Viscosity reduction reaction device for high-concentration polyacrylamide in sewage of oilfield and viscosity reduction method

A technology of polyacrylamide and oilfield sewage, applied in water/sewage treatment, chemical instruments and methods, light water/sewage treatment, etc., can solve the problem of increased viscosity of oil well production fluid, low concentration of polyacrylamide, and low viscosity reduction rate To achieve obvious environmental benefits, reasonable device design, and heat reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

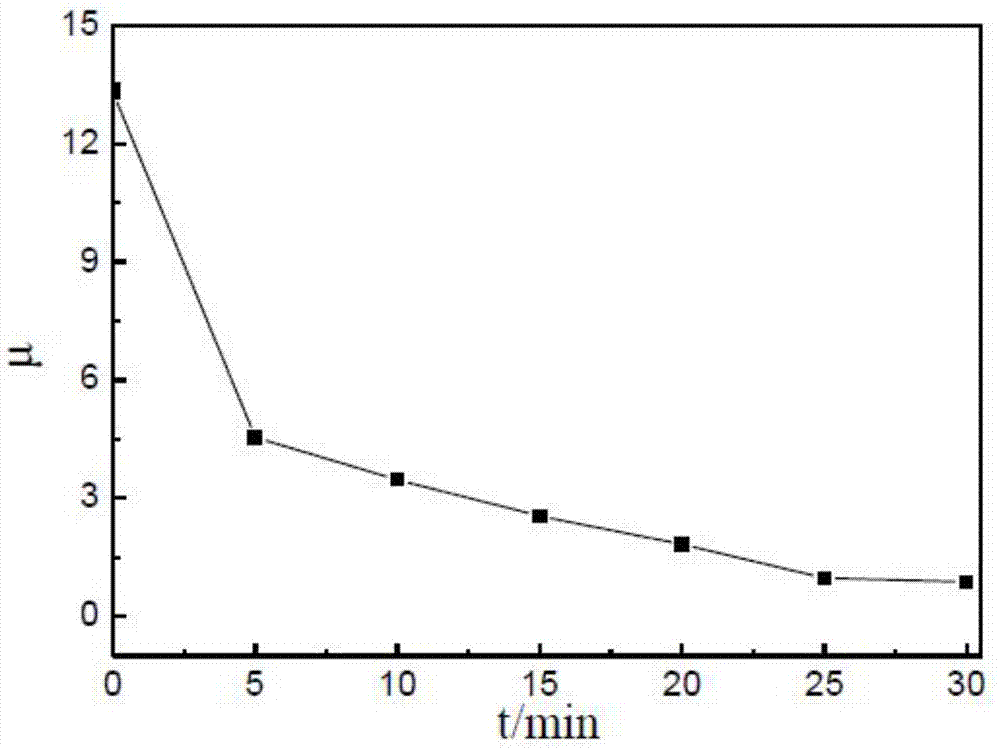

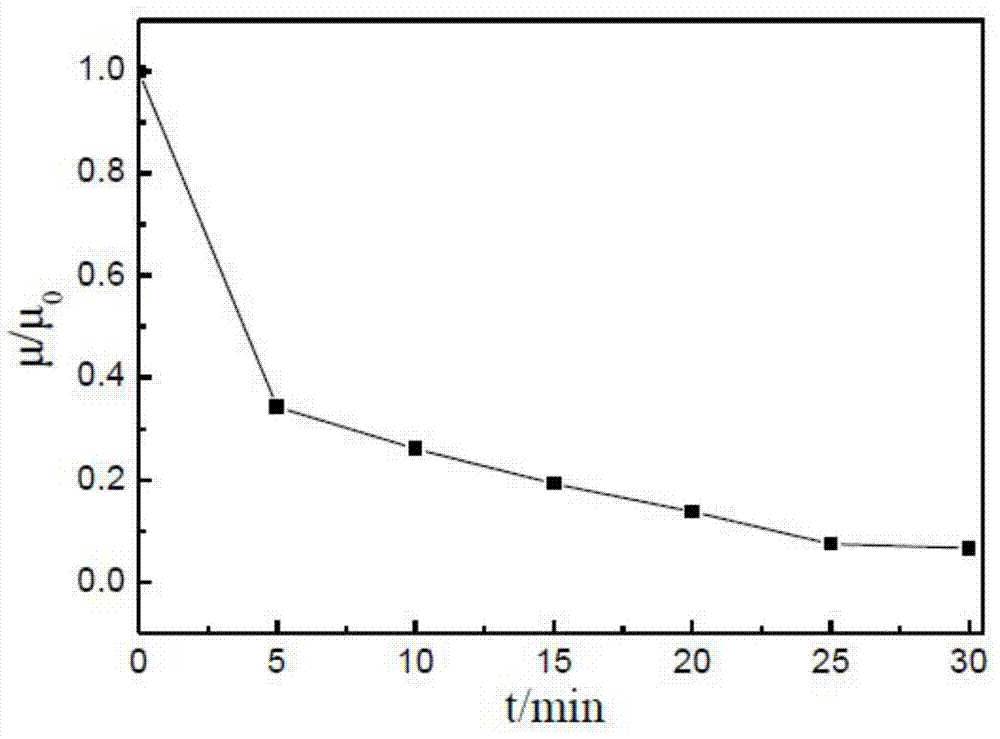

[0037] Prepare 100 mL of 100 mg / L polyacrylamide aqueous solution and transfer it to a quartz reactor. Turn on the high-pressure mercury light for 30 minutes, take samples every 5 minutes, measure the viscosity of the solution with a rotational viscometer, and draw the change curve of viscosity and viscosity reduction rate with time. μ is the viscosity of polyacrylamide after degradation (its unit is centipoise, cP), μ 0 is the initial viscosity of polyacrylamide. After 10 minutes of reaction, the viscosity of the solution decreased significantly, and the viscosity reduction rate reached 74%; after 30 minutes of reaction, the viscosity reduction rate reached 93.4%, and the solution viscosity was the same as that of distilled water (0.88cP). Viscosity reduction effect such as figure 1 , figure 2 shown.

Embodiment 2

[0039] Prepare 100 mL of 200 mg / L polyacrylamide aqueous solution and transfer it to a quartz reactor. Turn on the high-pressure mercury light for 30 minutes, take samples every 5 minutes, measure the viscosity of the solution with a rotational viscometer, and draw the change curve of viscosity and viscosity reduction rate with time. μ is the viscosity of polyacrylamide after degradation, μ 0 is the initial viscosity of polyacrylamide. After 10 minutes of reaction, the viscosity reduction rate reached 91.6%; after 30 minutes of reaction, the viscosity reduction rate reached 95.9%, and the solution viscosity decreased to the same viscosity as distilled water 0.88cP. Viscosity reduction effect such as image 3 , Figure 4 shown.

Embodiment 3

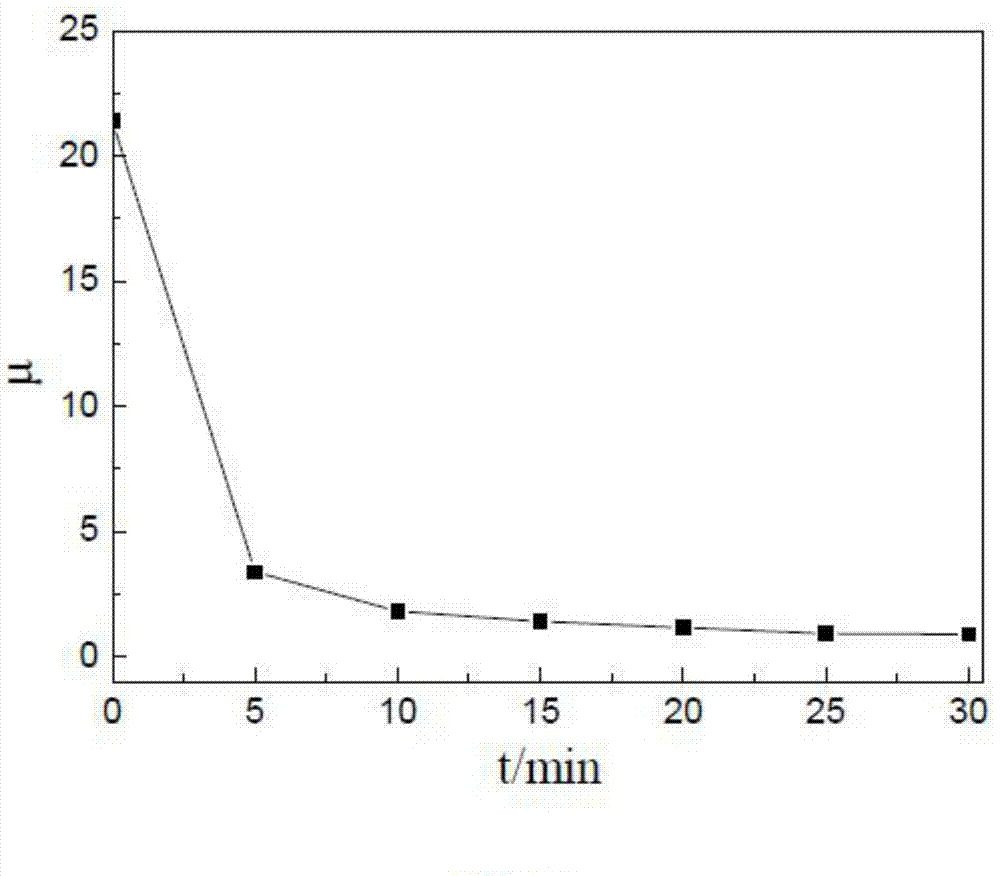

[0041]Prepare 100 mL of 400 mg / L polyacrylamide aqueous solution and transfer it to a quartz reactor. Turn on the high-pressure mercury light for 30 minutes, take samples every 5 minutes, measure the viscosity of the solution with a rotational viscometer, and draw the change curve of viscosity and viscosity reduction rate with time. μ is the viscosity of polyacrylamide after degradation, μ 0 is the initial viscosity of polyacrylamide. After 10 minutes of reaction, the viscosity reduction rate reached 88.8%; after 30 minutes of reaction, the viscosity reduction rate reached 97.8%, and the solution viscosity dropped to 0.89cP, which was very similar to the viscosity of distilled water (0.88cP). Viscosity reduction effect such as Figure 5 , Image 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com