A kind of method that contains tungsten, vanadium, arsenic catalyst to remove arsenic

A catalyst and arsenic removal technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of activity reduction, achieve simple process, reduce cost, The effect of not polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

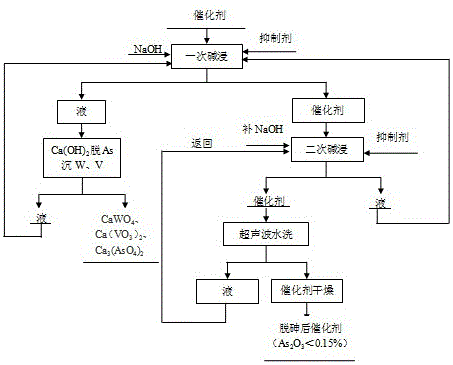

[0015] Embodiment 1, As in the arsenic-containing catalyst 2 o 3 The content is 3 to 4%. Firstly, the catalyst containing tungsten, vanadium and arsenic, and the sodium hydroxide solution with a concentration of 3g / l are placed in an ultrasonic reactor for alkaline leaching and arsenic removal. m 3 / h, ultrasonic power 500w. During the reaction, the added inhibitor EDTA and ammonium bicarbonate were 3 g / l. After the reaction, liquid-solid separation is carried out, and the liquid phase is subjected to Ca(OH) 2 After the arsenic removal treatment, the obtained solution can be reused in the whole system, and the obtained slag is CaWO 4 , Ca (VO 3 ) 2 , Ca 3 (AsO 4 ) 2 Can be stacked directly.

[0016] After one alkaline leaching, the catalyst is subjected to secondary alkaline leaching. In the process, 1g / l sodium hydroxide solution, 1g / l inhibitor EDTA and 1g / l ammonium bicarbonate are added, which are also carried out in an ultrasonic reactor and controlled. The re...

Embodiment 2

[0018] Embodiment 2, As in the arsenic-containing catalyst 2 o 3 The content is 3 to 4%. Firstly, the catalyst containing tungsten, vanadium and arsenic, and the sodium hydroxide solution with a concentration of 5g / l are placed in an ultrasonic reactor for alkaline leaching and arsenic removal. 1.2m 3 / h, ultrasonic power 500w. During the reaction, 3 g / l of inhibitor EDTA and 4 g / l of ammonium bicarbonate were added. After the reaction, liquid-solid separation is carried out, and the liquid phase is subjected to Ca(OH) 2 After the arsenic removal treatment, the obtained solution can be reused in the whole system, and the obtained slag is CaWO 4 , Ca (VO 3 ) 2 , Ca 3 (AsO 4 ) 2 Can be stacked directly.

[0019] The catalyst after one alkali leaching is subjected to a second alkali leaching, during which 2g / l sodium hydroxide solution and inhibitor 1g / l EDTA and 1g / l ammonium bicarbonate are added, also carried out in an ultrasonic reactor, controlled The reaction te...

Embodiment 3

[0021] Embodiment 3, As in the arsenic-containing catalyst 2 o 3 The content is 3 to 4%. Firstly, the catalyst containing tungsten, vanadium and arsenic, and the sodium hydroxide solution with a concentration of 7g / l are placed in an ultrasonic reactor for alkaline leaching and arsenic removal. 1.2m 3 / h, ultrasonic power 700w. During the reaction, 4 g / l of inhibitor EDTA and 4 g / l of ammonium bicarbonate were added. After the reaction, liquid-solid separation is carried out, and the liquid phase is subjected to Ca(OH) 2 After the arsenic removal treatment, the obtained solution can be reused in the whole system, and the obtained slag is CaWO 4 , Ca (VO 3 ) 2 , Ca 3 (AsO 4 ) 2 Can be stacked directly.

[0022] The catalyst after one alkaline leaching is subjected to secondary alkaline leaching, during which 2g / l sodium hydroxide solution and inhibitor 2g / l EDTA and 2g / l ammonium bicarbonate are added, also carried out in an ultrasonic reactor, controlled Reaction t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com