Petroleum proppant and preparation method thereof

A proppant and petroleum technology, applied in chemical instruments and methods, earthwork drilling, mining fluids, etc., can solve the problems of nickel slag polluting the environment, wasting land resources, etc., achieve low energy consumption in the preparation process, improve utilization efficiency, and increase production capacity big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

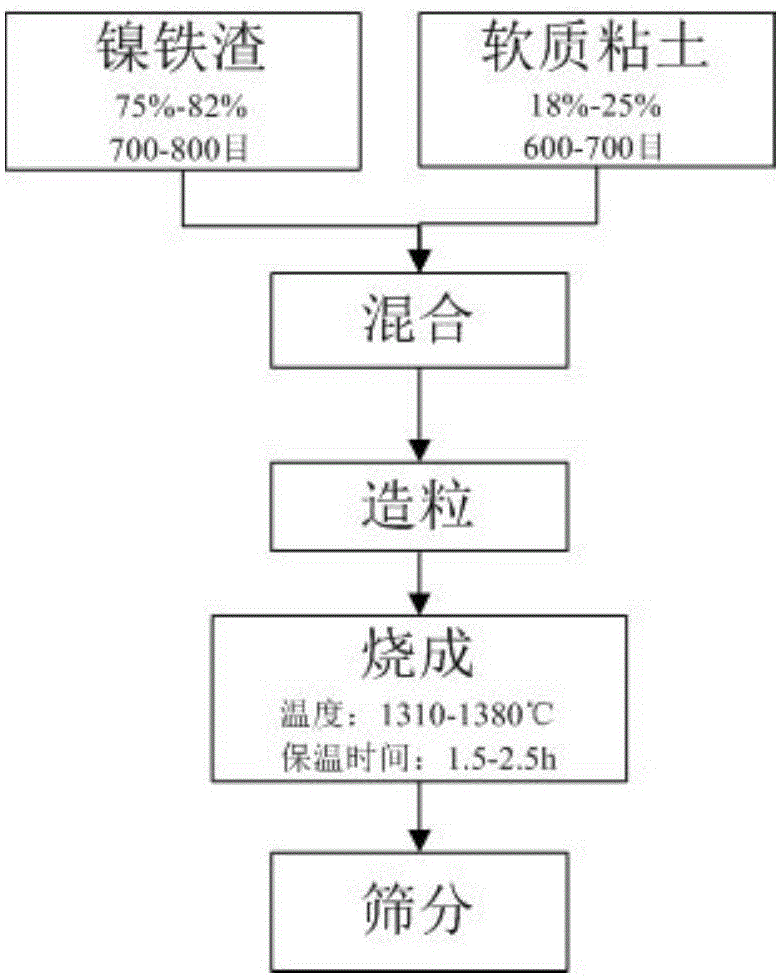

Image

Examples

Embodiment 1

[0049] A petroleum proppant is prepared from the following raw materials by weight percentage:

[0050] Ferronickel slag 80%

[0051] Soft clay 20%.

[0052] The preparation method of above-mentioned petroleum proppant, comprises the steps:

[0053] (1) Material preparation:

[0054] a. The ferronickel slag is subjected to iron removal treatment after coarse grinding, and then ground to 600-800 mesh by a micro-powder mill;

[0055] b. Dry the soft clay at a drying temperature of 150°C, and then grind it to 600-700 mesh by ball mill;

[0056] (2) Mixing: get ferronickel slag and soft clay according to the ratio of raw materials to make a mixture, and mix evenly to form a premix;

[0057] (3) Granulation: the premix obtained in step (2) is granulated by a disc granulator, and sieved to obtain semi-finished granules;

[0058] (4) Firing: Send the semi-finished product into the rotary kiln, the firing temperature is 1350°C, and the holding time is 1.5 hours;

[0059] (5) Sie...

Embodiment 2

[0061] A petroleum proppant is prepared from the following raw materials by weight percentage:

[0062] Ferronickel slag 81%

[0063] Soft clay 19%.

[0064] The preparation method of above-mentioned petroleum proppant, comprises the steps:

[0065] (1) Material preparation:

[0066] a. The ferronickel slag is subjected to iron removal treatment after coarse grinding, and then ground to 600-800 mesh by a micro-powder mill;

[0067] b. Dry the soft clay at a drying temperature of 180°C, and then grind it to 600-700 mesh by ball mill;

[0068] (2) Mixing: get ferronickel slag and soft clay according to the ratio of raw materials to make a mixture, and mix evenly to form a premix;

[0069] (3) Granulation: the premix obtained in step (2) is granulated by a disc granulator, and sieved to obtain semi-finished granules;

[0070] (4) Firing: Send the semi-finished product into the rotary kiln, the firing temperature is 1380°C, and the holding time is 1.5 hours;

[0071] (5) Sie...

Embodiment 3

[0073] A petroleum proppant is prepared from the following raw materials by weight percentage:

[0074] Ferronickel slag 75%

[0075] Soft clay 25%.

[0076] The preparation method of above-mentioned petroleum proppant, comprises the steps:

[0077] (1) Material preparation:

[0078] a. The ferronickel slag is subjected to iron removal treatment after coarse grinding, and then ground to 600-800 mesh by a micro-powder mill;

[0079] b. Dry the soft clay at a drying temperature of 110°C, and then grind it to 600-700 mesh by ball mill;

[0080] (2) Mixing: get ferronickel slag and soft clay according to the ratio of raw materials to make a mixture, and mix evenly to form a premix;

[0081] (3) Granulation: the premix obtained in step (2) is granulated by a disc granulator, and sieved to obtain semi-finished granules;

[0082] (4) Burning: Send the semi-finished product into the rotary kiln, the firing temperature is 1320°C, and the holding time is 3 hours;

[0083] (5) Siev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Broken rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com