Preparation method of sphere-like and bookmark-shaped cuprous oxide nano-particles

A nano-cuprous oxide and nano-particle technology, which is applied in the direction of copper oxide/copper hydroxide, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problem of difficult to prepare small particle products, increase adsorption and photocatalytic degradation ability, increase the surface area, etc., to achieve good photocatalytic performance and gas sensing characteristics, short reaction time, and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

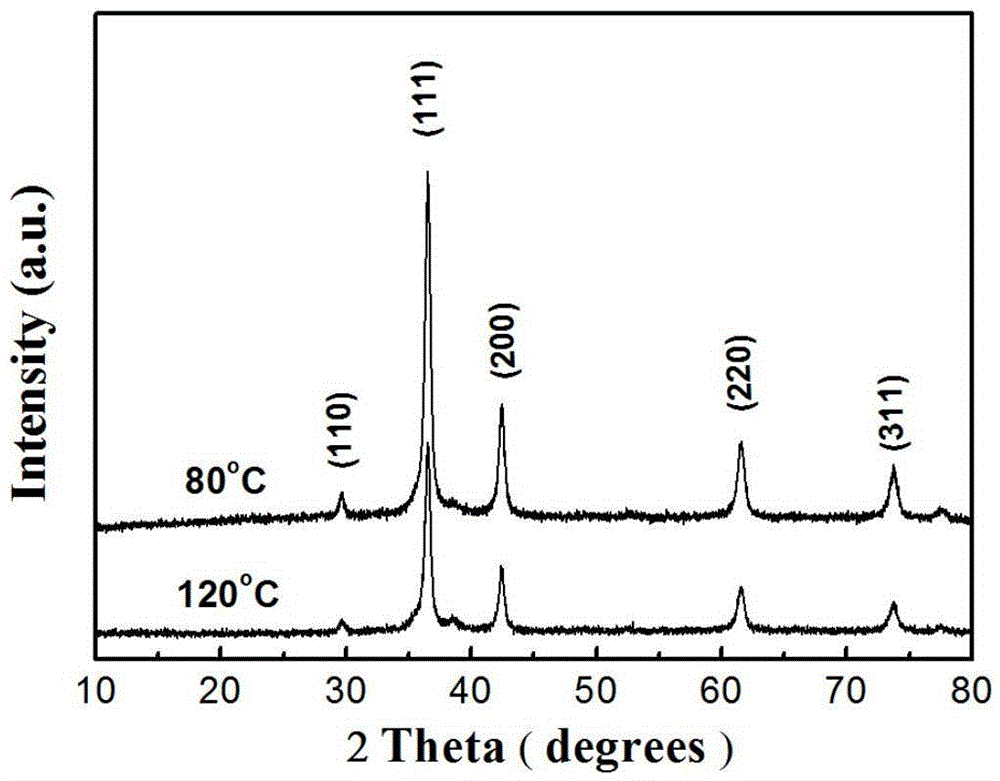

[0030] Embodiment 1: The raw materials and combinations thereof for preparing the nano-cuprous oxide particles are prepared as follows: copper acetate: 0.4g ± 0.001g, N-N dimethylformamide (DMF): 60ml ± 0.5mL, polyvinylpyrrolidone (PVP) : 0.165g±0.001g, sodium borohydride: 0.04g±0.001g;

[0031] The concrete steps of preparation method are:

[0032] (1) Dissolve 0.4g copper acetate into 60ml N-N dimethylformamide;

[0033] (2) Add 0.165g of PVP (molecular weight: 50,000) into the above solution and stir vigorously;

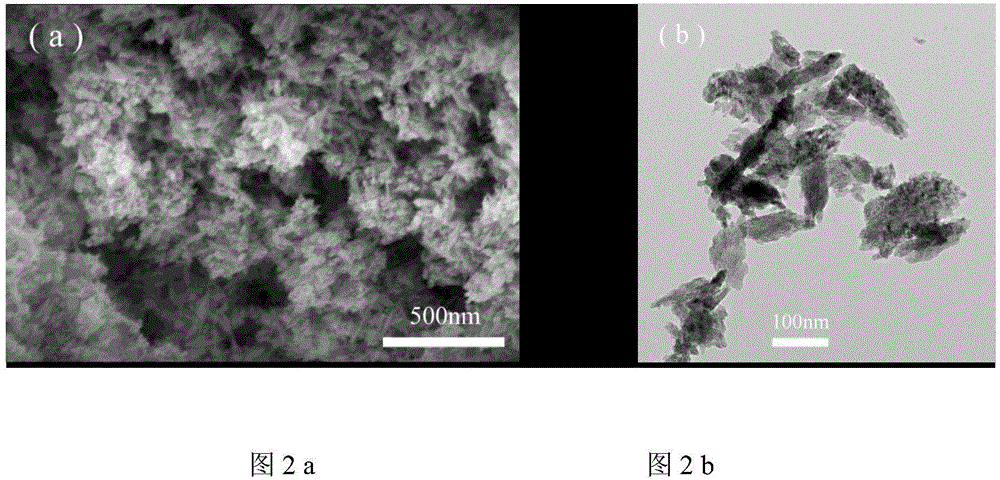

[0034] (3) Then add 0.04g of sodium borohydride to the above solution, react in a water bath at 80°C for 25 minutes, and in an oil bath at 120°C for 22 minutes, orange or yellow particles appear, indicating Cu 2 O generate;

[0035] (4) will contain Cu 2 The solid-liquid two-phase of O was centrifuged at high speed to obtain Cu 2 O solid particles, then cross-wash Cu with absolute alcohol and deionized water 2 O particles several times to remove other impuri...

Embodiment 2

[0041] (1) Dissolve 0.4g copper acetate into 60ml N-N dimethylformamide;

[0042] (2) Add 0.165g of PVP (molecular weight: 50,000) into the above solution and stir vigorously;

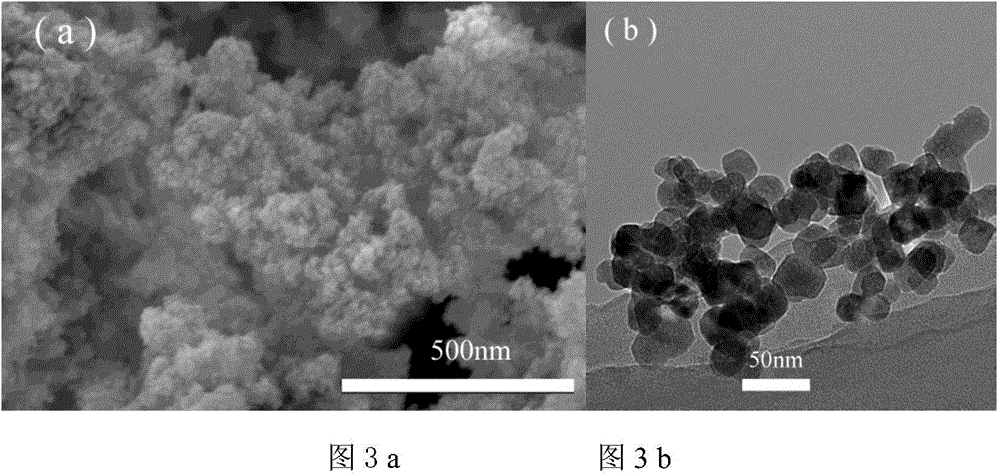

[0043] (3) Then add 0.04g of sodium borohydride to the above solution, react in a water bath at 80°C for 25 minutes, and in an oil bath at 120°C for 22 minutes, orange or yellow particles appear, indicating Cu 2 O generate;

[0044] (4) will contain Cu 2 The solid-liquid two-phase of O was centrifuged at high speed to obtain Cu 2 O solid particles, then cross-wash Cu with absolute alcohol and deionized water 2 O particles several times to remove other impurities in the reaction process;

[0045] (5) Wet Cu 2 O is placed in a vacuum drying oven and dried under vacuum at 60°C for 4 hours to obtain high-purity Cu 2 O-type spherical nanoparticles.

[0046] Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap