Epoxy elastic putty for surface of concrete

A concrete surface, elastic putty technology, applied in the direction of filling slurry, etc., can solve the problems of cracks in the putty layer, poor adhesion between layers, insufficient flexibility, etc., to reduce the curing crosslinking density, easy to scrape, Excellent adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1 prepares epoxy elastic putty

[0019] (1) A component

[0020] ① See Table 1 for the formula of component A.

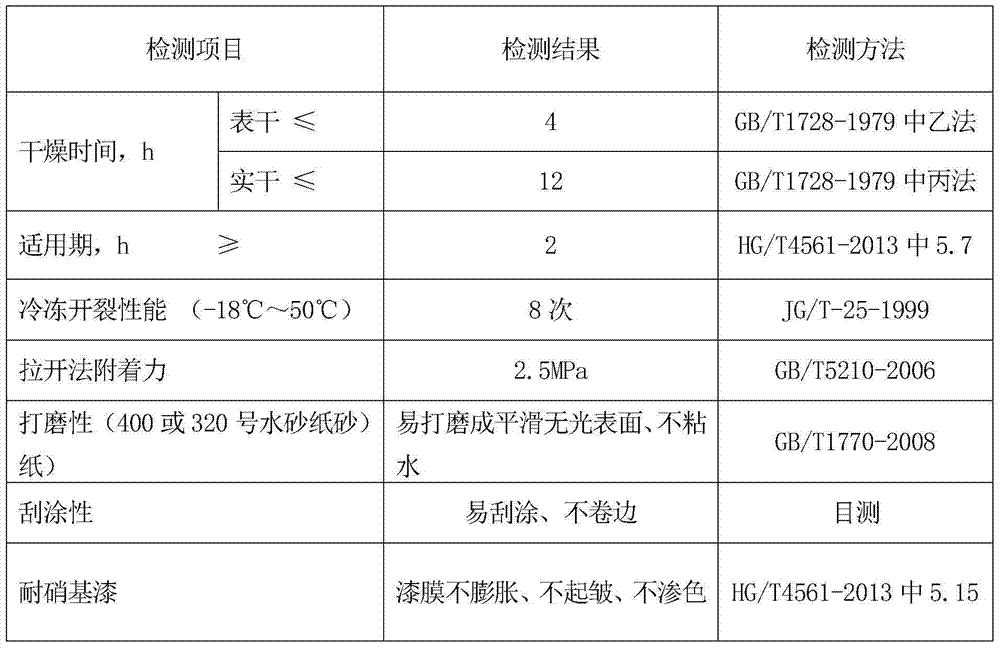

[0021] Table 1

[0022]

[0023] In the table: NPEL-128 is a product of Nanya Epoxy Resin Co., Ltd.; YDF-172 is a product of Guodu Chemical (Kunshan) Co., Ltd.; TLA-100 is a product of Tianlun Chemical Co., Ltd.

[0024] ② Preparation of component A

[0025] In the container, first add liquid epoxy resin and flexible epoxy resin, then add mixed diluent, start stirring, control the speed at 300-500r / min, stir for 10-15min, then add anatase titanium dioxide, heavy For calcium carbonate and talcum powder, the speed is controlled at 800-1200r / min. After adding anatase titanium dioxide, heavy calcium carbonate, and talc powder, it needs to be stirred for 10-15 minutes. After adding all of them, stir for another 20-30 minutes. .

[0026] (2) B component

[0027] ① See Table 2 for the formula of component B.

[0028] Table 2

[0029] c...

Embodiment 2

[0038] Embodiment 2 prepares epoxy elastic putty

[0039] (1) A component

[0040] ① See Table 4 for the formula of component A.

[0041] Table 4

[0042]

[0043] In the table: NPEL-128, YDF-172, TLA-100 are the same as Table 1.

[0044] ② Preparation of component A

[0045] The preparation method is the same as that of the preparation example 1A component.

[0046] (2) B component

[0047] ① See Table 5 for the formula of component B.

[0048] table 5

[0049] components

Raw material name and specification

Dosage, (wt%)

polyamide resin

Aradur125, amine value 340~370mgKOH / g

10

Polyether modified amine

Aradur3225, amine value 310~340mgKOH / g

25

Talc powder

Commercially available industrial products, 400 mesh

30

Ground calcium carbonate

Commercially available industrial products, 800 mesh

25

Anti-sagging agent

Fumed silica, A-200

1.5

mixed diluent

A mixture of xylene a...

Embodiment 1 and 2

[0064] 1. epoxy elastic putty (embodiment 1 and 2 system);

[0065] ② Epoxy putty is NC-16, a product of CNOOC Changzhou Coating Chemical Research Institute;

[0066] ③ The elastic putty with pure acrylic emulsion as the base resin is CTD-7305, a product of CNOOC Changzhou Paint Chemical Research Institute.

[0067] (3) The test results are shown in Table 7.

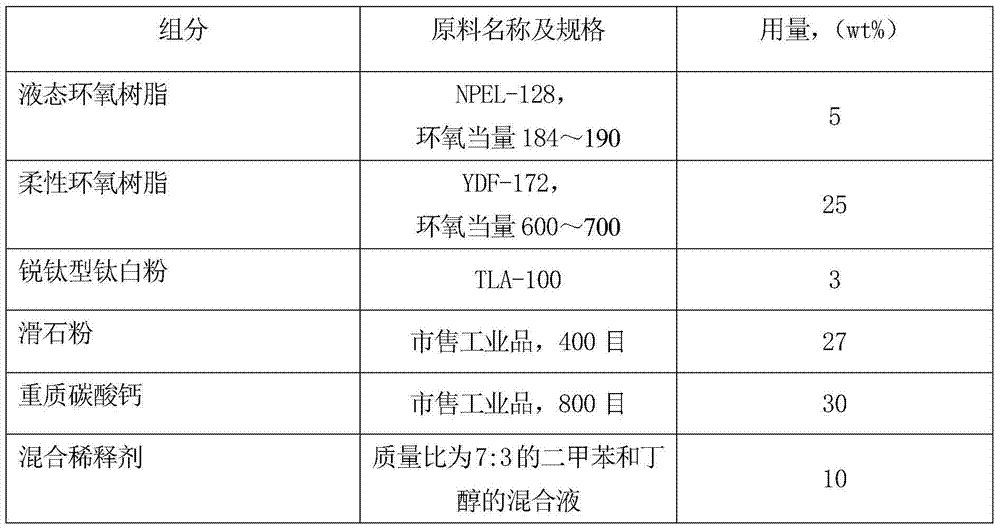

[0068] Table 7

[0069]

[0070] As can be seen from the test results of Table 7: the freezing cracking performance and the pull-off method adhesion of the epoxy elastic putty of the present invention (embodiment 1 and 2 system) are all better than the elastic putty with pure acrylic emulsion as matrix resin; the pull-off method The adhesion is comparable to epoxy putty, but the freeze cracking performance is obviously better than epoxy putty. It has been proved that the flexible epoxy resin (bisphenol A epoxy resin modified by dimer acid glycidyl ester) introduced in the A component of the present invention, the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com