Lateral steam discharge electromagnetic pressure relief valve structure for electric station main steam system

A technology of main steam system and pressure relief valve, which is applied in the direction of valve shell structure, lifting valve, balance valve, etc., to achieve the effect of ensuring manufacturing quality, strong elastic compensation ability, and good structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

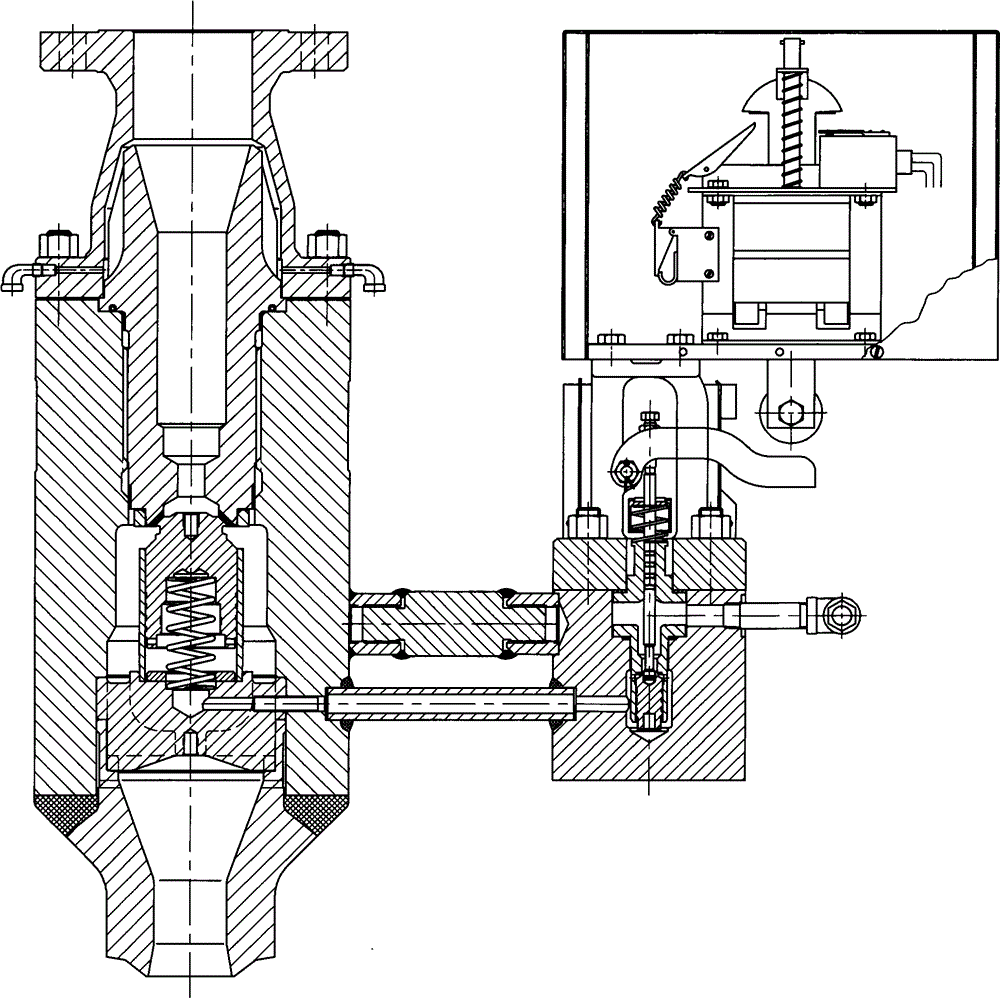

[0042] like Figure 5 and Figure 6 Shown is a schematic diagram of the product structure of the electromagnetic pressure relief valve of this embodiment. The electromagnetic pressure relief valve is used for supporting the main steam system of a 300MW subcritical unit, and the valve body is processed by WC9 casting.

[0043] The electromagnetic pressure relief valve adopts the integrated structural design of main valve and auxiliary valve. The pilot sealing structure of the auxiliary valve is arranged on the upper side of the main valve disc. The opening of the valve is driven by the driving device (17) driven by an electromagnet. The direction of the valve sealing surface is downward, the valve body (1) has a double exhaust structure with exhaust flanges (1-5) on both left and right sides, and the flow channel of the valve body is designed as: the inlet channel from the lower side The hole (1-1) goes upwards, bypasses the medium outlet channel hole on the lower side of the ...

Embodiment 2

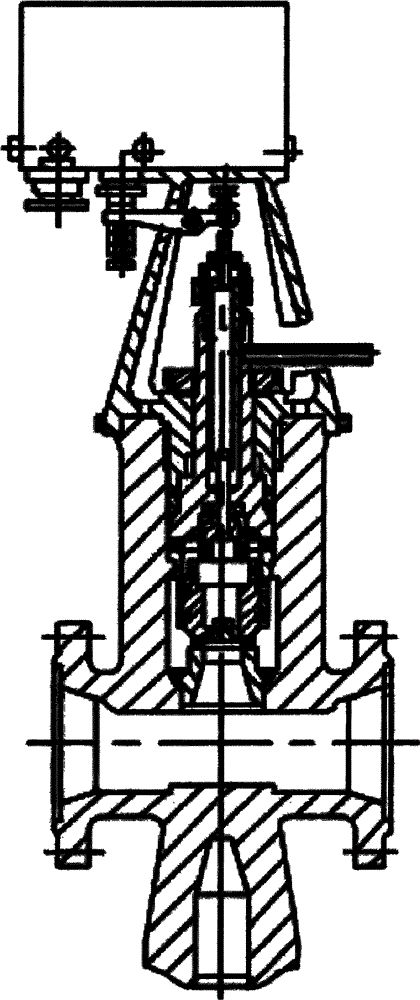

[0068] like Figure 13 Shown is a schematic diagram of the product structure of the electromagnetic pressure relief valve of this embodiment. The electromagnetic pressure relief valve is used for supporting the main steam system of a 1000MW ultra-supercritical thermal power unit, and the material of the valve body is F92 forged steel. The driving device (17) configured on the upper part of the valve can be a driving device provided by an electromagnet, or a driving device controlled by a solenoid valve to control a pneumatic mechanism to provide an active force; when the valve exhausts steam, the driving device (17) passes through The push rod on the lower side drives the valve stem (9) to open the valve.

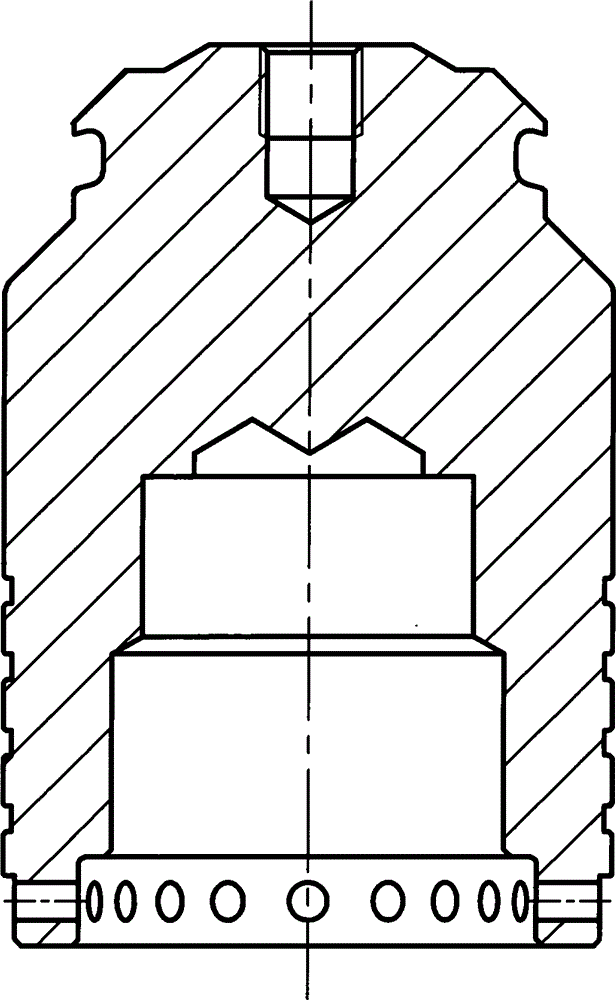

[0069] The technical scheme of the valve structure of the electromagnetic pressure relief valve of this embodiment, only the specific implementation structure adopted by the valve body (1) is different from that of Embodiment 1. The valve body (1) of this embodiment adopts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com