A precise metering method for catalyst configuration of ultra-high molecular weight polyethylene unit

A technology of ultra-high molecular weight and polyethylene, which is applied in the direction of chemical instruments and methods, mixer accessories, dissolution, etc., can solve the problems of insufficient measurement accuracy, failure to achieve results, and inability to initiate reactions, etc. Small, space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

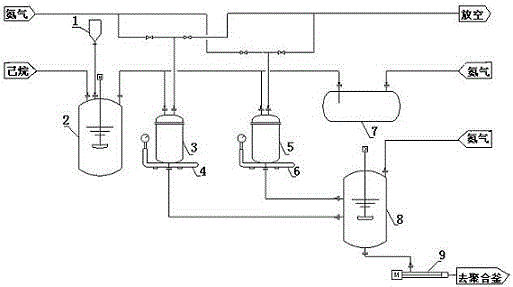

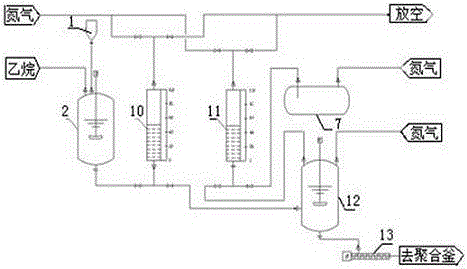

[0029] Combine below figure 2 The process flow of an ultra-high molecular weight polyethylene unit catalyst configuration accurate metering method is described as follows:

[0030] The configuration of the catalyst is divided into the configuration of the main catalyst and the configuration of the co-catalyst.

[0031] Step 1: First, the main catalyst is contained in the main catalyst container 1 with 10kg of main catalyst (solid powder). The main catalyst is provided by the Shanghai Institute of Organic Chemistry, Chinese Academy of Sciences, a single-site catalyst for UHMWPE, and the secondary catalyst is triethylaluminum Al(C 2 h 5 ) 3 After the catalyst is provided, it is configured into a solution according to the ratio. The main components of the main catalyst are titanium, aluminum, magnesium, chlorine, oxygen, hydrocarbon, electron donor, solid powder, light brown or light gray.

[0032] Use 0.6MPa high-purity nitrogen pressure to send it to the receiving tank 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com