Polyester resin for ultra-weather-proof powder coating, powder coating with resin and preparing method for powder coating

A powder coating, polyester resin technology, applied in powder coatings, polyester coatings, coatings, etc., can solve the problems of chalking, easy breakage of chemical bonds, discoloration, etc., and achieve good film formation, strong hydrophobicity, and strong water resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A polyester resin for super weather-resistant powder coatings, its raw material composition and molar ratio are: 5.01mol of neopentyl glycol, 1.93mol of 1,3-cyclohexanediol, 1H, 1H, 10H, 10H-perfluoro- 0.76 mol of 1,10-decanediol; 6.0 mol of terephthalic acid, 1.6 mol of tetrafluoroisophthalic acid, 0.4 mol of hexafluoroglutaric acid; 0.013 mol of monobutyltin oxide.

[0020] The preparation method of polyester resin for super weather resistance powder coating comprises the following steps:

[0021] A. Add the neopentyl glycol, 1,6-cyclohexanediol, 1H, 1H, 10H, 10H-perfluoro-1, 10-decanediol in the formula amount into a three-necked flask equipped with a stirring and reflux condenser , mixed and stirred and heated and melted at 130°C;

[0022] B. Add the amount of terephthalic acid, hexafluoroglutaric acid and monobutyltin oxide catalyst, and gradually heat up in nitrogen atmosphere until no distillate is evaporated; the reaction temperature is not higher than 245 ° C,...

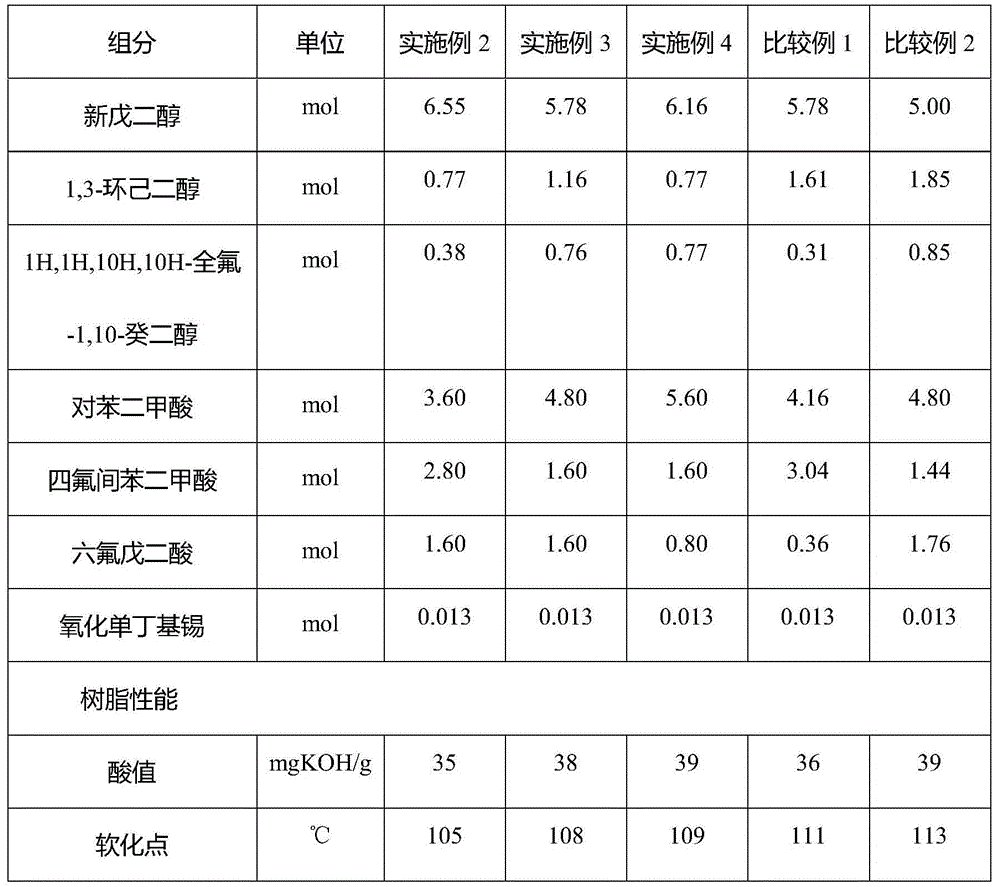

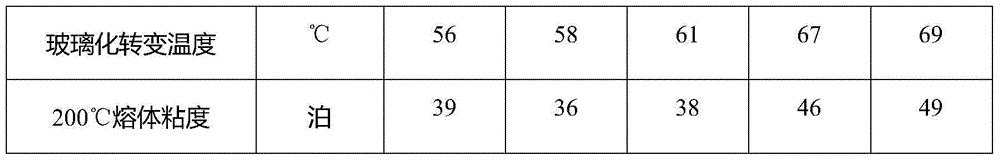

Embodiment 2-4 and comparative example 1-2

[0026] According to the formulation amounts listed in Table 1 below, the polyester resins of Examples 2-4 and Comparative Examples 1-2 were obtained according to the same preparation method as Example 1.

[0027] Table 1 Composition and properties of polyester resin

[0028]

[0029]

[0030] As can be seen from Table 1, the softening point and glass transition temperature of the polyester resin of Example 2-4 are all lower than Comparative Example 1-2 whose raw material content is not within the scope of the present invention; Example 1 and 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com