, the inert gas protection is passed through the holding furnace.

[0036] (2) A high-iron white copper tube billet with a diameter of Φ70×8mm was prepared by the horizontal continuous casting process of hot-cold combined mold,

[0037] The temperature of the hot mold (casting mold heating section) is 1200°C, the cooling water flow rate of the cold mold (water-cooled copper sleeve) is 700L / h, and the pulling speed is 150mm / min.

[0038] (3) The tube blank p...

Embodiment 3

[0044] Embodiment 3: The production method of BFe10-2-1 white copper coil with a size of Φ15×1mm

[0045] (1) Electrolytic nickel with a weight percentage of 10.0wt%, pure iron with a weight percentage of 1.8wt%, and 100% by weight

[0046] Pure manganese with a ratio of 1.0wt% and the balance of electrolytic copper are added to the melting furnace, heated to 1250°C for melting, and the molten metal is transferred into the holding furnace, and the standing time is 0.5 under the temperature of the holding furnace at 1200°C. h, while inert gas protection is passed through the holding furnace.

[0047] (2) A hot-cold combined mold horizontal continuous casting process is used to prepare a cupronickel alloy tube billet with a diameter of Φ50×5mm.

[0048] The temperature of the hot mold (mold heating section) is 1200°C, the cooling water flow rate of the cold mold (water-cooled copper sleeve) is 600L / h, and the pulling speed is 150mm / min.

[0049] (3) The tube billet prepared in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com