VCM (Vinyl Chloride Monomer) rectification separation device special for high-boiling residues and separation method

A technology for rectification separation and high boiling substances, which is applied in the field of special VCM distillation and separation devices for high boiling substances, can solve the problems of environmental pollution, inability to meet the needs of high-yield continuous production, high impurity content, etc., to reduce environmental pollution, Good purification and decolorization effect, easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

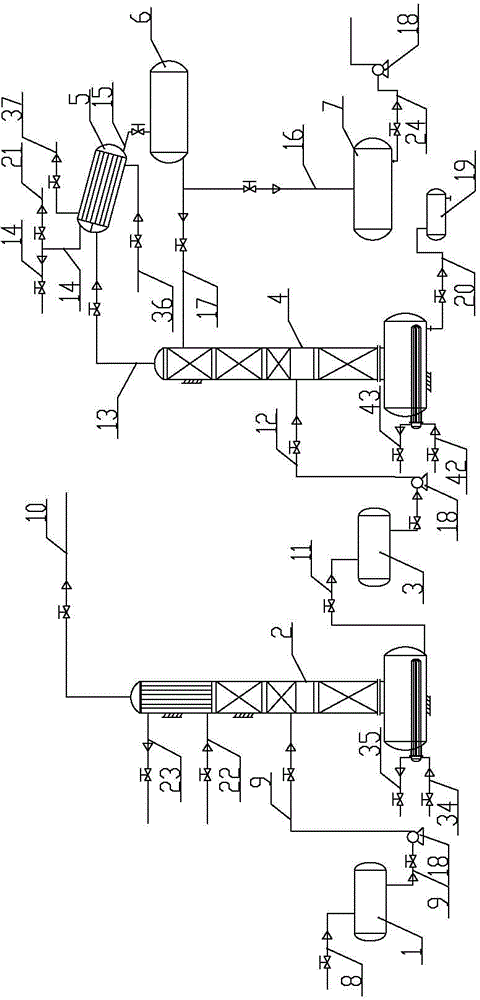

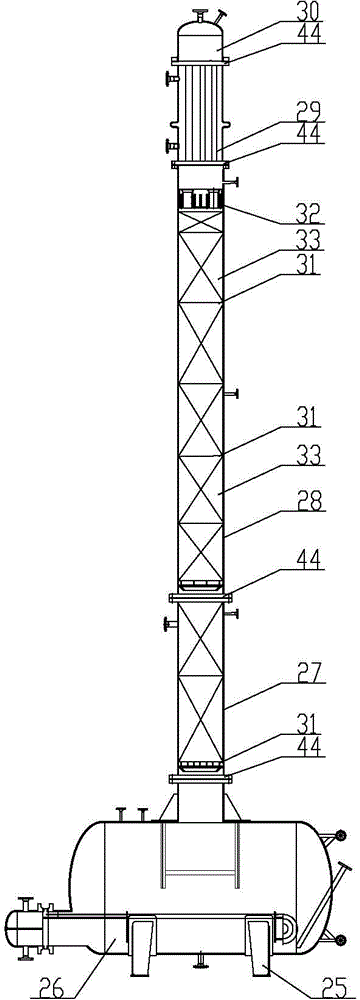

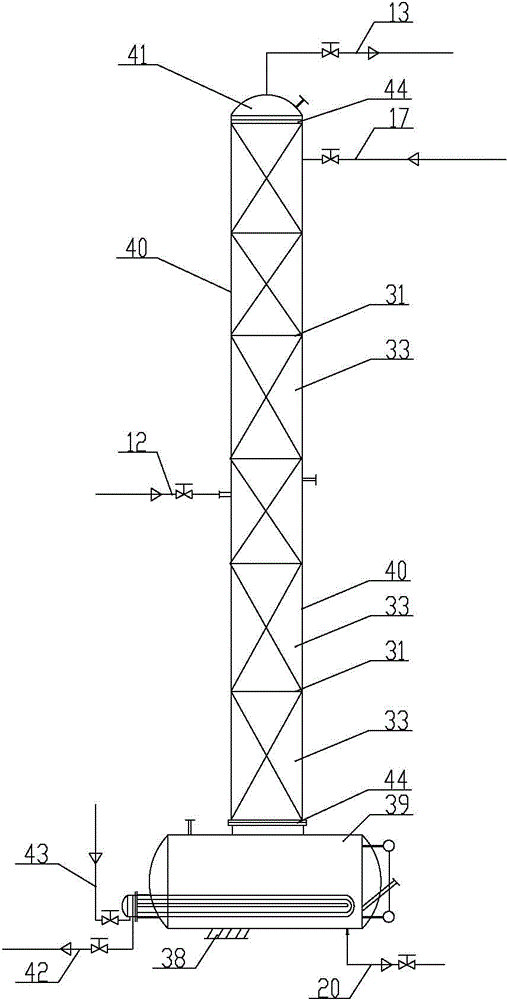

[0024] Embodiment 1, as attached figure 1 As shown, the special VCM rectification and separation device for high boilers includes a high boiler storage tank 1, a separation tower 2, an intermediate tank 3, a low boiling column 4, a condenser 5, a reflux tank 6 and a product storage tank 7; The feed end of the material storage tank 1 is fixedly connected with a feed pipe 8, the discharge end of the high boiling material storage tank 1 and the feed end of the separation tower 2 are fixedly connected together through the first pipeline 9, and the gas phase of the separation tower 2 The outlet end is fixedly connected with the first gas outlet pipe 10, the liquid phase outlet end of the separation tower 2 and the feed end of the intermediate tank 3 are fixedly connected together by the second pipeline 11, the discharge end of the intermediate tank 3 and the low boiling column 4 The feed end of the feed end is fixedly connected together by the third pipeline 12, the gas phase outle...

Embodiment 2

[0032] Embodiment 2, as attached figure 1Shown, the separation method of this special-purpose VCM rectification and separation device for high boilers is carried out as follows: the first step, the high boilers in the high boiler storage tank 1 pass through the first pipeline 9, pump 18 and separation tower 2 The feed end enters the first bottom reboiler 26 for heating, the temperature of the first bottom reboiler 26 of the separation tower 2 is 73°C to 77°C, and the light components in the high boilers pass through the first tower body After the filler 33 in 27, the filler 33 in the second tower body 28, the gas-liquid separator 32 and the tower top condenser 29, finally enter the gas cabinet through the first gas outlet pipe 10, and the high boiling matter after separation is left in the first In a bottom reboiler 26; in the second step, the separated high boilers in the first bottom reboiler 26 enter the intermediate tank 3 through the second pipeline 11, and then enter the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com