Sulfur-free crisp pear slices and preparation method thereof

A technology of pear slices and crisp slices, which is applied in food preparation, multi-step food processing, climate change adaptation, etc., can solve the problems of nutrient loss and slow drying rate, and achieve less nutrient loss, convenient operation, and crisp taste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1, the preparation of sulfur-free pear chips

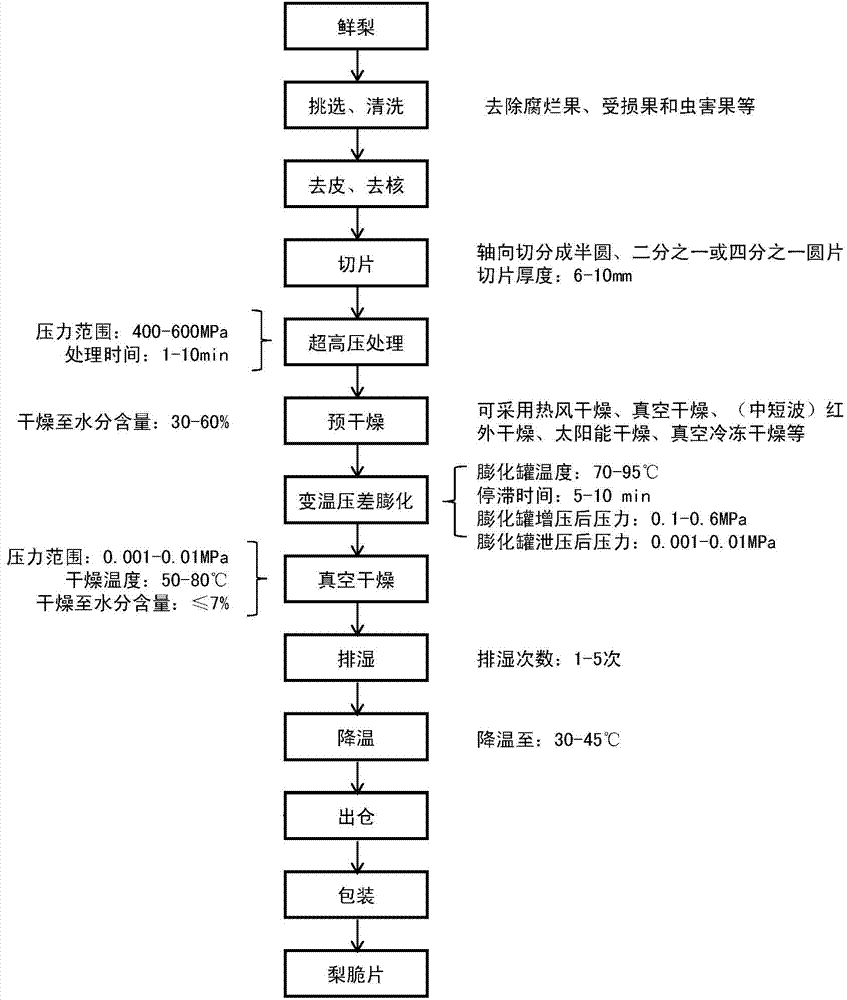

[0052] The schematic flow sheet of preparation method of the present invention is as figure 1 shown.

[0053] 1. Preparation of sulfur-free pear chips

[0054] (1) Pretreatment of pears:

[0055] 1) Fruit selection and cleaning: select nine-ripe Fengshui pears, remove damaged, deformed and pest-infested fruits, and then clean them;

[0056] 2) Peeling and core removal: manually or mechanically remove the skin and core from the pears cleaned in step (1);

[0057] 3) Slicing: the pear pulp after the peeling and pitting in step (2) is axially cut into 1 / 4 round slices with a thickness of 6 mm through a slicer to obtain sliced pears.

[0058] (2) Ultra-high pressure treatment: The pear slices obtained in step (1) were subjected to ultra-high pressure treatment at a pressure of 500 MPa and a temperature of 25° C., and the processed pear slices were obtained after treatment for 5 minutes.

[0059] (3) Pre-drying...

Embodiment 2

[0108] Embodiment 2, the preparation of sulfur-free pear chips

[0109] The preparation method of sulfur-free pear chips in the present embodiment is the same as the step in Example 1, except that:

[0110] The slice thickness of pear slice is 7mm in the step (1);

[0111] The pressure of the ultra-high pressure treatment in the step (2) is 550MPa, and the treatment time is 2.5min;

[0112] The pre-drying in step (3) adopts vacuum drying, the drying temperature is 65° C., the vacuum degree is 0.004 MPa, the time is 60 min, and the pre-drying is carried out until the mass moisture content is 45%;

[0113] In the step (4), the variable temperature and pressure difference puffing and drying, the temperature in the puffing tank is 90°C, and the high-pressure gas is not filled, and the step (4) is repeated 3 times;

[0114] The vacuum drying pressure in step (5) is 0.002MPa, and the number of times of dehumidification is 3 times.

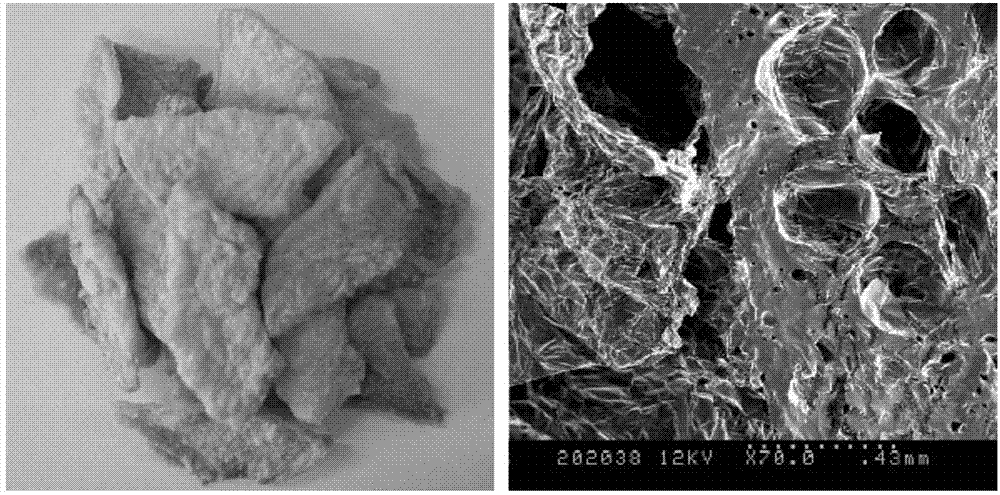

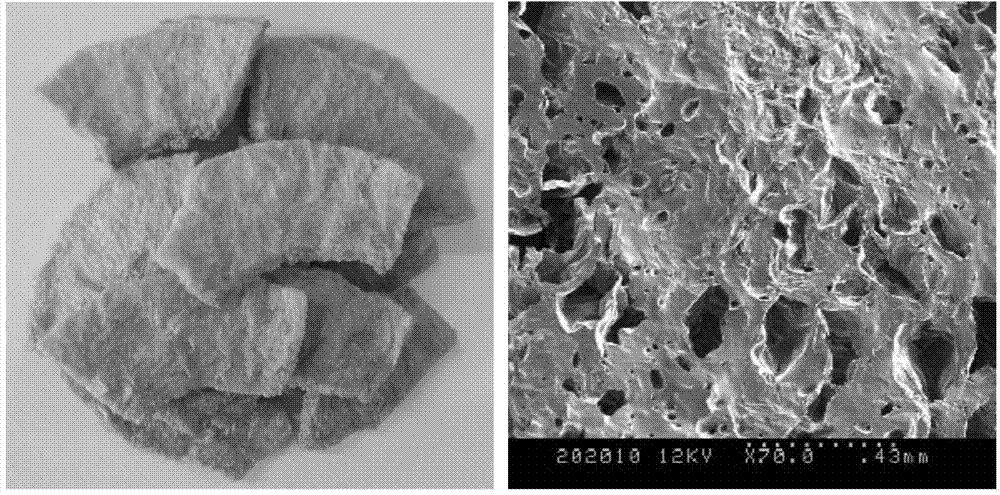

[0115] Such as Figure 5 Shown is the appearan...

Embodiment 3

[0118] Embodiment 3, the preparation of pear chips without sulfur

[0119] The preparation method of sulfur-free pear chips in the present embodiment is the same as the step in Example 1, except that:

[0120] The pressure of ultra-high pressure treatment in step (2) is 400MPa, and the treatment time is 6min;

[0121] The pre-drying in step (3) adopts medium and short-wave infrared drying, the drying temperature is 65 ° C, the time is 40 min, and the pre-drying is until the mass moisture content is 35%;

[0122] In step (4), the temperature and pressure difference are expanded and dried, and the temperature in the expanded tank is 90°C. Fill the expansion tank with high-pressure air to increase the pressure of the expansion tank to 0.2MPa. Expanding and drying repeated operation 2 times;

[0123] Step (5) The pressure of vacuum drying is 0.002MPa, and the number of dehumidification is 3 times;

[0124] The packaging in the step (6) post-processing adopts polyethylene packa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com