Method for transforming waste paper or fiber fabric into graphene-carbon fiber composite material

A technology of fiber fabrics and composite materials, applied in the field of graphene-carbon fiber composite materials, can solve the problems of difficult processing and application of carbon fiber and graphene axial composite nanomaterials, achieve considerable market application prospects, and suppress the effect of temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

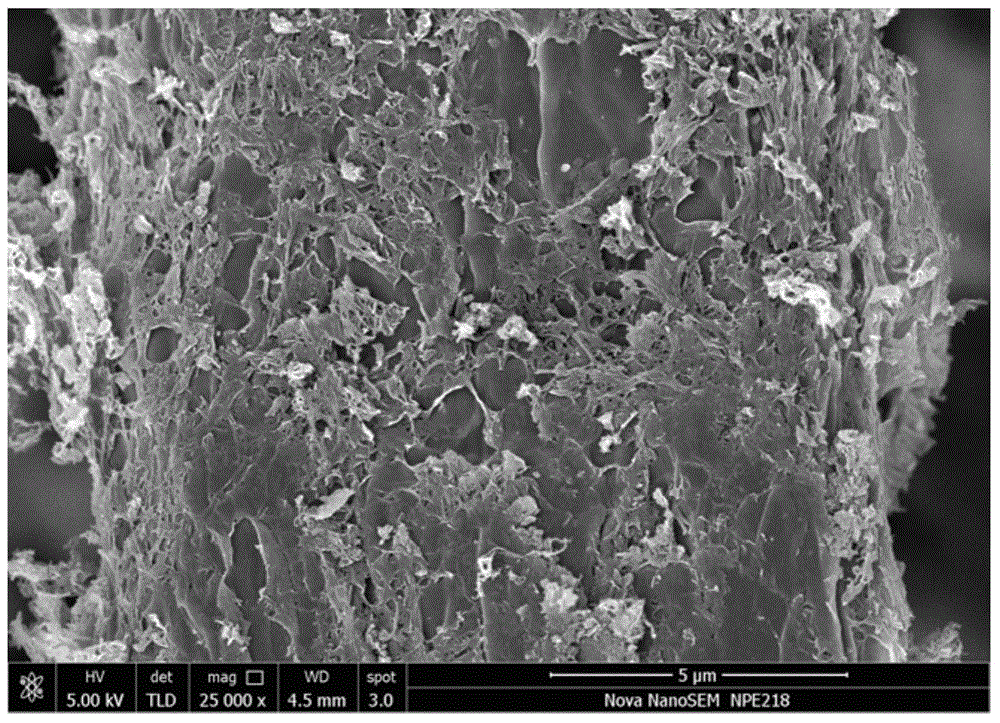

[0019] Control the mass ratio of newspaper and urea to 1:40, place the mixture of newspaper and urea in a nitrogen-protected muffle furnace, calcinate at 1000°C for 12 hours, and finally cool naturally to obtain a composite material with a graphene-modified carbon fiber surface.

Embodiment 2

[0021] Control the mass ratio of A4 printing paper and urea to 1:40, place the mixture of newspaper and urea in a nitrogen-protected muffle furnace, calcinate at 1000°C for 12 hours, and finally cool naturally to obtain a composite material with a graphene-modified carbon fiber surface.

Embodiment 3

[0023] Control the mass ratio of napkin and urea to 1:40, place the mixture of newspaper and urea in a nitrogen-protected muffle furnace, calcinate at 1000°C for 12 hours, and finally cool naturally to obtain a composite material with a graphene-modified carbon fiber surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com