A method for producing Flammulina velutipes mycelium by utilizing ginkgo biloba residue

A technology of ginkgo biloba slag and Flammulina velutipes is applied in the fields of botanical equipment and methods, fertilizers made from biological waste, applications, etc. Improve the utilization rate of biotransformation, protect the environment, and improve the effect of memory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for producing enoki mushroom mycelium extracted from enoki mushroom polysaccharides by using ginkgo leaf residue produced by an upstream enterprise as the main raw material component, characterized in that it comprises the following steps:

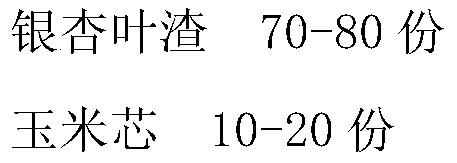

[0026] Step 1, weighing, take ginkgo biloba residue, corn cob, bran, white sugar, gypsum according to the formula, and its mass ratio is:

[0027]

[0028]

[0029] Step 2, base material pretreatment, first crush the ginkgo leaf residue weighed in step 1 into a size of 0.3-0.5cm, add corncobs and cellulase precursors in proportion to mix, and mix the cellulase precursors with the crushed ginkgo leaves The mass ratio of slag and corncob mixture is 1:5, adjust the dry humidity with water to control the water content at 40-50%, adjust the pH to 4.5-5.5 with acetic acid, mix well and put it in the cement pool for smoothing, Keep the material plane 20-30cm lower than the pool mouth, cover with plastic film, leave ventilati...

Embodiment 2

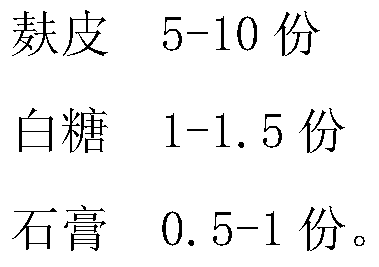

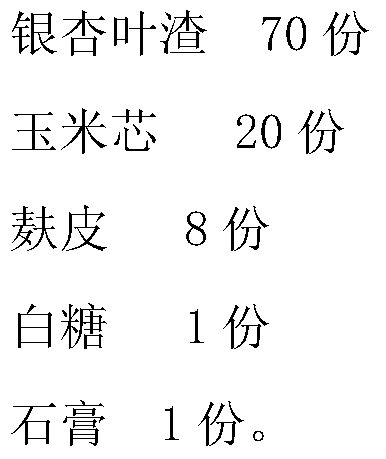

[0037] Step 1, weighing, take ginkgo biloba residue, corn cob, bran, white sugar, gypsum according to the formula, and its mass ratio is:

[0038]

[0039] Step 2, base material pretreatment, first crush the ginkgo leaf residue weighed in step 1 into a size of 0.3-0.5cm, add corncobs and cellulase precursors in proportion to mix, and mix the cellulase precursors with the crushed ginkgo leaves The mass ratio of slag and corncob mixture is 1:4. Adjust the dry humidity with water to control the water content at 50%, adjust the pH to 4.5-5.5 with acetic acid, mix well, put it into the cement pool and smooth it with light pressure, keep the material level 20-30cm below the pool mouth, cover with plastic film, Vents are left at the four corners of the cement pool, and the temperature in the pool is controlled at 40-50°C. After 5 days of fermentation and degradation, the degraded base material is taken out; generally, the degraded base material treated with cellulase parent matter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com