Injectable active bone-repair material and preparation method thereof

A technology for bone repair and activity, applied in medical science, prostheses, coatings, etc., can solve problems such as poor matching between degradation rate and bone reconstruction rate, unfavorable osteoblast ingrowth and blood vessel growth, small pore size and porosity, etc. , to achieve the effect of good osteoconductivity, good surface activity and biocompatibility, good plasticity and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

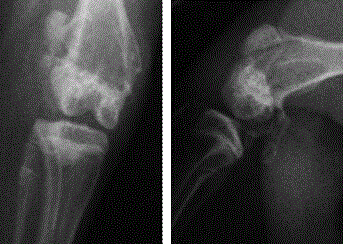

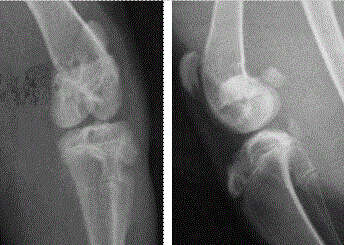

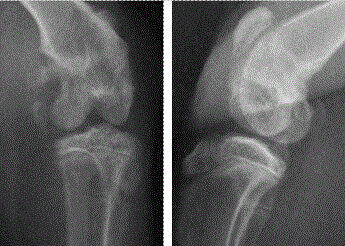

Image

Examples

Embodiment 1

[0033] The use of the injectable active bone repair material of embodiment 1

[0034] Fully blend the obtained powdery injectable active bone repair material with water for injection at a ratio of 0.8ml / g (liquid-solid ratio) to form a pasty injectable active bone repair material body with an appropriate viscosity that meets the injection requirements After that, it can be used by injection with the corresponding syringe.

[0035] Experimental results show that the initial setting time (injectable time) of the injectable active bone repair material is generally 5 minutes to 6 minutes, and the final setting time (curing time) is 15 minutes.

[0036] The experimental results show that the compressive strength of the injectable active bone repair material after solidification can reach 28MPa, exceeding the compressive strength of human cancellous bone. The results of experimental testing show that the porosity after curing is between 20%-30%, and the pore diameter is between...

Embodiment 2

[0039] The use of the injectable active bone repair material of embodiment 2

[0040] Fully blend the obtained powdery injectable active bone repair material with water for injection at a ratio of 0.8ml / g (liquid-solid ratio) to form a pasty injectable active bone repair material body with an appropriate viscosity that meets the injection requirements After that, it can be used by injection with the corresponding syringe.

[0041] Experimental results show that the initial setting time (injectable time) of the injectable active bone repair material is generally 5 minutes to 6 minutes, and the final setting time (curing time) is 16 minutes.

[0042] The experimental results show that the compressive strength of the injectable active bone repair material after solidification can reach 28MPa, exceeding the compressive strength of human cancellous bone. The results of experimental testing show that the porosity after curing is between 20%-30%, and the pore diameter is between...

Embodiment 3

[0045] The use of the injectable active bone repair material of embodiment 3

[0046] Fully blend the obtained powdery injectable active bone repair material with water for injection at a ratio of 0.8ml / g (liquid-solid ratio) to form a pasty injectable active bone repair material body with an appropriate viscosity that meets the injection requirements After that, it can be used by injection with the corresponding syringe.

[0047] Experimental results show that the initial setting time (injectable time) of the injectable active bone repair material is generally 5 minutes to 6 minutes, and the final setting time (curing time) is 16 minutes.

[0048] The experimental results show that the compressive strength of the injectable active bone repair material after solidification can reach 28MPa, exceeding the compressive strength of human cancellous bone. The results of experimental testing show that the porosity after curing is between 20%-30%, and the pore diameter is between...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com