Pretreatment method for step-by-step demulsification and flocculation of DMTO catalyst centrifugal mother liquid through integrated internal-circulation reactor

A centrifuge mother liquor and reactor technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, natural water treatment, etc., can solve the incomplete dissolution of bundled silica-aluminophosphate gel, phosphorus and aluminum gel interference Subsequent treatment, difficult dehydration of dissolved substances, etc., to achieve the effect of saving dosage, saving dilution water, and eliminating reaction back-dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

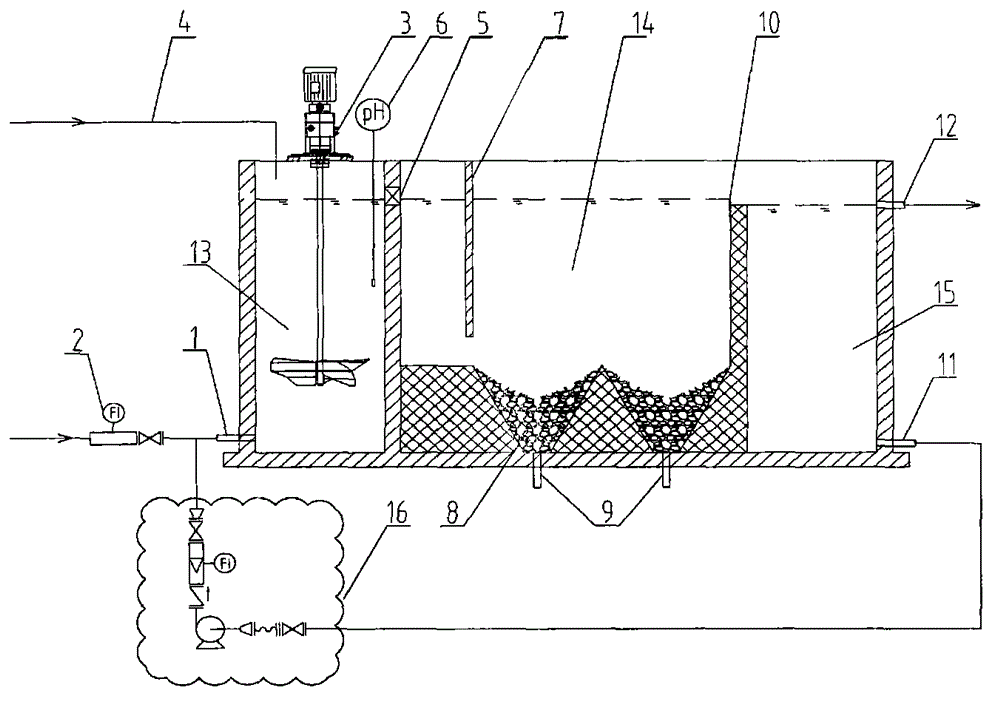

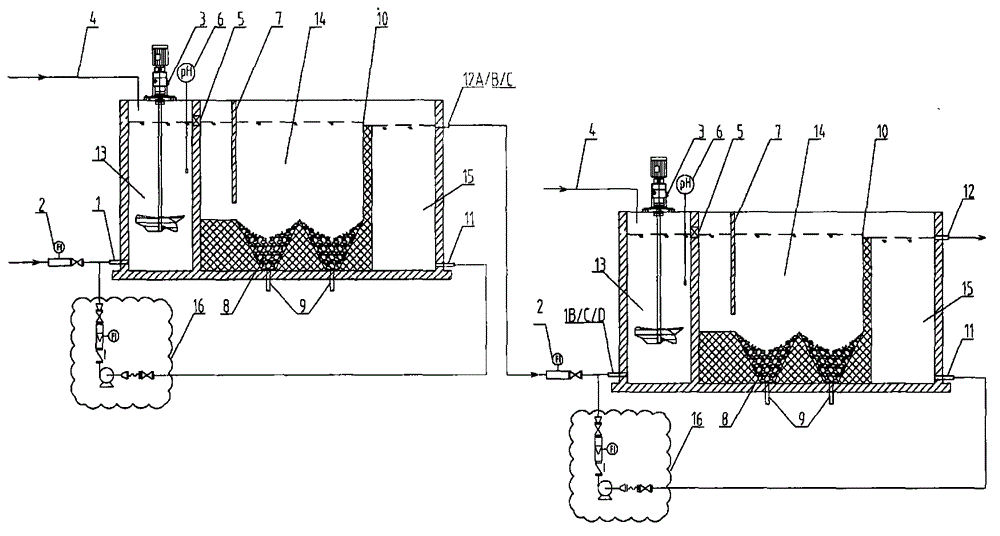

[0023]Embodiment 1: In this embodiment, the pretreatment method of demulsification and flocculation of the DMTO catalyst centrifuged mother liquor is carried out step by step by using the integration-internal circulation reactor, which is composed of the integration-internal circulation reactor device A / B / C / D It is realized by connecting the pre-demulsification reactor A, the demulsification reactor B, the primary flocculation reactor C and the secondary flocculation reactor D in series and running step by step, specifically as follows:

[0024] One, first, the DMTO catalyst centrifugal mother liquor is diluted with water in proportion, centrifugal mother liquor: tap water=1: (3~5);

[0025] 2. The diluted centrifugal mother liquor is continuously injected into the pre-demulsification reaction tank A13 through the liquid inlet flowmeter A2 and the water inlet A1 of the pre-demulsification reactor according to the designed unit time, and the pre-demulsification reaction is start...

specific Embodiment approach 2

[0029] Embodiment two: the difference between this embodiment and embodiment one is: the horizontal position of the water outlet A12 of the pre-emulsification reactor is higher than the horizontal position of the water outlet B12 of the demulsification reactor by 20 cm, and the water outlet B12 of the demulsification reactor The horizontal position is 20cm higher than the horizontal position of the water outlet C12 of the primary flocculation reactor, and the horizontal position of the water outlet C12 of the primary flocculation reactor is 20cm higher than the horizontal position of the water outlet D12 of the secondary flocculation reactor. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0030] Specific embodiment three: the difference between this specific embodiment and specific embodiment one or two is: first pre-demulsification reaction tank A13 and sedimentation tank A14 are filled with water, and the pH value in A13, A14 is adjusted to 6 with pre-demulsifier ~6.5; similarly, the demulsification reaction tank B13 and sedimentation tank B14 are also filled with water, and the pH value in B13 and B14 is pre-adjusted to between 1.5 and 2.0 with a demulsifier, and the primary flocculation reaction tank C13, sedimentation tank Pool C14, secondary flocculation reaction pool D13, and sedimentation pool D14 are filled with water, and the pH values in C13, C14, D13, and D14 are pre-adjusted to 4.5-5.0 and 8.5-9.0 respectively with calcium hydroxide solution, and then The centrifugal mother liquor is injected into the pre-demulsification reaction tank A13 from the centrifuge mother liquor inlet A1. Others are the same as in the first or second embodiment.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com