Rock wool and method for producing rock wool by utilization of high-alkali red mud

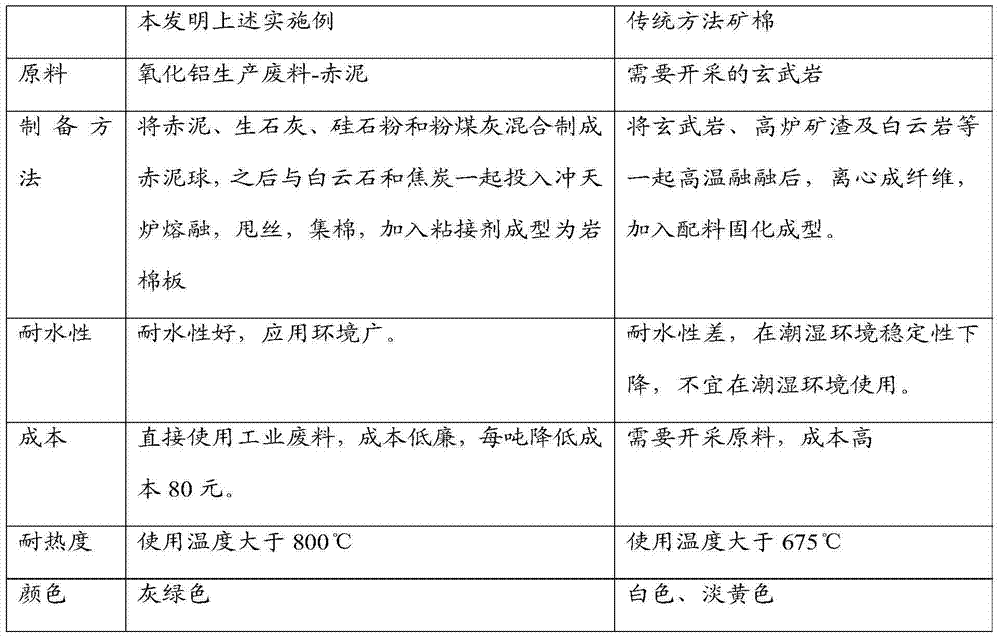

A technology of red mud and high alkali, which is applied in the field of rock wool processing, can solve the problems of high production cost of rock wool, potential safety hazards, and environmental impact, and achieve the effects of eliminating potential safety hazards, overcoming the decline in stability, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The red mud, quicklime, silica powder and fly ash with a humidity of 5% are fully mixed in a mass ratio of 45:8:25:8, wherein the acidity coefficient of the mixture of red mud, quicklime, silica powder and fly ash (SiO 2 、Al 2 o 3) / (CaO, MgO) greater than 1.6, while SiO 2 / Al 2 o 3 Greater than 2, CaO / MgO greater than 1. After stirring evenly, use a ball press to press into red mud balls with a diameter of 7-8cm.

[0038] The pressed red mud balls are dried and mixed with massive dolomite and coke, put into the cupola and melted at 1460°C, then use a centrifuge to form fibers, and apply a binder to produce flocculent mineral wool. Then it is made into rock wool products by heat, pressure, curing and cutting.

Embodiment 2

[0040] The red mud, quicklime, silica powder and fly ash with a humidity of 8% are fully mixed at a mass ratio of 60:12:35:14, wherein the acidity coefficient of the mixture of red mud, quicklime, silica powder and fly ash (SiO 2 、Al 2 o 3 ) / (CaO, MgO) greater than 1.6, while SiO 2 / Al 2 o 3 Greater than 2, CaO / MgO greater than 1. After stirring evenly, use a ball press to press into red mud balls with a diameter of 8-9cm.

[0041] The pressed red mud balls are dried and mixed with massive dolomite and coke, put into the cupola and melted at 1450°C, then use a centrifuge to form fibers, and apply a binder to produce flocculent mineral wool. Then it is made into rock wool products by heat, pressure, curing and cutting.

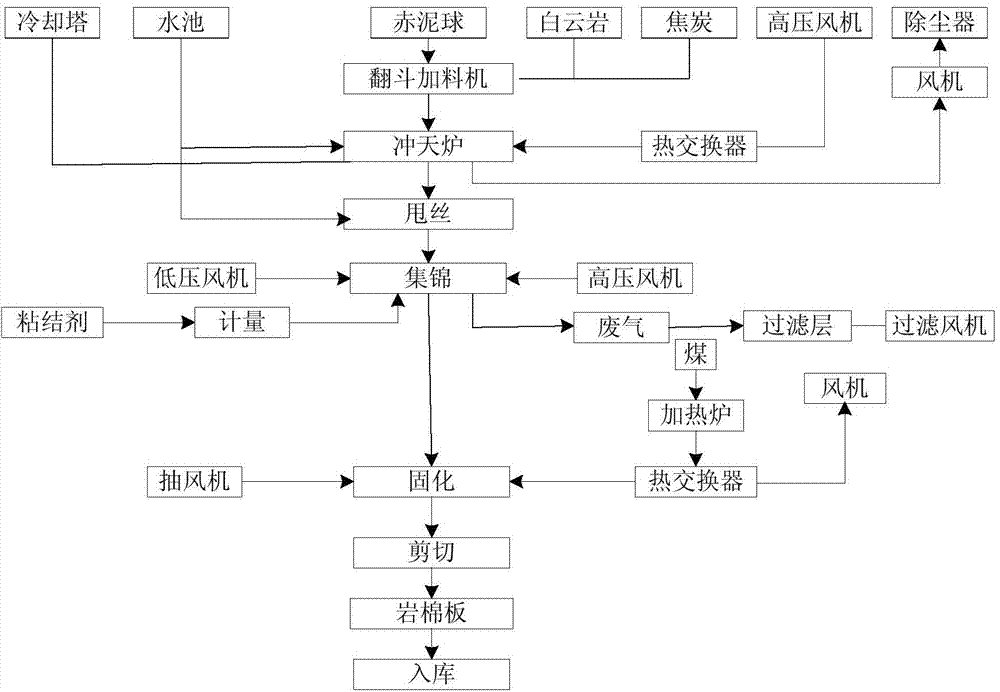

[0042] like figure 1 As shown, put red mud balls, dolomite, and coke into the tipping bucket feeder, and feed them into the cupola through the tipping bucket feeder. The cupola is equipped with cooling towers, water pools, heat exchangers, and high-press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com