Method for producing glass substrate for magnetic disks, method for producing magnetic disk, and cleaning liquid for glass substrate for magnetic disks

A technology for glass substrates and manufacturing methods, which is applied in the manufacture of base layers and disc carriers, etc., which can solve problems such as narrow intervals and increased proportions of glass substrates, and achieve the effect of low roughness and high smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0069] A glass substrate for a magnetic disk is usually produced through rough grinding, shape processing, finish grinding, end surface grinding, main surface grinding (first grinding, second grinding), chemical strengthening treatment, and the like.

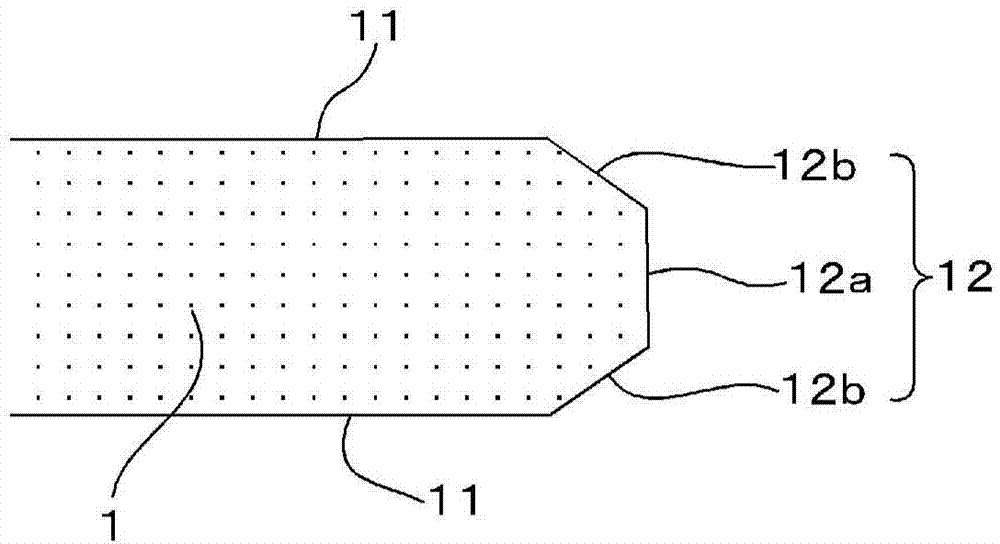

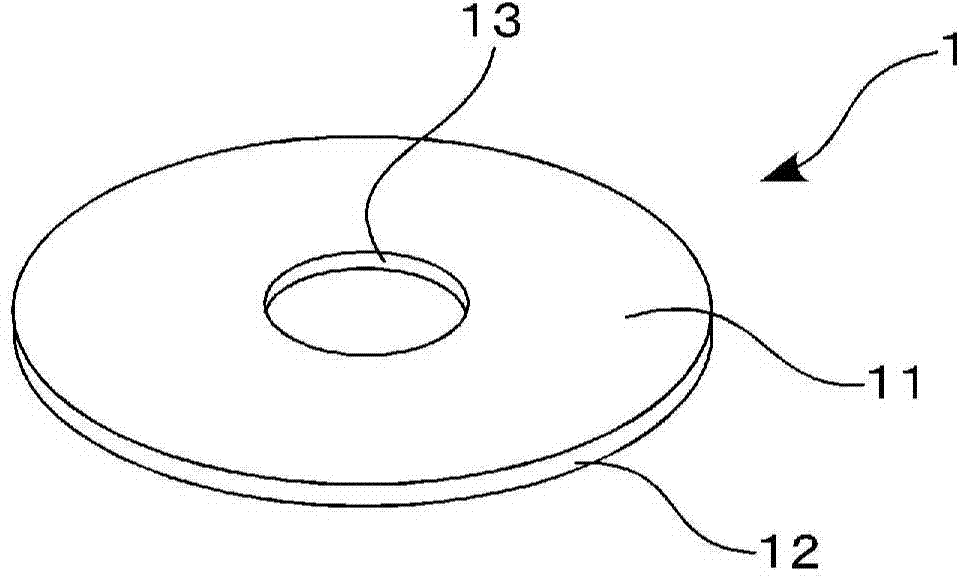

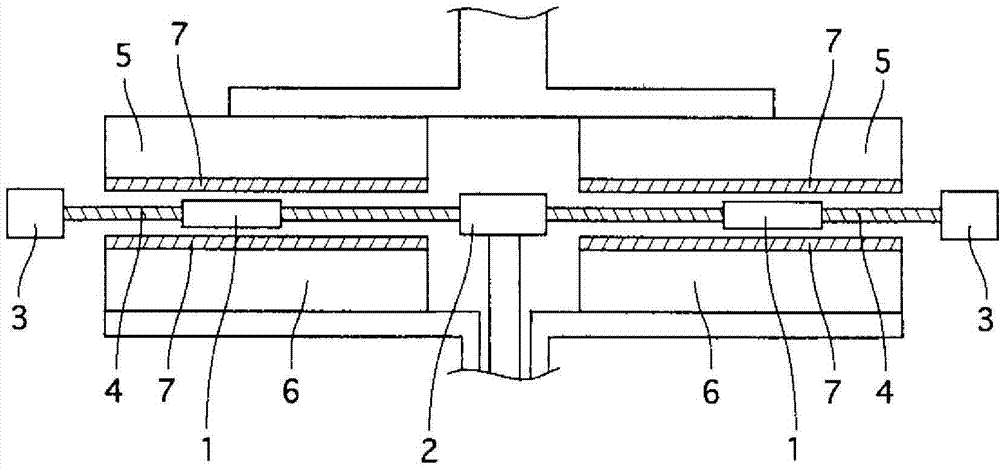

[0070] In the manufacture of this glass substrate for magnetic disks, first, molten glass is molded into a disk-shaped glass substrate (glass disk) by direct press. In addition, in addition to using such a direct press method, it is also possible to cut the sheet glass produced by the down-draw method or the float method into predetermined sizes, and obtain a glass substrate (glass disk). Next, the formed glass substrate (glass disk) is ground to improve dimensional accuracy and shape accuracy. In this grinding process, the main surface of the glass substrate is generally ground with hard abrasive grains such as diamond using a double-side grinding device. By grinding the main surface of the glass substrate in this way, not onl...

no. 2 Embodiment approach

[0112] As shown in the above configuration 11, the second embodiment of the present invention is characterized in that, for example, in the cleaning treatment of cleaning the glass substrate with a cleaning solution containing a cleaning agent after the grinding treatment of the main surface of the glass substrate, This cleaning process includes a process of bringing the glass substrate into contact with a cleaning solution that has etching properties for the glass substrate and that contains tetramethylammonium ions.

[0113] More preferably, as shown in the above-mentioned structure 10, the above-mentioned cleaning treatment includes the treatment of contacting the glass substrate with a cleaning solution containing tetramethylammonium ions, while suppressing the total amount of sodium ions and potassium ions in the cleaning solution to be less than 200ppm While cleaning.

[0114] The inventors of the present invention investigated a method for suppressing the increase in th...

Embodiment 1

[0149] After the following (1) rough grinding treatment, (2) shape processing treatment, (3) finish grinding treatment, (4) end surface grinding treatment, (5) primary surface grinding treatment, (6) chemical strengthening treatment, (7) The second main surface grinding process, (8) Washing process, and the glass substrate for magnetic discs of this Example were manufactured.

[0150] First, a disk-shaped glass substrate made of aluminosilicate glass is obtained from molten glass by direct press molding using an upper mold, a lower mold, and a cylindrical mold. In addition, besides such direct press, a glass substrate can be obtained by cutting sheet glass produced by a down-draw method or a float method into a predetermined size. As the aluminosilicate glass, SiO containing 58% by weight to 75% by weight is used. 2 , 5% to 23% by weight of Al 2 o 3 , 3% to 10% by weight of Li 2 O, 4% to 13% by weight of Na 2 Glass for chemical strengthening of O.

[0151] (1) Rough grin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap