Calcium carbonate surface modifier

A surface modifier, calcium carbonate technology, applied in the direction of inorganic pigment treatment, dyeing organosilicon compound treatment, chemical instruments and methods, etc., can solve the problems of cumbersome synthesis process, not very strong, high cost, etc., and achieve good comprehensive mechanical properties , good surface modification effect and strong interfacial binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

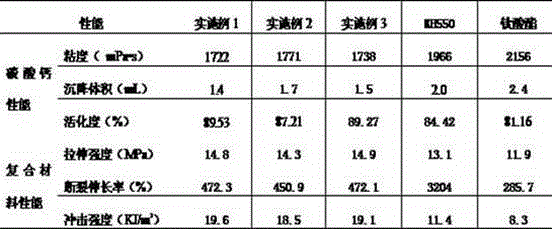

Examples

Embodiment 1

[0020] A calcium carbonate surface modifier is a rare earth-silane surface modifier prepared through coordination reaction using lanthanum oxide and gamma-mercaptopropyltrimethoxysilane as raw materials.

[0021] The preparation steps include: accurately weighing lanthanum oxide and γ-mercaptopropyltrimethoxysilane with a substance ratio of 1:6, adding them into a reaction vessel, rapidly raising the temperature to 130°C, stirring, and reacting for 3 hours to obtain rare earth - Silane surface modifiers.

Embodiment 2

[0023] A calcium carbonate surface modifier is a rare earth-silane surface modifier prepared through coordination reaction using lanthanum oxide and 3-aminopropyltriethoxysilane as raw materials.

[0024] The preparation steps include: accurately weighing lanthanum oxide and 3-aminopropyltriethoxysilane with a substance ratio of 1:6, adding them into a reaction vessel, rapidly raising the temperature to 130°C, stirring, and reacting for 3 hours to obtain Rare earth-silane surface modifier.

Embodiment 3

[0026] A calcium carbonate surface modifier is a rare earth-silane surface modifier prepared through coordination reaction using lanthanum oxide and gamma-mercaptopropyltrimethoxysilane as raw materials.

[0027] The preparation steps include: accurately weighing lanthanum oxide and γ-mercaptopropyltrimethoxysilane with a substance ratio of 1:7, adding them into a reaction vessel, rapidly raising the temperature to 120°C, stirring, and reacting for 3 hours to prepare the rare earth - Silane surface modifiers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com