Preparation method for producing autoclaved aerated concrete block by using antimony ore tailing

A concrete block, autoclaved and aerated technology, which is applied in ceramic products, climate sustainability, sustainable waste treatment, etc., can solve the problems of large proportion, insignificant material performance advantages, high product cost, etc., and achieve light weight, The effect of prolonging the digestion time and improving the masonry strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

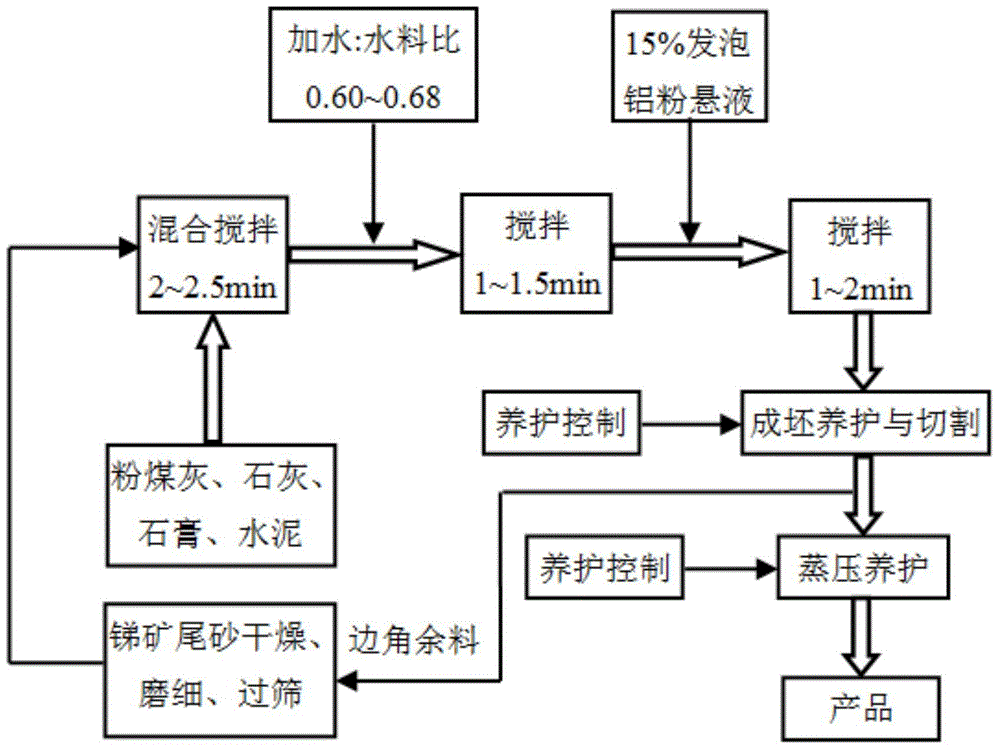

Method used

Image

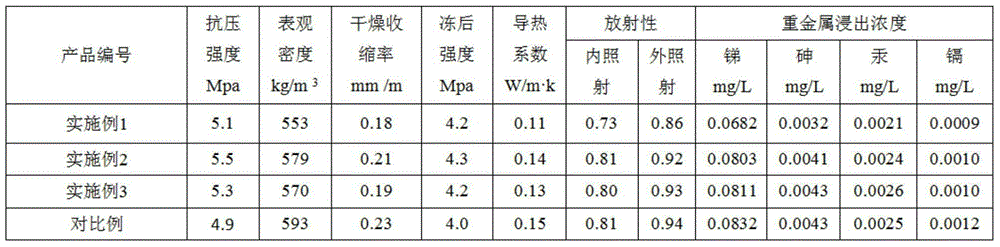

Examples

Embodiment 1

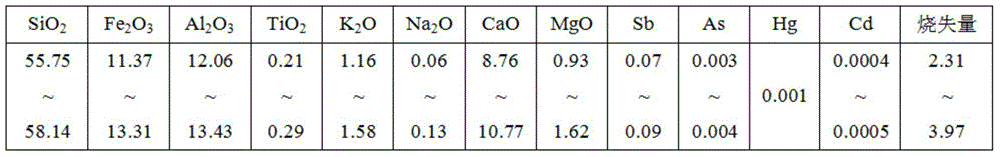

[0031] (1) Take the tailings of a certain antimony ore and form and maintain it into a billet and cut the leftovers into a dryer with a temperature of 130°C to 150°C to dry, and send the dried mixture to a ball mill to grind it finely, and finally pass it through a 0.150mm After being sieved by the sieving machine, it is ready for use.

[0032] (2) According to the preparation process of the autoclaved aerated concrete block of the present invention, respectively weigh antimony ore tailings, fly ash, quicklime powder, gypsum, 425# ordinary Portland cement, Water and foamed aluminum powder (manually adjusted to 15% foamed aluminum powder suspension) for use; then put antimony ore tailings-fly ash-quicklime powder-gypsum-cement into the machine model NJ-160A Stir in a mixer at 300r / min for 2.5min, then add a certain mass of water to the mixer and stir at 500r / min for 1.5min, and finally add foamed aluminum powder suspension and stir at 800r / min for 2min; the mass percentages of ...

Embodiment 2

[0036] (1) Take the tailings of a certain antimony ore and form and maintain it into a billet and cut the leftovers into a dryer with a temperature of 130°C to 150°C to dry, and send the dried mixture to a ball mill to grind it finely, and finally pass it through a 0.150mm After being sieved by the sieving machine, it is ready for use.

[0037] (2) According to the preparation process of the autoclaved aerated concrete block of the present invention, respectively weigh antimony ore tailings, fly ash, quicklime powder, gypsum, 425# ordinary Portland cement, water and foaming Aluminum powder (artificially modulated into 15% foamed aluminum powder suspension) is for use; then the order of antimony ore tailings-fly ash-quicklime powder-gypsum-cement is dropped into the mechanical mixer of NJ-160A and mixed with Stir at 300r / min for 2min, then add a fixed mass of water at about 25°C in the mixer and stir at 500r / min for 1.5min, and finally add foam aluminum powder suspension and st...

Embodiment 3

[0041] (1) Take the tailings of a certain antimony ore and form and maintain it into a billet and cut the leftovers into a dryer with a temperature of 130°C to 150°C to dry, and send the dried mixture to a ball mill to grind it finely, and finally pass it through a 0.150mm After being sieved by the sieving machine, it is ready for use.

[0042] (2) According to the preparation process of the autoclaved aerated concrete block of the present invention, respectively weigh antimony ore tailings, fly ash, quicklime powder, gypsum, 425# ordinary Portland cement, Water and foamed aluminum powder suspension (manually adjusted to 15% foamed aluminum powder suspension) for use; then put antimony ore tailings-fly ash-quicklime powder-gypsum-cement in the order of NJ-160A Stir in a mechanical mixer at 300r / min for 2min, then add a certain mass of water to the mixer and stir at 500r / min for 1.5min, and finally add foamed aluminum powder suspension and stir at 800r / min for 1min; the mass pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com