High-capacity lithium ion battery anode material 0.5Li2MnO3*0.5LiMn1/3Ni1/3Co1/3O2 and preparation method thereof

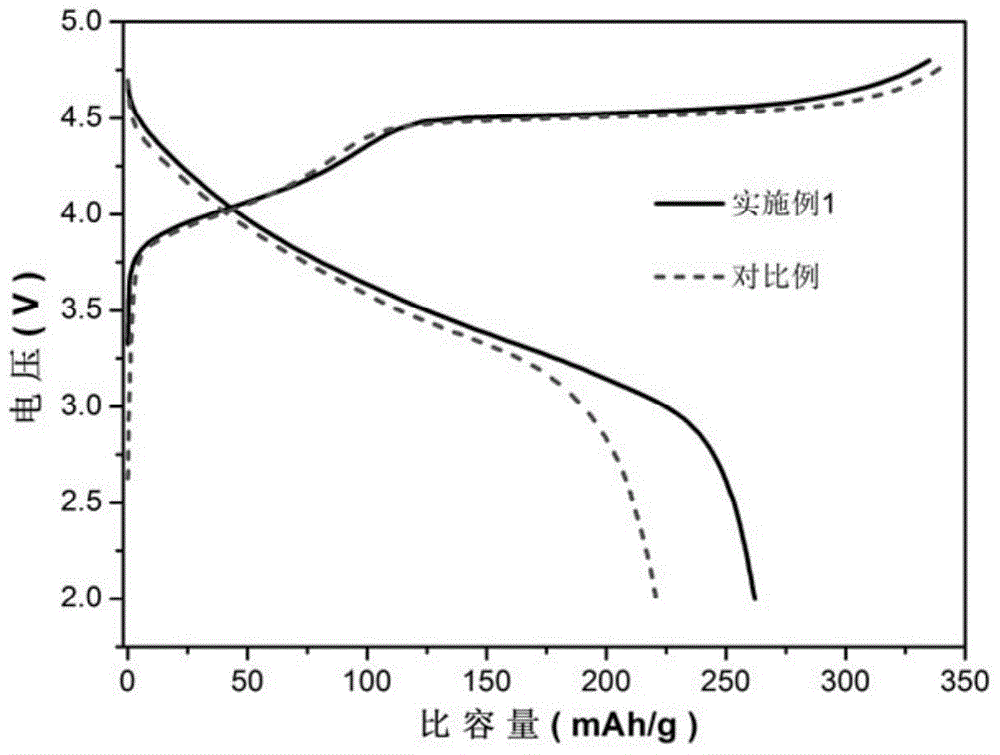

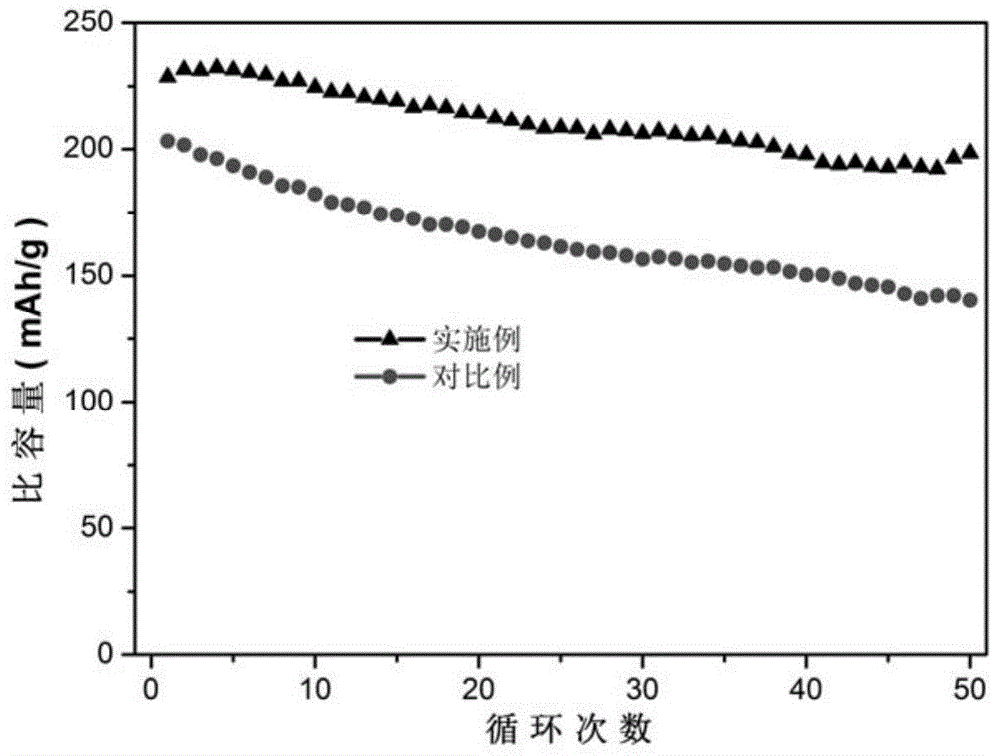

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of large initial capacity loss, voltage drop, and poor rate performance, and achieve simple, fast and convenient reaction process and low capacity loss , the effect of increasing energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

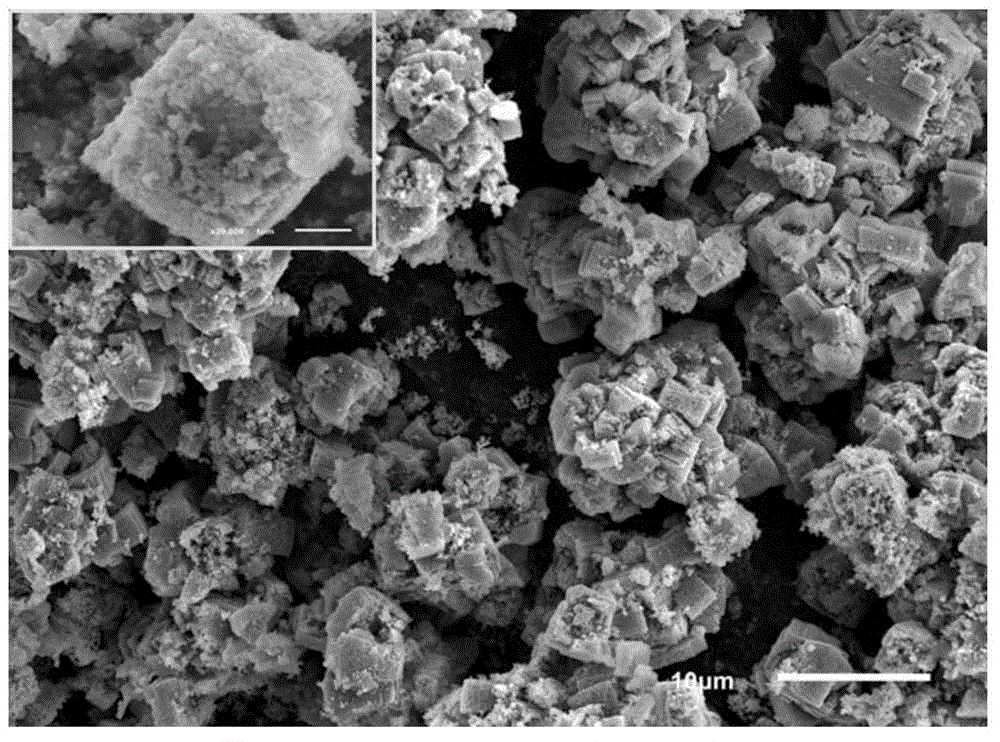

Embodiment 1

[0030] A kind of anode material 0.5Li for high-capacity lithium-ion battery 2 MnO3 0.5LiMn 1 / 3 Ni 1 / 3 co 1 / 3 o 2 The preparation method comprises the following steps:

[0031] (1) Under stirring conditions, add 80mL deionized water to a 250mL high-necked beaker, then add 5.2g lithium acetate dihydrate, 5.2g manganese acetate tetrahydrate, 1.3g nickel acetate tetrahydrate and 1.3g acetic acid tetrahydrate For cobalt, fully stir for 30 minutes and then heat up to 55°C to completely dissolve the metal salt to obtain a metal salt solution;

[0032] (2) Under continuous mechanical stirring, add 10 g of PEG to the metal salt solution obtained in step (1), and then continue to stir for 30 minutes to obtain reaction solution A, and the average relative molecular weight of the PEG is 2000;

[0033] (3) Under continuous mechanical stirring, slowly add 50 mL of 15% H in the reaction solution A obtained in step (2). 2 C 2 o 4 solution, and then raise the temperature to 90°C, and r...

Embodiment 2

[0036] A kind of anode material 0.5Li for high-capacity lithium-ion battery 2 MnO 3 0.5LiMn 1 / 3 Ni 1 / 3 co 1 / 3 o 2 The preparation method comprises the following steps:

[0037] (1) Under stirring conditions, add 60 mL of deionized water to a 250 mL high-necked beaker, then add 5.2 g of lithium acetate dihydrate, 5.2 g of manganese acetate tetrahydrate, 1.3 g of nickel acetate tetrahydrate and 1.3 g of acetic acid tetrahydrate For cobalt, fully stir for 30 minutes and then heat up to 55°C to completely dissolve the metal salt to obtain a metal salt solution;

[0038] (2) Under continuous mechanical stirring, add 10 g of PEG to the metal salt solution obtained in step (1), and then continue to stir for 30 min to obtain reaction solution A, at which time the average relative molecular weight of PEG is 400;

[0039] (3) Under continuous mechanical stirring, slowly add 50 mL of 15% H in the reaction solution A obtained in step (2). 2 C 2 o 4 solution, and then raise the te...

Embodiment 3

[0042] A kind of anode material 0.5Li for high-capacity lithium-ion battery 2 MnO 3 0.5LiMn 1 / 3 Ni 1 / 3 co 1 / 3 o 2 The preparation method comprises the following steps:

[0043] (1) Under stirring conditions, add 70mL deionized water to a 250mL high-necked beaker, then add 5.2g lithium acetate dihydrate, 5.2g manganese acetate tetrahydrate, 1.3g nickel acetate tetrahydrate and 1.3g acetic acid tetrahydrate For cobalt, fully stir for 30 minutes and then heat up to 55°C to completely dissolve the metal salt to obtain a metal salt solution;

[0044] (2) Under continuous mechanical stirring, add 15g PEG to the metal salt solution obtained in step (1), then continue stirring for 30min to obtain reaction solution A, and the average relative molecular weight of PEG is 600 now;

[0045] (3) Under continuous mechanical stirring, slowly add 50 mL of 15% H in the reaction solution A obtained in step (2). 2 C 2 o 4 solution, and then raise the temperature to 90°C, and react for 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| discharge efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com