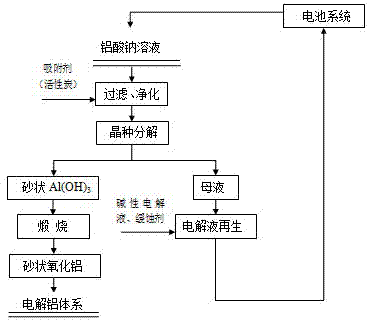

Recycling process of sodium aluminate solution in aluminum-air battery preparation process

An air battery and preparation process technology, which is applied in the preparation of alumina/hydroxide, alkali metal aluminate/alumina/aluminum hydroxide, etc., can solve problems such as aluminum overcapacity and the downturn in the electrolytic aluminum industry, and achieve The technological process is simple, the cost is reduced, and the effect of resource recycling is realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] (2) The sand-like aluminum hydroxide obtained by decomposing the seed crystals is transformed into sand-like alumina at a high temperature of 1100°C at a calcination temperature, and enters the electrolytic aluminum system.

[0015] (3) After the purified mother liquor is added with a certain amount of alkaline electrolyte and corrosion inhibitor, it can be used as a fresh electrolyte and reused in the battery system to realize the recycling of waste electrolyte sodium aluminate solution.

[0016] Example 2

Embodiment 2

[0018] (2) The sand-like aluminum hydroxide obtained by decomposing the seed crystals is transformed into sand-like alumina at a high temperature of 1100°C at a calcination temperature, and enters the electrolytic aluminum system.

[0019] (3) After the purified mother liquor is added with a certain amount of alkaline electrolyte and corrosion inhibitor, it can be used as a fresh electrolyte and reused in the battery system to realize the recycling of waste electrolyte sodium aluminate solution.

[0020] Example 3

Embodiment 3

[0022] (2) The sand-like aluminum hydroxide obtained by decomposing the seed crystals is transformed into sand-like alumina at a high temperature of 1200°C and enters the electrolytic aluminum system.

[0023] (3) After the purified mother liquor is added with a certain amount of alkaline electrolyte and corrosion inhibitor, it can be used as a fresh electrolyte and reused in the battery system to realize the recycling of waste electrolyte sodium aluminate solution.

[0024] Example 4

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com