Low-velocity liquid silicon rubber and preparation method thereof

A liquid silicone rubber, low-viscosity technology, applied in the field of rubber, can solve the problems of increased viscosity of liquid silicone rubber, low strength of liquid silicone rubber, affecting film formation and processing, etc., to achieve low viscosity, strong fluidity and processability , The effect of convenient potting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A low-viscosity liquid silicone rubber, which is composed of A component and B component in a weight ratio or volume ratio of 1:1, wherein,

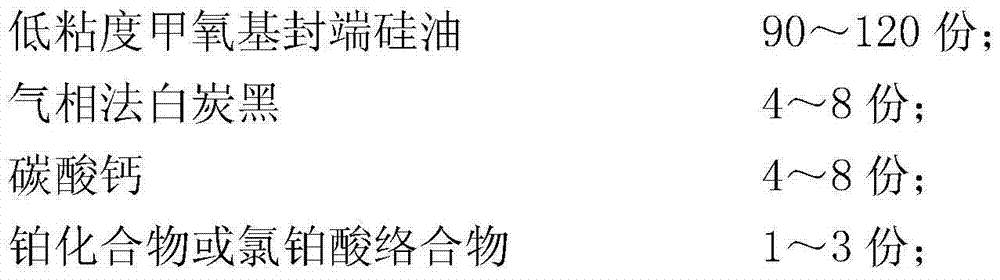

[0027] In parts by weight, component A includes:

[0028]

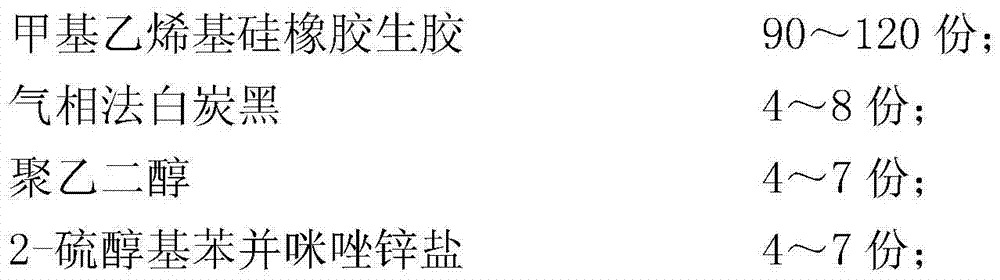

[0029] In parts by weight, component B includes:

[0030]

[0031] Among them, fumed silica and calcium carbonate in component A are used as reinforcing agents to improve the tear resistance, heat resistance, and aging resistance of silicone rubber products.

[0032] The platinum compound or chloroplatinic acid complex in component A acts as a catalyst, and the vinyl group in the vinyl-containing polydiorganosiloxane and the silicon-hydrogen bond in the crosslinking agent undergo silicon hydrogenation under the action of a platinum-based catalyst Addition reaction, so that the linear base polymer is cross-linked into a three-dimensional network structure under the action of a cross-linking agent to become an elastomer. In this embodiment, a chloroplatinic acid com...

Embodiment 2

[0047] A low-viscosity liquid silicone rubber, which is composed of A component and B component in a weight ratio or volume ratio of 1:1, wherein,

[0048] In parts by weight, component A includes:

[0049]

[0050] In parts by weight, component B includes:

[0051]

[0052] Among them, the platinum compound or chloroplatinic acid complex in component A is used as a catalyst, and the vinyl group in the vinyl-containing polydiorganosiloxane and the silicon-hydrogen bond in the crosslinking agent occur under the action of the platinum series catalyst Hydrosilylation reaction, so that the linear base polymer is cross-linked into a three-dimensional network structure under the action of a cross-linking agent to become an elastomer. In this embodiment, a platinum compound is selected as the catalyst, specifically platinum dioxide.

[0053] Inhibitors for component B are acetylenic alcohols.

[0054] The preparation method of A component, it comprises the steps:

[0055] 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com