Co(OH)2/TiO2 nanotube array composite material and preparation method thereof

A technology of nanotube array and composite material, which is applied in the field of Co2/TiO2 nanotube array composite material and its preparation method, which can solve the problems of high pressure, achieve the effect of increased specific capacitance, strong interface binding force, and shortened preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

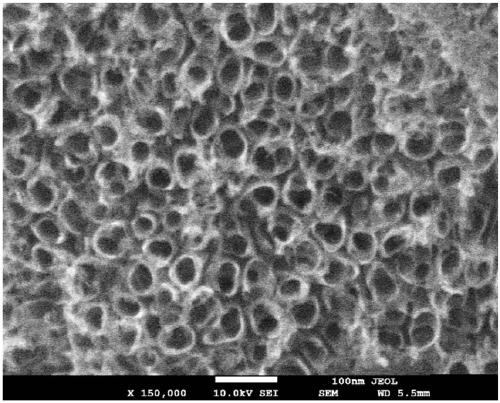

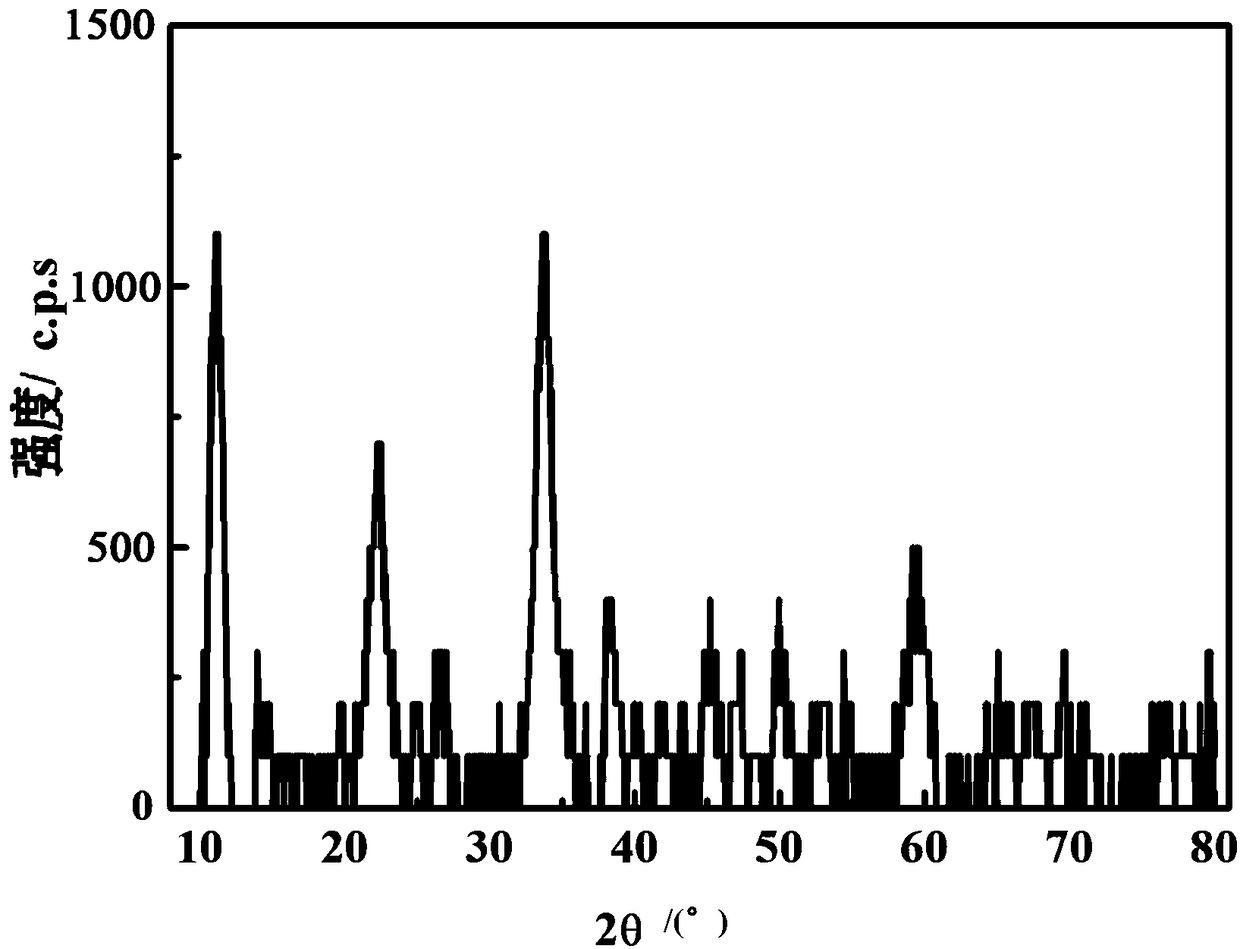

[0040] A Co(OH) 2 / TiO 2 The preparation method of nanotube array composite material comprises the following steps:

[0041] Step 1: Preparation of TiO by anodizing 2 nanotube array

[0042] (1) The pure titanium metal sheet is first polished with No. 5 sandpaper, chemically corroded for 5 minutes, and rinsed with water for 15 minutes to obtain the pretreated pure titanium metal sheet;

[0043] Among them, the reagents used for chemical corrosion are: HF, HNO 3 and H 2 O mixture; wherein, by volume, HF is 10%, HNO 3 is 40%, and the balance is water.

[0044] (2) Take the pretreated pure titanium metal sheet as the anode and pure iron as the cathode, add electrolyte, and conduct electrolysis to obtain electrolyzed TiO 2 Nanotube array; wherein, the electrolysis voltage is 20V, the electrolysis time is 1h, and the electrolyte is NH 4 A mixed aqueous solution of F and glycerol, in which, by mass percentage, NH 4 F is 0.5%, glycerol is 20%, and the balance is water;

[0...

Embodiment 2

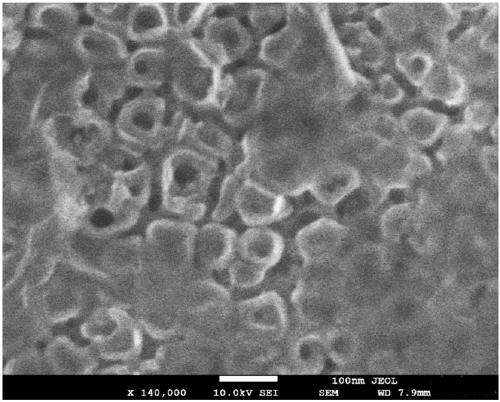

[0061] A Co(OH) 2 / TiO 2 The preparation method of nanotube array composite material comprises the following steps:

[0062] Step 1: Preparation of TiO by anodizing 2 nanotube array

[0063] (1) The pure titanium metal flakes are first polished with No. 5 sandpaper, chemically corroded for 6 minutes, and rinsed with water for 15 minutes to obtain the pretreated pure titanium metal flakes;

[0064] Among them, the reagents used for chemical corrosion are: HF, HNO 3 and H 2 O mixture; wherein, by volume, HF is 5%, HNO 3 is 45% and the balance is water.

[0065] (2) Take the pretreated pure titanium metal sheet as the anode and pure iron as the cathode, add electrolyte, and conduct electrolysis to obtain electrolyzed TiO 2 Nanotube array; wherein, the electrolysis voltage is 10V, the electrolysis time is 2h, and the electrolyte is NH 4 A mixed aqueous solution of F and glycerol, in which, by mass percentage, NH 4 F is 0.6%, glycerol is 30%, and the balance is water;

[...

Embodiment 3

[0080] A Co(OH) 2 / TiO 2 The preparation method of nanotube array composite material comprises the following steps:

[0081] Step 1: Preparation of TiO by anodizing 2 nanotube array

[0082] (1) The pure titanium metal sheet is first polished with No. 5 sandpaper, chemically corroded for 3 minutes, and rinsed with water for 10 minutes to obtain the pretreated pure titanium metal sheet;

[0083] Among them, the reagents used for chemical corrosion are: HF, HNO 3 and H 2 O mixture; wherein, by volume, HF is 5%, HNO 3 is 45% and the balance is water.

[0084] (2) Take the pretreated pure titanium metal sheet as the anode and pure iron as the cathode, add electrolyte, and conduct electrolysis to obtain electrolyzed TiO 2 Nanotube array; wherein, the electrolysis voltage is 30V, the electrolysis time is 0.5h, and the electrolyte is NH 4 A mixed aqueous solution of F and glycerol, in which, by mass percentage, NH 4 F is 0.3%, glycerol is 15%, and the balance is water;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com