Low stress thermally conductive silicone gel composition

A technology of gel composition and thermal conductive silicon, which is applied in the directions of adhesives, adhesive additives, polymer adhesive additives, etc. Attachment and other problems, to achieve good operability, improve heat dissipation efficiency, and facilitate potting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

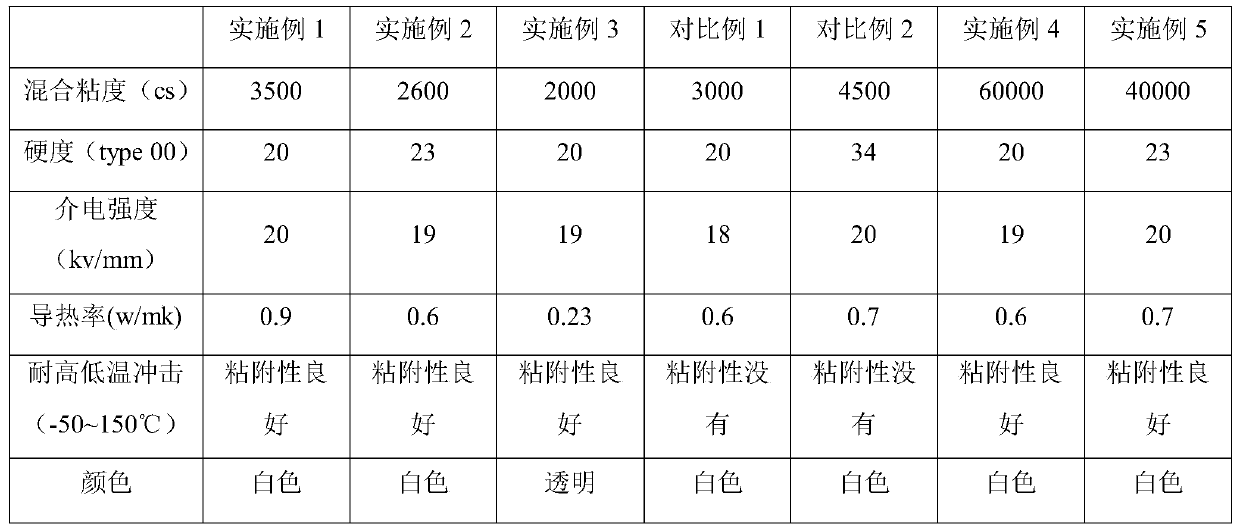

Examples

Embodiment 1

[0038] 100 parts vinyl-terminated polydimethylsiloxane, 60 parts aluminum hydroxide, 100 parts aluminum oxide, 5 parts graphene, 3 parts hexamethyldisilazane, 0.5 parts purified water, add to planetary power mixer and mix After 1 hour, the temperature was raised to 150° C., and the mixture was stirred and lowered for 2 hours, and 1 part of chloroplatinic acid-divinyltetramethyldisiloxane catalyst was dispersed uniformly to prepare component A.

[0039] 100 parts of vinyl terminated polydimethylsiloxane, 60 parts of aluminum hydroxide, 80 parts of aluminum oxide, 20 parts of silicon micropowder, 5 parts of graphene, 3 parts of hexamethyldisiloxane, 0.5 parts of purified water, add Mix in a planetary power mixer for 1 hour, raise the temperature to 150°C, stir and de-low for 2 hours, stir with 1 part of crosslinking agent (synthesis 1 of hydrogen-containing branched chain siloxane), 3 parts of extender, and 1.2 parts of acetylene cyclohexanol Disperse uniformly to prepare B comp...

Embodiment 2

[0043] 100 parts vinyl terminated polydimethyl-methyl vinyl siloxane, 60 parts aluminum hydroxide, 30 parts alumina, 60 parts silicon micropowder, 2.4 parts hexamethyldisilazane, 0.5 parts water added to Planetary Power In a mixer, stir at room temperature for 1 hour, stir at 150° C. for 2 hours, add 1 part of chloroplatinic acid-divinyltetramethyldisiloxane catalyst and disperse it uniformly to prepare component A.

[0044] 100 parts of vinyl-terminated polydimethyl-methyl vinyl siloxane, 60 parts of aluminum hydroxide, 30 parts of alumina, 60 parts of silicon micropowder, 2.4 parts of hexamethyldisilazane, 0.5 parts of purified water, add In a planetary power mixer, stirring at room temperature for 1 hour, stirring at 150 ° C for 2 hours, 1.2 parts of acetylene cyclohexanol, 2 parts of cross-linking agent (synthesis of hydrogen-containing branched siloxane 3), 5 parts of extender , stir and disperse uniformly to prepare B component.

[0045] Finally, the A component and the...

Embodiment 3

[0048] 95 parts of vinyl-terminated polydimethylsiloxane, 5 parts of polydimethyl-methyl vinyl siloxane containing vinyl on the side, and 10 parts of silicone resin powder, add them to a planetary power mixer, heat up and stir at 120°C After 2 hours of lowering, 1 part of chloroplatinic acid-divinyltetramethyldisiloxane catalyst was added and dispersed uniformly to prepare component A.

[0049]95 parts of vinyl-terminated polydimethylsiloxane, 5 parts of polydimethyl-methyl vinyl siloxane containing vinyl on the side, and 10 parts of silicone resin powder, add them to a planetary power mixer, heat up and stir at 120°C Take off for 2 hours, add 1 part of acetylene cyclohexanol, 1 part of crosslinking agent (synthesis 1 of hydrogen-containing branched chain siloxane), 6 parts of extender, stir and disperse evenly to prepare B component.

[0050] Finally, the A component and the B component are mixed and stirred uniformly according to the mass ratio of 1:1, and the low-stress the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com