Coking wastewater purifying agent as well as preparation method and application thereof

A technology for coking wastewater and purifying agent, which is applied in chemical instruments and methods, natural water treatment, water/sludge/sewage treatment, etc. The problem of high concentration can achieve the effect of good synergy, fast sedimentation and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Weigh 25kg of ferric sulfate, 20kg of aluminum sulfate, 15kg of magnesium chloride and 10kg of zinc sulfate, mix well and dry at 100°C for 90 minutes to make a coagulant; weigh 5kg of PAM and 8kg of bentonite, mix well and dry at 80°C , dried for 45 minutes to make a coagulant; weigh 11kg of zeolite powder and 6kg of chitosan, mix thoroughly and dry at 60°C for 60 minutes to make a accelerator.

Embodiment 2

[0046] Weigh 28kg of ferric chloride, 15kg of aluminum sulfate, 16kg of magnesium sulfate, and 12kg of zinc chloride, mix thoroughly and dry at 90°C for 120 minutes to make a coagulant; weigh 5kg of PAM, 7kg of bentonite, mix fully Dry at 100°C for 30 minutes to make a coagulant; weigh 12kg of zeolite powder and 5kg of chitosan, mix well, and dry at 50°C for 45 minutes to make an accelerator.

Embodiment 3

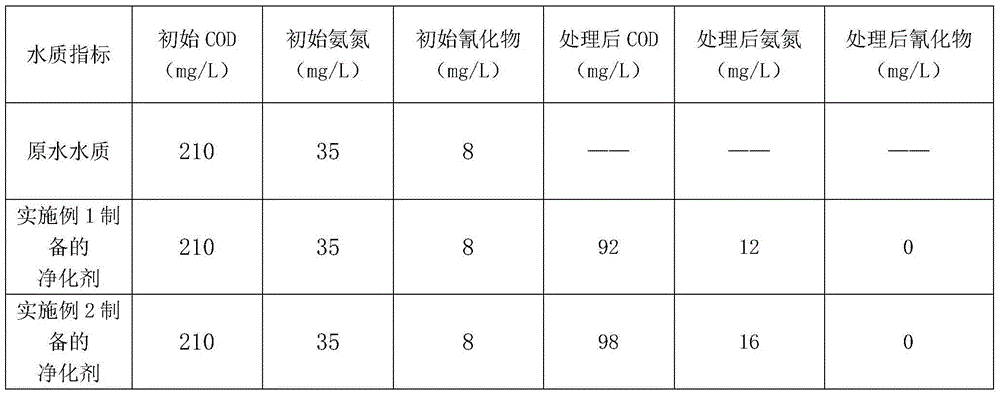

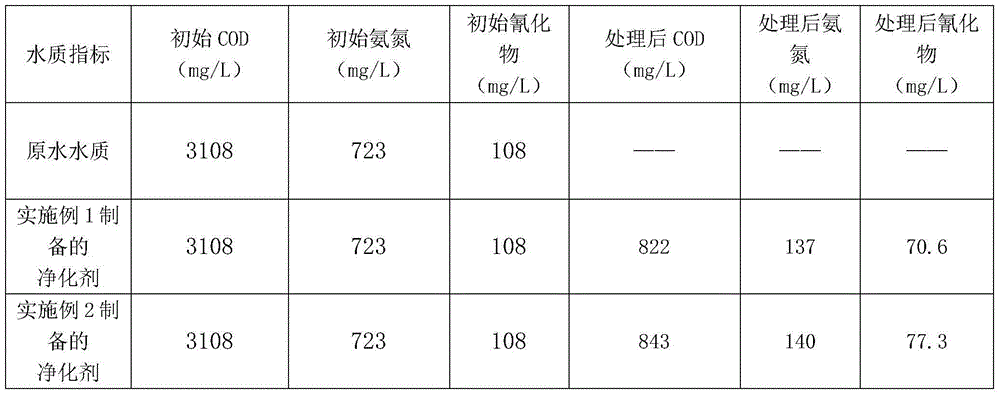

[0048] Take two parts of low-concentration coking wastewater 5000mL and place them in two 5000mL beakers respectively, add the purification agent prepared in Example 1 and Example 2 of the present invention respectively, first add 0.6g of coagulant, stir for 10 minutes, and then add coagulant 0.3g, stirred for 3 minutes, then added 0.1g of accelerator, stirred for 2 minutes, left to settle for 20 minutes, then took the supernatant for measurement; the results are as follows:

[0049]

[0050] The result shows: respectively add the cleaning agent prepared by embodiment 1 of the present invention and embodiment 2 to treat low-concentration coking wastewater, its COD removal rate is respectively 56.2% and 53.3%, ammonia nitrogen removal rate is respectively 65.7% and 54.3%, cyanide removal rate Both are 100%. The indicators of various pollutants are significantly reduced, and it can be used as an advanced treatment method for coking wastewater.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com