Method for recycling phosphorus from sludge by utilizing MFC

A technology for sludge and sludge digestion liquid, applied in the field of sludge resource utilization, can solve problems such as being in the initial stage, and achieve the effects of efficient recovery, alleviation of water eutrophication, and reduction of construction and operation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1: Method for recovering phosphorus from sludge using MFC

[0043] 1) Anaerobic digestion of phosphorus-containing sludge for 12 days, the phosphorus in the sludge is released under anaerobic conditions, and enriched in the sludge digestion solution in a phosphate dissolved state; collect the supernatant of the sludge digestion solution , that is, the phosphorus-containing sludge digestion solution was obtained, and the relevant index test results are shown in Table 1.

[0044] Among them, anaerobic digestion refers to the process in which the biodegradable organic matter in the sludge is decomposed into carbon dioxide, methane and water by facultative bacteria and anaerobic bacteria under anaerobic conditions, so that the sludge is stabilized. Anaerobic digestion is the basic process of sludge treatment, and the digestion time can range from a few days to dozens of days.

[0045] Table 1 Properties of phosphorus-containing sludge digestate

[0046]

[00...

Embodiment 2

[0056] Example 2 Optimization of pH value

[0057] According to the method of utilizing MFC to recover phosphorus from sludge described in Example 1, the optimal pH value of the electrolyte was studied.

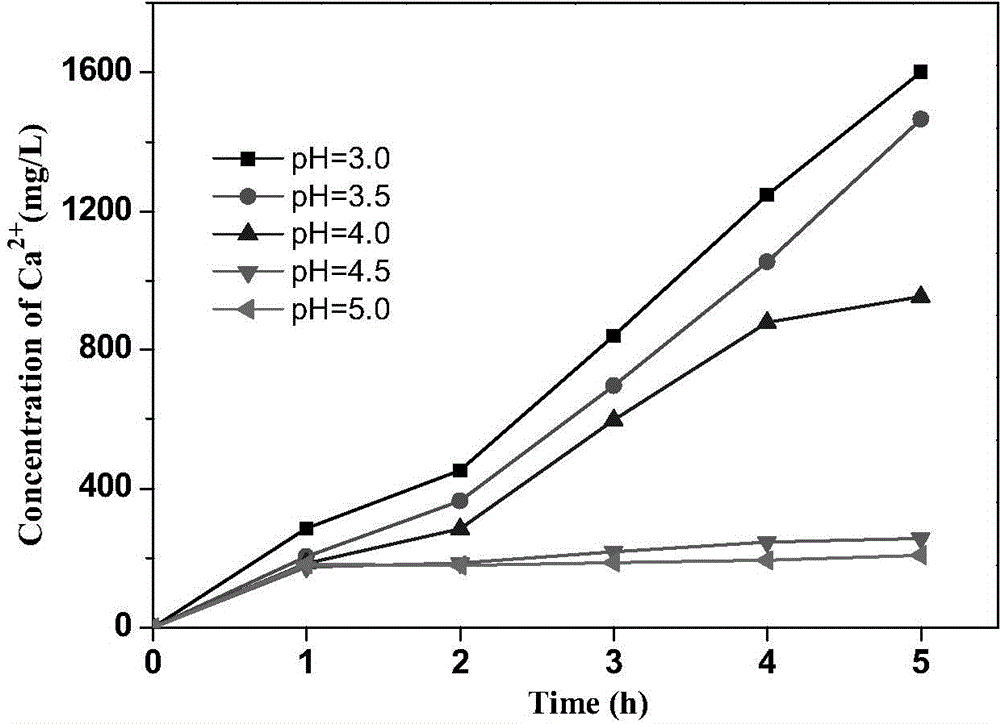

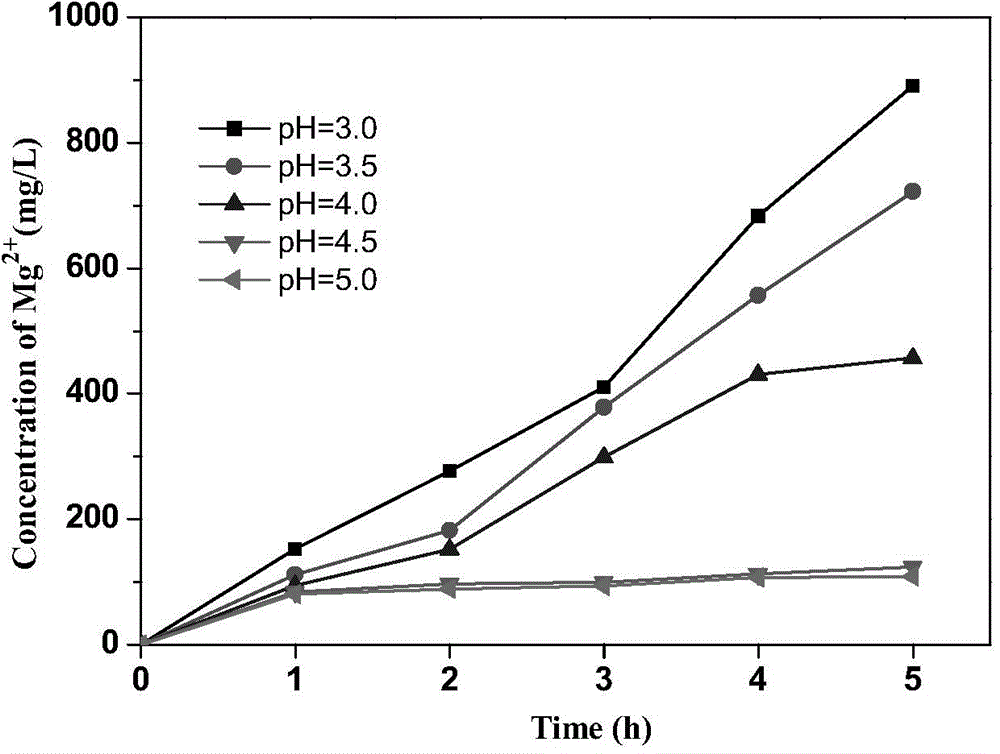

[0058] Take 200 mL of phosphorus-containing sludge digestion solution filtered through a 0.45 μm filter membrane into five 500 mL beakers, add 10 g of dolomite, adjust and control the pH of the digestion solution with hydrochloric acid to 3.0, 3.5, 4.0, 4.5 and 5.0, acidify with slow stirring for 5 hours, take samples every hour to measure Ca in the digestive juice 2+ , Mg 2+ Concentration, to investigate the effect of different pH on the dissolution of calcium and magnesium in phosphorus-containing sludge digestion solution. The result is as figure 1 and figure 2 shown.

[0059] Depend on figure 1 and figure 2 It can be seen that under different pH conditions, Ca 2+ and Mg 2+ The dissolution has the same change trend, and they all increase with the increase of a...

Embodiment 3

[0060] Example 3 Optimization of solid-liquid ratio of dolomite and digestive juice

[0061] According to the method of utilizing MFC to reclaim phosphorus from sludge as described in Example 1, the optimum solid-to-liquid ratio of dolomite and digestive liquid in the electrolyte was studied.

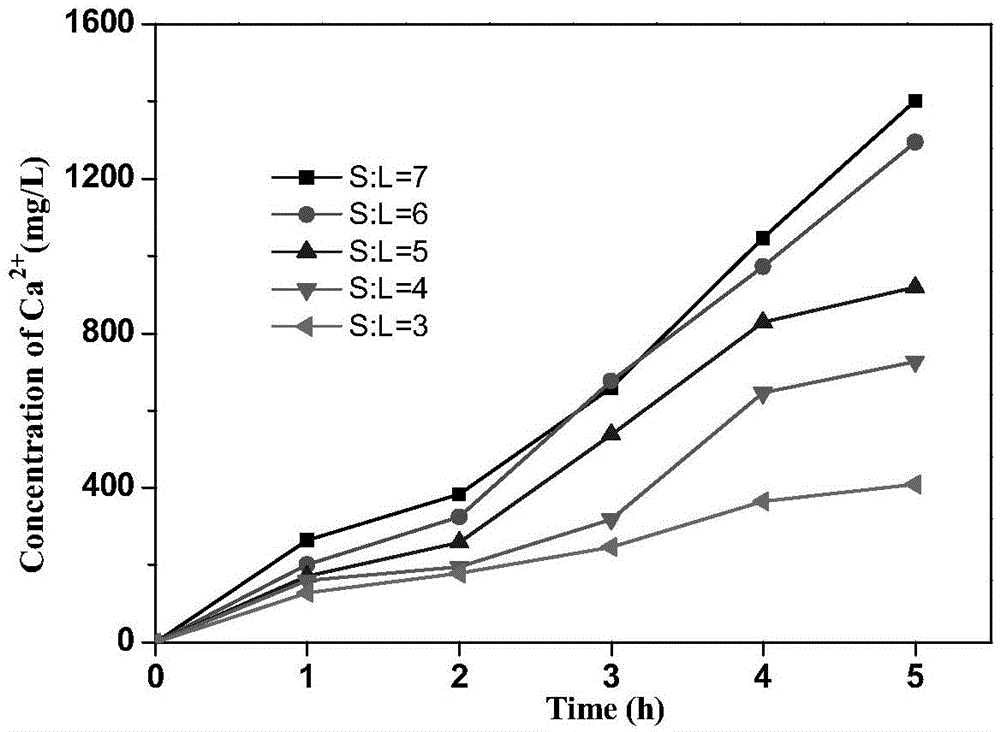

[0062] Take 200 mL of phosphorus-containing sludge digestion solution filtered through a 0.45 μm filter membrane into five 500 mL beakers, and add 6 g, 8 g, 10 g, 12 g and 14 g of dolomite in sequence, so that the solidification of dolomite and digestion solution The liquid ratios are (3g: 100mL), (4g: 100mL), (5g: 100mL), (6g: 100mL) and (7g: 100mL), add hydrochloric acid to the beaker to adjust and control the pH of the digestive solution to 4.0, and stir slowly Acidify for 5 hours, and dissolve the dolomite, and take samples every hour to measure Ca in the digestive juice 2+ , Mg 2+ Concentration, to investigate the effect of different solid-liquid ratios on the dissolution of ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com