Method for extracting platycodin D from platycodon grandiflorum

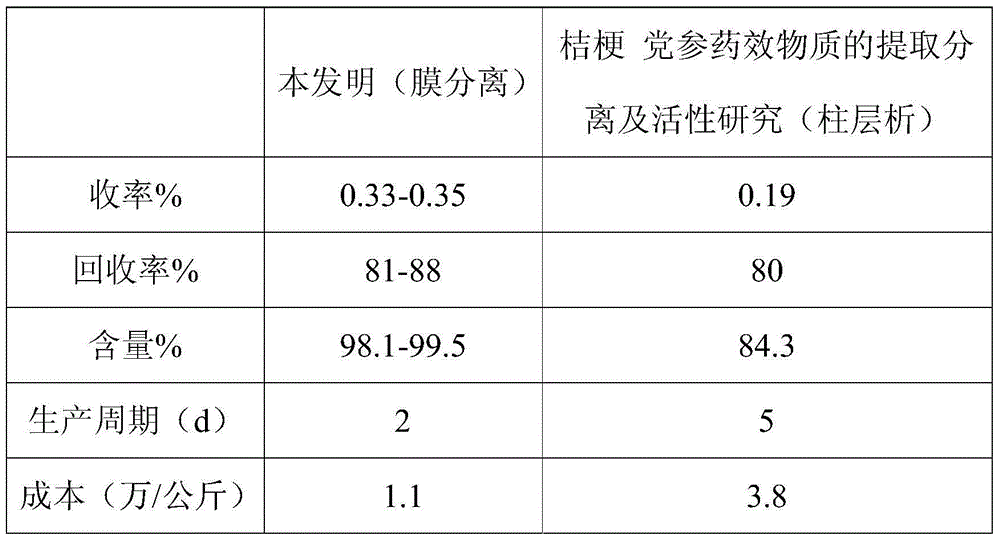

A technology of platycodon saponins and platycodon grandiflorum, which is applied in the field of platycodon grandiflorum extraction and separation, can solve problems such as less separation and purification of platycodon grandiflorum saponins D, and achieve the effects of less solvent damage, improved operability, and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Take 1 kg of Platycodon grandiflora raw material and pulverize it, use 90% ethanol aqueous solution with 5 times the mass of the raw material to extract with stirring at 80°C, and extract twice in total to obtain the extract.

[0040] The extract is separated by an ultrafiltration membrane with a molecular weight cut-off of 10,000-20,000 dalton to obtain an ultrafiltrate and a dope, and the ultra-filtrate is separated by a nanofiltration membrane with a molecular weight cut-off of 800-1000 dalton to obtain a nanofiltration and a dope, and a dope drying. Dissolve the dry matter in 8 times the amount of acetonitrile at 80°C, add activated carbon for decolorization, filter, add acetonitrile solution of 10% acetone, put it in the refrigerator to crystallize overnight, and filter with suction to obtain 3.39 g of white powdery substance, which is platycodon saponin D. The content is 98.4%, and the recovery rate is 83.4%.

Embodiment 2

[0042] Take 1 kg of Platycodon grandiflora raw material and pulverize it, and extract it with 90% ethanol aqueous solution with 5 times the mass of the raw material at 40° C. with stirring, and extract twice in total to obtain an extract.

[0043] The extract is separated by an ultrafiltration membrane with a molecular weight cut-off of 5000-8000dalton to obtain an ultrafiltrate and a dope, and the ultrafiltrate is separated by a nanofiltration membrane with a molecular weight cut-off of 400-600dalton to obtain a nanofiltration and a dope. drying. Dissolve the dry matter in 4 times the amount of 80% isopropanol at 60°C, add activated carbon for decolorization, filter, add 25% acetone in isopropanol solution, put it in the refrigerator to crystallize overnight, and filter with suction to obtain 3.53g of white powdery substance, which is Platycodon saponin D. The content is 99.5%, and the recovery rate is 87.8%.

Embodiment 3

[0045] Take 1 kg of Platycodon grandiflora raw material and pulverize it, and extract with 90% ethanol aqueous solution with 5 times the mass of the raw material at 70°C with stirring, and extract twice in total to obtain an extract.

[0046] The extract is separated by an ultrafiltration membrane with a molecular weight cut-off of 2000-5000dalton to obtain an ultrafiltrate and a dope, and the ultrafiltrate is separated by a nanofiltration membrane with a molecular weight cut-off of 150-450dalton to obtain a nanofiltrate and a dope, and a dope drying. Dissolve the dry matter with 10 times the amount of n-butanol at 100°C, add activated carbon for decolorization, filter, add acetone with 50% n-butanol solution, put it in the refrigerator to crystallize overnight, and filter with suction to obtain 3.3g of white powdery substance, which is platycodon saponin d. The yield is 0.33%, the content is 98.1%, and the recovery rate is 80.9%. Embodiment Four

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com