Composite material of metal nano particles and microporous coordination polymer and preparation method thereof

A technology of metal nanoparticles and coordination polymers, which can be used in organic compound/hydride/coordination complex catalysts, purification with oxygenated compounds, chemical instruments and methods, etc., and can solve problems such as reduced catalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

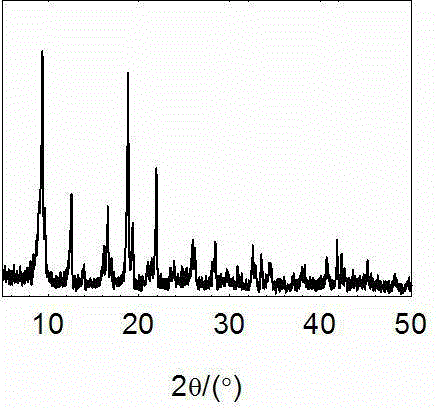

[0035] Example 1 A composite material of metal nanoparticles and microporous coordination polymers, characterized in that the metal nanoparticles are palladium or platinum nanoparticles, and the microporous coordination polymers are iron-based microporous coordination polymers MIL- 53(Fe), MIL-53(Fe) has a topological structure, and its general formula can be written as Fe(OH)L·H 2 O, where L is an organic ligand, iron ions are connected by oxygen and the carboxyl group of the organic ligand to form a "zigzag" chain, and then these chains are connected by an organic ligand to form a 1D pore structure.

[0036] A method for preparing a composite material of metal nanoparticles and microporous coordination polymers, the steps and conditions are as follows:

[0037] Step 1, under stirring at normal temperature and pressure, 270 mg of FeCl 3 . 6H 2 O (1.0mmol) dissolved in 10ml N , N’ - Dimethylformamide (130 mmol) forms a brown solution;

[0038] Step 2, add 249mg terepht...

Embodiment 2

[0040] Example 2 A method for preparing a composite material of metal nanoparticles and microporous coordination polymers, the steps and conditions are as follows:

[0041] Step 1, under stirring at normal temperature and pressure, 414 mg of Fe(NO 3 ) 3 . 9H 2 O (1.0mmol) dissolved in 15ml N , N’ - Dimethylformamide (130 mmol) forms a brown solution;

[0042] Step 2, the brown solution prepared in step 1 was added organic ligand 332mg terephthalic acid (2mmol) until dissolved;

[0043] Step 3, adding the brown solution prepared in step 2 to a concentration of 1 mg / 1 mL of 5.7 nm metal nanoparticles platinum methanol solution, Fe(NO 3 ) 3 . 9H 2 O : H 2 The molar ratio of BDC: DMF: Pt is 1: 2: 195: 0.005, and then the brown solution is stirred for half an hour, reacted at 130°C for 24 hours, the product is separated by centrifugation at 5000 rpm for 10 minutes, and washed three times with ethanol , and dried to obtain a composite material of platinum nanoparticl...

Embodiment 3

[0044] Example 3 A method for preparing a composite material of metal nanoparticles and microporous coordination polymers, the steps and conditions are as follows:

[0045] Step 1, under stirring at normal temperature and pressure, 414 mg of Fe(NO 3 ) 3 . 9H 2 O (1.0mmol) dissolved in 15ml N , N’ - Dimethylformamide (130 mmol) forms a brown solution;

[0046] Step 2, add 166 mg of terephthalic acid (1 mmol) as an organic ligand to the brown solution prepared in step 1 until dissolved;

[0047] Step 3, adding the brown solution prepared in step 2 to a concentration of 1 mg / 1 mL of 8.2 nm metal nanoparticles platinum methanol solution, Fe(NO 3 ) 3 . 9H 2 O: H 2 The molar ratio of BDC:DMF is 1:2:195:0.005, and then the brown solution is stirred for half an hour, and the product is separated by centrifugation at 5000 rpm for 10 minutes, washed with ethanol three times, and dried to obtain platinum nanoparticles and iron-based Composite materials of microporous coor...

PUM

| Property | Measurement | Unit |

|---|---|---|

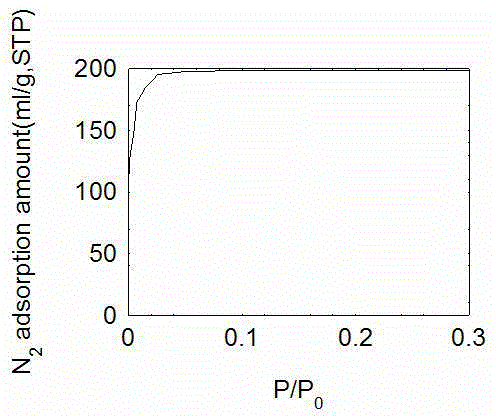

| specific surface area | aaaaa | aaaaa |

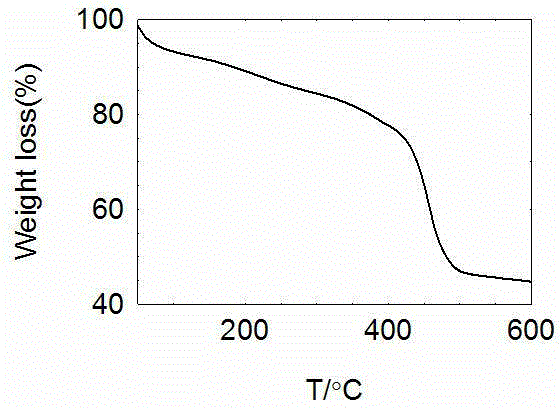

| thermal stability | aaaaa | aaaaa |

| thermal stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com