Application of prinsepiautilis Royle tender bud extractive to whitening product and whitening product

A green thorn point and extract technology, which is applied in the field of green thorn point extract, can solve problems such as safety, component instability, application restrictions, etc., and achieve good safety, prominent whitening effect, and high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: the preparation of green thorn point extract

[0033] Take 2 kg of green thorn tips (the green thorn tips are collected from Lijiang, Yunnan, and dried in the sun), crush them, soak them in 20 liters of 70% ethanol at room temperature for one day, and extract them under reflux for 60 minutes. After filtering out the extract, add 16 liters of 70% ethanol, reflux extraction for 40 minutes, and filter. The two extracts were combined and concentrated to dryness in vacuo to obtain 360 g of Punjabis punctatus primary extract (codenamed PUE), with a yield of 18%.

Embodiment 2

[0034] Embodiment 2: the preparation of green thorn point polyphenol

[0035] Get the first extract 100g of the green thorn tip prepared in Example 1, add water to dissolve, and carry out chromatography on AB-8 macroporous adsorption resin. The ratio of the amount of extract to the weight of resin is about 1:20. Sequentially eluted with water, 30% ethanol, 60% ethanol and 95% ethanol, each gradient eluted with 4-5 column volumes, and the flow rate was 2-3 column volumes / hour. After the elution, the 30% ethanol part (PU30), the 60% ethanol part (PU60) and the 95% ethanol part (PU95) were concentrated to dryness respectively, of which the 30% ethanol part was 20g in total, the 60% ethanol part was 43g in total, 95 A total of 15g of % ethanol parts.

Embodiment 3

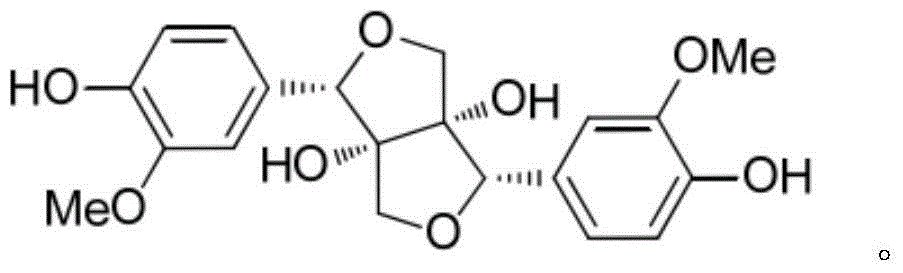

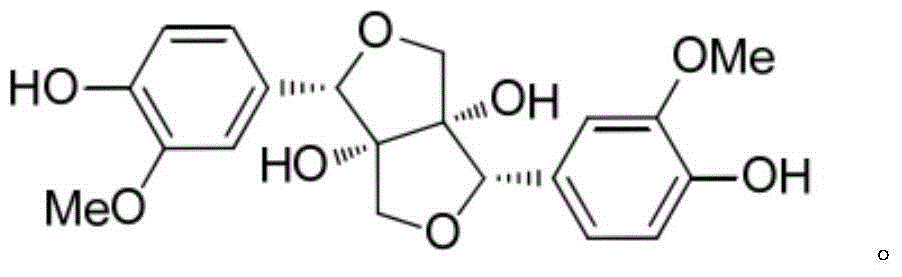

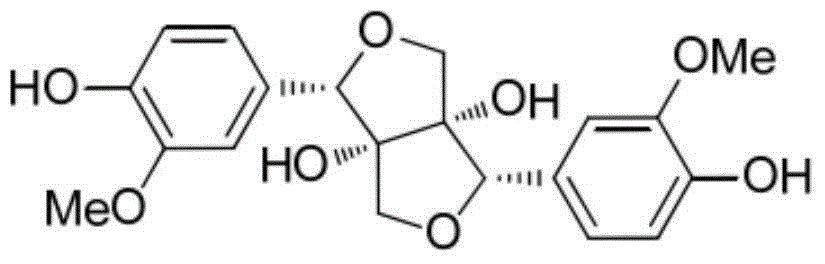

[0036] Example 3: Isolation and structural identification of green thorn tip whitening active compound

[0037] Take 30 g of the 60% ethanol part in Example 2, go to silica gel column chromatography, and use chloroform: the volume ratio of methanol is respectively 20:1, 15:1, 10:1, 5:1, and 1:1 to carry out gradient washing Take off, get 5 parts respectively. Chloroform:methanol ratio 5:1 eluted part was then chromatographed with C18 reverse-phase preparative column, gradient elution was carried out with 20% methanol, 40% methanol, 60% methanol, 90% methanol, and 40% methanol The eluted part was subjected to Sephadex LH-20 gel column chromatography and eluted with 100% ethanol to obtain compound 1, whose structure was identified by physical and chemical constants and modern spectroscopy means (MS, NMR).

[0038]Compound 1: Pale yellow powder, ESI-MS gives the molecular ion peak as m / z: 413[M+Na]+, combined with hydrogen and carbon spectrum to determine the molecular formula i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com