Copper doped cerium oxide photocatalyst and preparation method thereof

A technology of ceria and photocatalyst, which is applied in the field of nanotechnology, can solve the problems of high cost, cumbersome preparation methods, and difficulty in industrial production of catalysts, and achieve improved photodegradation ability, improved catalytic effect, and changed photocatalytic activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

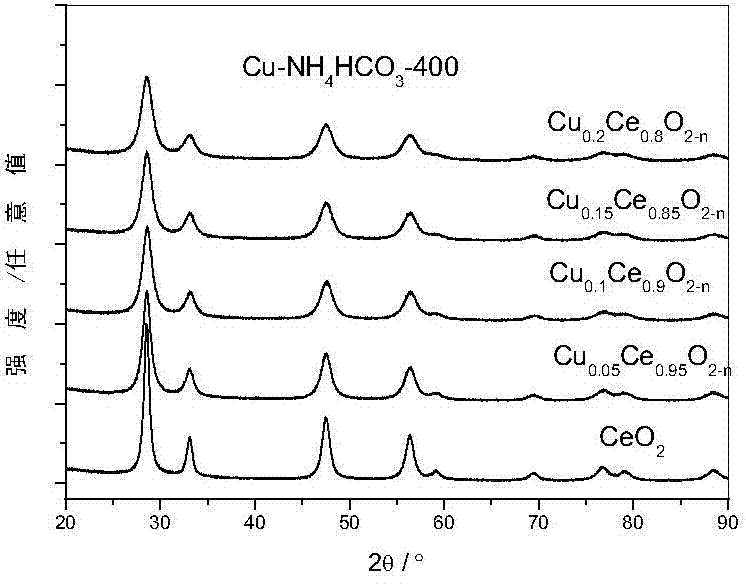

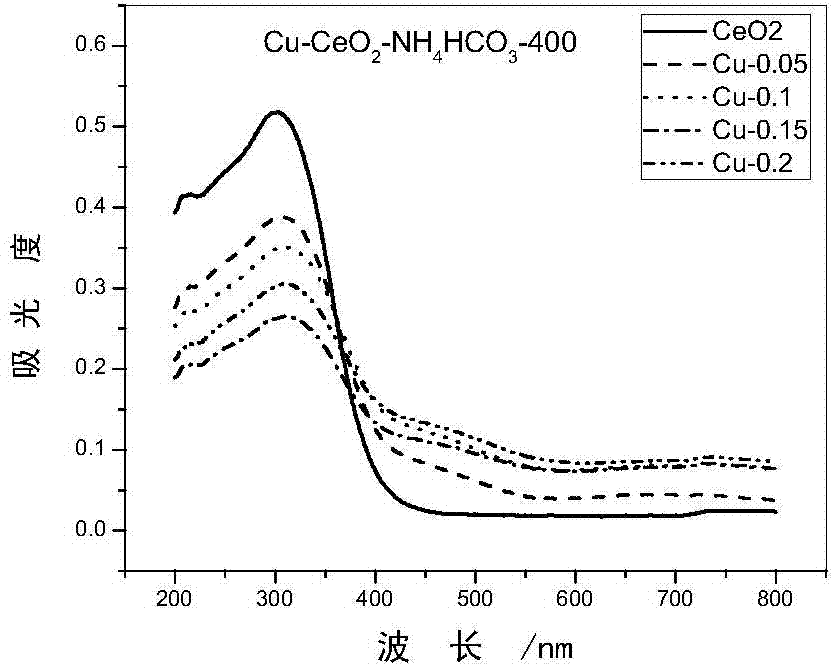

[0082] A non-copper-doped ceria photocatalyst with the formula Cu x Ce 1-x o 2-x , where x is 0.

[0083] The preparation method of the above-mentioned ceria photocatalyst without copper doping specifically comprises the following steps:

[0084] (1) At room temperature, use deionized water to prepare an aqueous solution of cerium nitrate with a concentration of 0.1mol / L and an aqueous solution of ammonium bicarbonate with a concentration of 0.5mol / L;

[0085] (2) Add 100 mL of cerium nitrate aqueous solution with a concentration of 0.1 mol / L dropwise at a rate of 2.5 mL / min to 120 ml of an aqueous ammonium bicarbonate solution with a concentration of 0.5 mol / L at a temperature of 80°C, and carry out co-production at 800 rpm. Precipitation reaction for 30 minutes, then naturally cooled to room temperature, the obtained reaction liquid was centrifuged at 8000 rpm for 5-15 minutes, the obtained precipitate was washed with deionized water until the effluent was neutral, then t...

Embodiment 2

[0093] A copper-doped ceria photocatalyst with the formula Cu x Ce 1-x o 2-x , where x is 0.05.

[0094] Above-mentioned a kind of copper-doped ceria photocatalyst, specifically comprises the following steps:

[0095] (1) At room temperature, use deionized water to prepare an aqueous solution of cerium nitrate with a concentration of 0.1mol / L, an aqueous solution of copper nitrate with a concentration of 0.1mol / L, and an aqueous solution of ammonium bicarbonate with a concentration of 0.5mol / L;

[0096] (2) Take 5 mL of copper nitrate aqueous solution and 95 mL of cerium nitrate aqueous solution and ultrasonically mix them to obtain a mixed solution of copper and cerium;

[0097] In the copper and cerium mixed solution, the molar ratio of copper: cerium is 0.05:0.95;

[0098] (3) Add the copper and cerium mixed solution obtained in step (2) dropwise at a controlled rate of 2.5 mL / min to 120 ml of ammonium bicarbonate aqueous solution with a concentration of 0.5 mol / L at a ...

Embodiment 3

[0106] A copper-doped ceria photocatalyst with the formula Cu x Ce 1-x o 2-x , where x is 0.1.

[0107] Above-mentioned a kind of copper-doped ceria photocatalyst specifically comprises the following steps:

[0108](1) At room temperature, use deionized water to prepare an aqueous solution of cerium nitrate with a concentration of 0.1mol / L, an aqueous solution of copper nitrate with a concentration of 0.1mol / L, and an aqueous solution of ammonium bicarbonate with a concentration of 0.5mol / L;

[0109] (2) Take 10 mL of copper nitrate aqueous solution and 90 mL of cerium nitrate aqueous solution and ultrasonically mix them to obtain a mixed solution of copper and cerium;

[0110] In the copper and cerium mixed solution, the molar ratio of copper: cerium is 0.1:0.9;

[0111] (3) Add the copper and cerium mixed solution obtained in step (2) dropwise at a controlled rate of 2.5 mL / min to 120 ml of ammonium bicarbonate aqueous solution with a concentration of 0.5 mol / L at a temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com