Wafer cutting device

A cutting device and wafer technology, which is applied to fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problems of easy tool wear, slow etching speed, high consumption, etc., and achieve good processing quality and heat affected zone. Small, high cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail in conjunction with the accompanying drawings and specific embodiments.

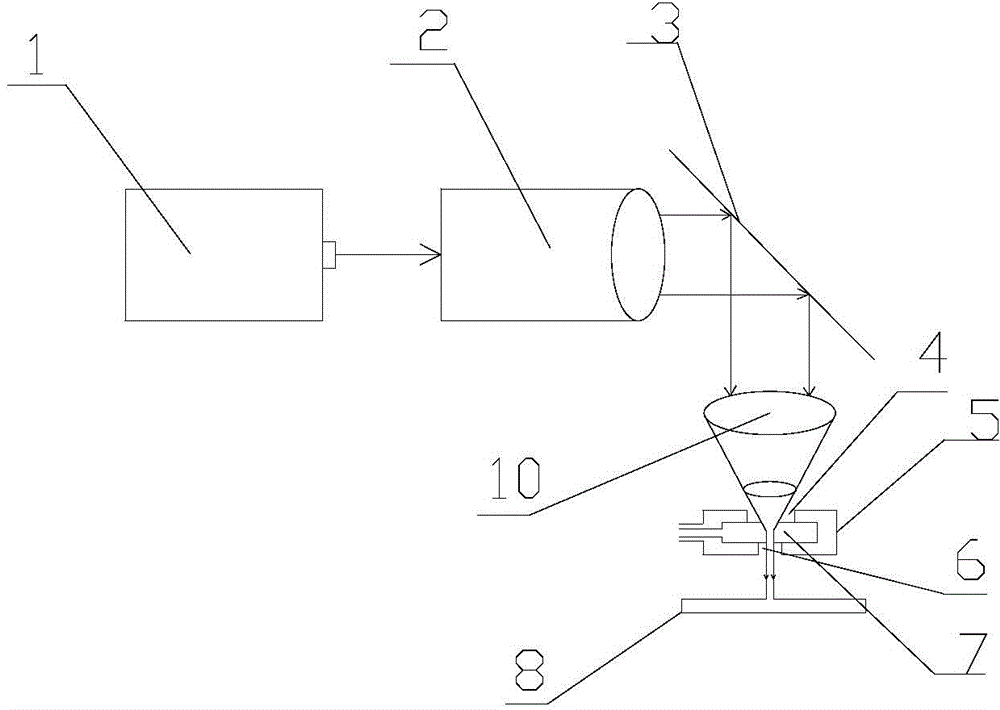

[0015] like figure 1 As shown, the wafer cutting device of the present invention includes a laser 1 , a beam expander 2 , a reflector 3 , a focusing system 10 , a water guide system and a workbench 8 . The wafer to be cut is placed on the workbench 8 , and the laser light generated by the laser 1 enters the focusing system 10 after passing through the beam expander 2 and the reflector 3 .

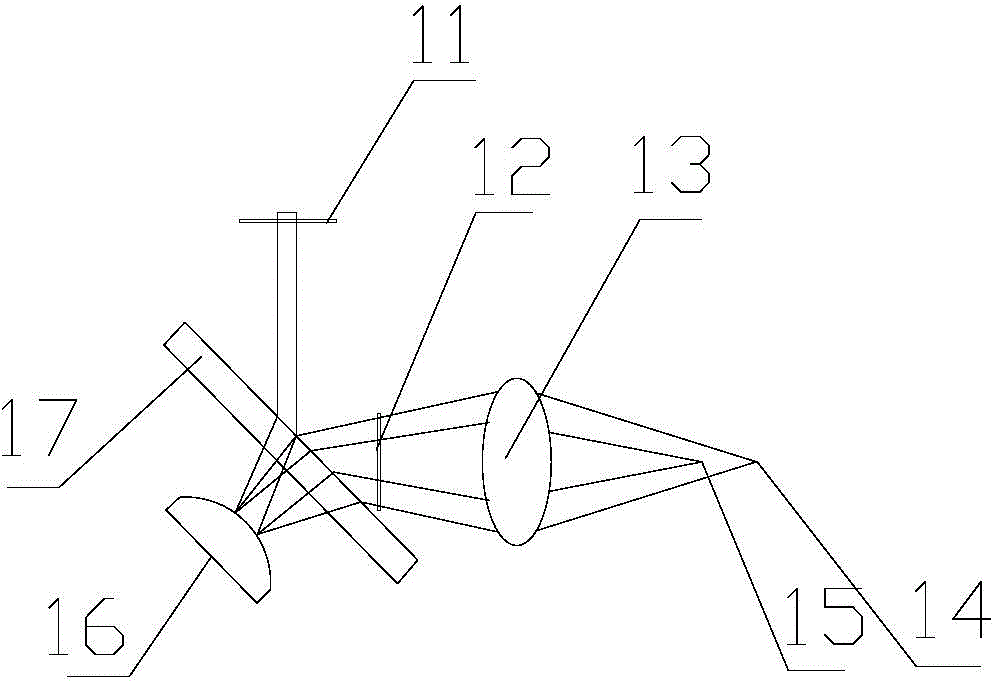

[0016] The focus system of the present invention is a double focus system, such as figure 2 As shown, it is composed of a plano-convex mirror 16, a plane beam splitter 17, a focusing mirror 13, a half-wavelength wave plate 11 and a quarter-wavelength wave plate 12. The laser beam forms parallel light after passing through the mirror and enters the focusing system , in the focusing system, first, the parallel light is converged into one beam through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com