A kind of high temperature resistant adhesive resin and preparation method thereof

A technology of bonding resin and high temperature resistance, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesives, etc. Effects that are easy to store and transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

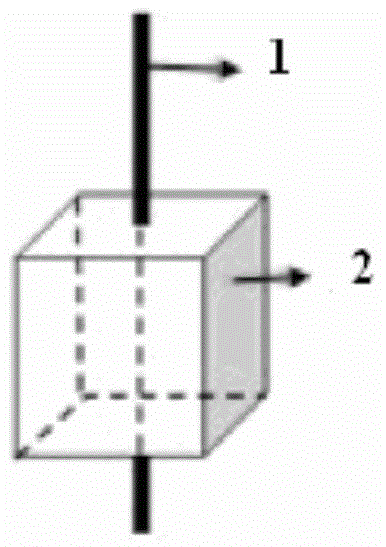

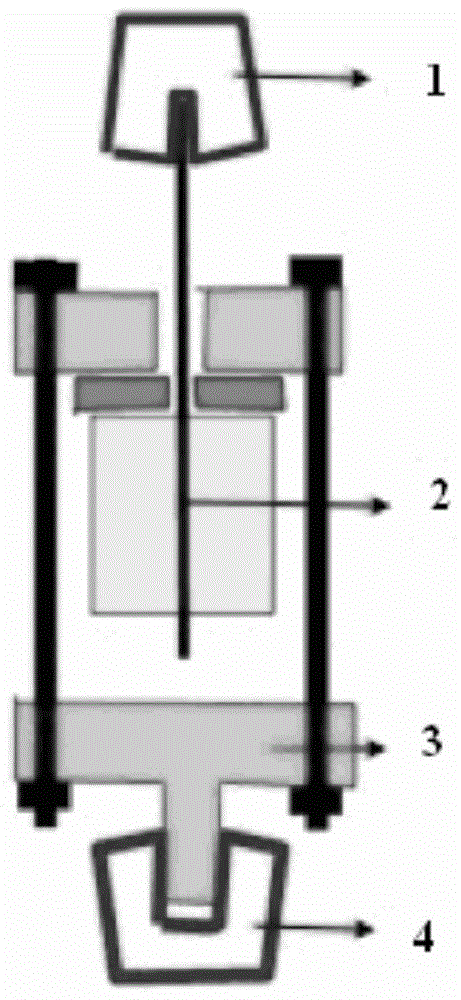

Image

Examples

Embodiment 1

[0056] The content of each raw material component is as follows in the present embodiment:

[0057]

[0058] The melt index of the polypropylene-maleic anhydride styrene co-graft at 190°C under a pressure of 2.16kg is 5-8g / 10min;

[0059] The melt index of the polyethylene-maleic anhydride styrene co-graft at 190°C under a pressure of 2.16kg is 5-8g / 10min;

[0060] The melt index of the glycidyl methacrylate grafted ethylene propylene copolymer at 190°C under a pressure of 2.16kg is 5-8g / 10min;

[0061] The melt index of the nylon 6 at 230°C under a pressure of 2.16kg is 5-8g / 10min;

[0062] Described viscosity regulator is polyester wax, and molecular weight is 2300, and density is 0.92g / cm 3

[0063] Antioxidant is Antioxidant 1010.

[0064] The specific preparation method is as follows:

[0065] 1) At 220°C, add nylon 6 into the reactor and heat to melt;

[0066] 2) Then add antioxidant and viscosity regulator to melt and mix;

[0067] 3) Finally, the polypropylene-...

Embodiment 2

[0069] The content of each raw material component is as follows in the present embodiment:

[0070]

[0071] The melt index of the polypropylene-maleic anhydride styrene co-graft at 190°C under a pressure of 2.16kg is 5-8g / 10min;

[0072] The melt index of the polyethylene-maleic anhydride styrene co-graft at 190°C under a pressure of 2.16kg is 5-8g / 10min;

[0073] The melt index of the glycidyl methacrylate grafted ethylene propylene copolymer at 190°C under a pressure of 2.16kg is 5-8g / 10min;

[0074] The melt index of the nylon 6 at 230°C under a pressure of 2.16kg is 5-8g / 10min;

[0075] Described viscosity regulator is polyester wax, and molecular weight is 2300, and density is 0.92g / cm 3

[0076] Antioxidant is Antioxidant 1010.

[0077] The specific preparation method is as follows:

[0078] 1) At 230°C, add nylon 6 into the reactor and heat to melt;

[0079] 2) Then add antioxidant and viscosity regulator to melt and mix;

[0080] 3) Finally, the polypropylen...

Embodiment 3

[0082] The content of each raw material component is as follows in the present embodiment:

[0083]

[0084] The melt index of the polypropylene-maleic anhydride styrene co-graft at 190°C under a pressure of 2.16kg is 5-8g / 10min;

[0085] The melt index of the polyethylene-maleic anhydride styrene co-graft at 190°C under a pressure of 2.16kg is 5-8g / 10min;

[0086] The melt index of the glycidyl methacrylate grafted ethylene propylene copolymer at 190°C under a pressure of 2.16kg is 5-8g / 10min;

[0087] The melt index of the nylon 6 at 230°C under a pressure of 2.16kg is 5-8g / 10min;

[0088] Described viscosity regulator is polyester wax, and molecular weight is 2300, and density is 0.92g / cm 3

[0089] Antioxidant is Antioxidant 1010.

[0090] The specific preparation method is as follows:

[0091] 1) At 240°C, add nylon 6 into the reactor and heat to melt;

[0092] 2) Then add antioxidant and viscosity regulator to melt and mix;

[0093] 3) Finally, the polypropylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com