Device and method for online regenerating low-temperature denitration catalyst by rotary fixed bed

A low-temperature denitration and catalyst technology is applied in the field of preparation of low-temperature denitration catalysts, which can solve the problems of difficult online regeneration, easy deactivation of low-temperature denitration catalysts, etc., and achieves the effect of reducing the layout, realizing online continuous denitration regeneration, and good air tightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below with reference to the accompanying drawings.

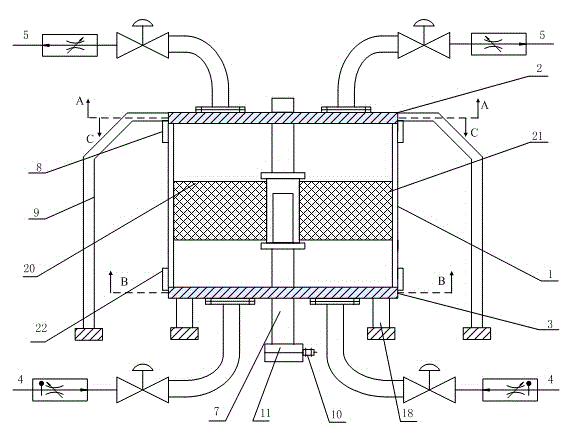

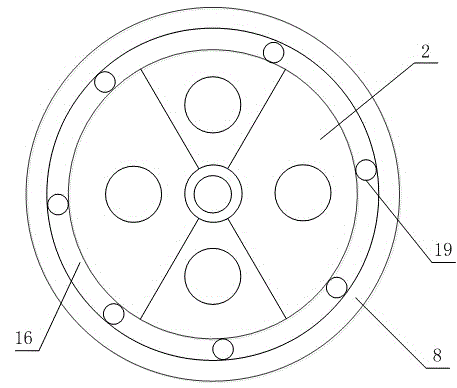

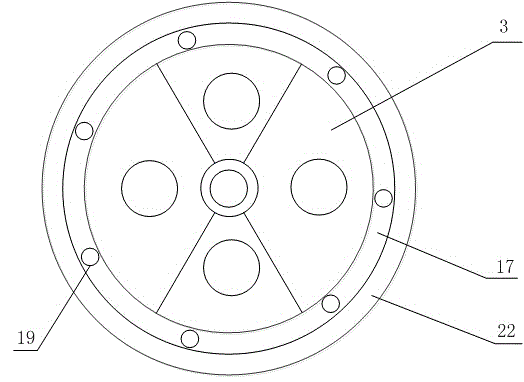

[0031] Such as Figure 1 to Figure 4 As shown, a device for on-line regeneration of a rotary fixed bed low-temperature denitrification catalyst of the present invention includes a fixed bed reactor 1, an upper end cover 2, a lower end cover 3, four intake pipes 4, four exhaust pipes 5, and a drive shaft 7. The first seal 8 , the support frame 9 , the motor 10 , the coupling 11 , the frame 18 and the second seal 22 . The fixed bed reactor 1 is in the shape of a cylinder, and a bed material layer 20 is arranged in the middle of the fixed bed reactor 1 . The upper end cover 2 is connected to the top of the fixed bed reactor 1 . An upper sliding track 16 is provided on the contact surface between the extension of the bottom surface of the upper end cover 2 and the extension of the top surface of the fixed bed reactor 1 . Balls 19 are arranged in the upper sliding track 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com