Construction method and application of L-isoleucine producing genetically engineered bacteria

A technology of genetically engineered bacteria and isoleucine, applied in microorganism-based methods, biochemical equipment and methods, bacteria, etc., can solve the problem of backward production technology and production equipment, low acid-producing ability of strains, and inability to meet market demand. and other problems to achieve the effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

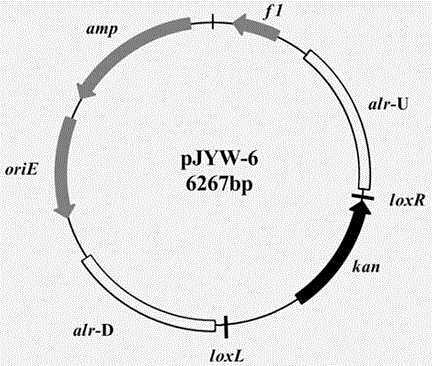

[0030] Example 1 alr Construction of knockout vector pJXW-1

[0031] by C. glutamicum The IWJ001 genome was used as a template, and the Alr -S-(+) / (-) and Alr -X-(+) / (-) are the primers to amplify each 1000bp alr Gene Upstream and Downstream Fragments alr -U, alr -D; based on pDTW-202 (Jinyu Hu, Yanzhen Tan, Yanyan Li, Xiaoqing Hu, Daqing Xu, Xiaoyuan Wang, 2013. Construction and application of an efficient multiple-gene-deletion system in Corynebacterium glutamicum. ) as the template, can -lox-F / R is primer amplification can resistance gene fragments. alr -U starts with xho I. Bam H I digestion, alr -D to Xba I and Pst I digestion, can Fragment ends with Bam H I. Xba I digestion, the three fragments were connected together to xho I and Pst The pBluescript II SK (+) of I digestion, the plasmid that constructs complete is namely alr Knockout vector, named pJXW-1 ( figure 2 ).

Embodiment 2

[0032] Example 2 Construction of expression vector

[0033] First, with the plasmid pDXW-8- FusA - frr for the template, FusA -F, frr -R is the primer, amplification FusA - frr gene fragments, in FusA - frr Introduce at both ends not I and Nhe I restriction site; the PCR product FusA - frr The fragment was digested with the corresponding restriction enzymes and connected into pJYW-4 digested with the same restriction enzymes to complete the construction of the expression plasmid pJYW-4- FusA - frr .

[0034] With the plasmid pDXW-8- ilvBN-ilv A- ppnk (Yin L, Zhao J, Chen C, Hu X, Wang X (2014) Enhancing the carbon flux and NADPH supply to increase L-isoleucine production in Corynebacterium glutamicum .) for the template, wxya -F, ppnk -R is the primer, amplification ilvBN-ilvA-ppnk gene fragments, in ilvBN-ilv A- ppnk Introduce at both ends Sfi I and Asc I restriction site; the PCR product ilvBN-ilv A- ppnk The fragment was digested with c...

Embodiment 3

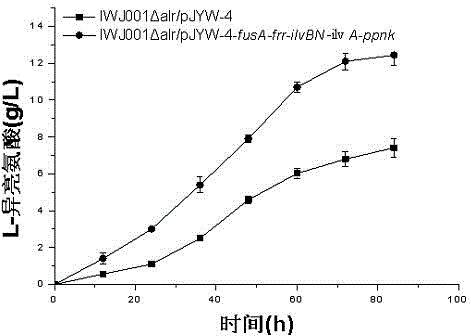

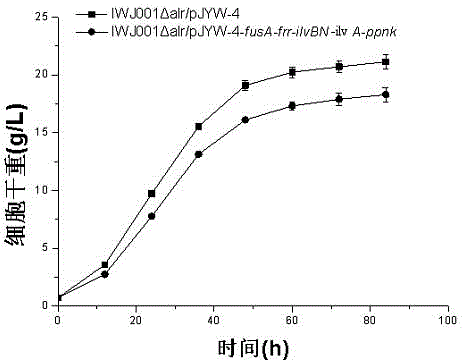

[0036] Embodiment 3 Shake flask fermentation

[0037] From the deposited strain IWJ001Δ alr / pJYW-4- FusA - frr - ilvBN-ilv A- ppnk Streak a ring of bacterial solution in a glycerol tube, streak on the solid-state activation medium, and incubate at 30°C for 36 h. Use an inoculation loop to scrape a ring of bacterial lawn from the activated plate and transfer it to a 250 mL Erlenmeyer flask containing 25 mL of seed medium, and cultivate at 30 °C for 18 h at 200 r / min. Transfer 2.4 mL of bacterial liquid from the cultured seed liquid to a 250 mL Erlenmeyer flask containing 23 mL of fermentation medium, incubate at 30°C for 6 h, and add a final concentration of 1 mM isopropylthiogalactoside (IPTG) Protein expression was induced until the end of fermentation (t=72h).

[0038] step time %A %B 1 0 92 8 2 27 40 60 3 31.5 0 100 4 32 0 100 5 34 0 100 6 35.5 92 8

[0039] Medium used in this experiment:

[0040] Activ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com