High-dye-uptake-rate polyester fiber and preparation method thereof

A polyester fiber, dye uptake technology, applied in the direction of fiber chemical characteristics, single-component polyester rayon, rayon manufacturing, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] A preparation method of high dye-uptake polyester fiber, comprising the following steps:

[0077] (1) Preparation of amino fatty acid ethylene glycol ester:

[0078] 1) Add dodecanedicarboxylic acid and methanol into the reactor in a molar ratio of 1:1.5, under the catalysis of concentrated sulfuric acid, heat to 80°C, reflux for esterification, cool, separate and purify to obtain dodecanedicarboxylic acid Acid monomethyl ester; Described concentrated sulfuric acid refers to the sulfuric acid that mass concentration is 70%, and the concentrated sulfuric acid add-on is 3wt% of dodecane dicarboxylic acid;

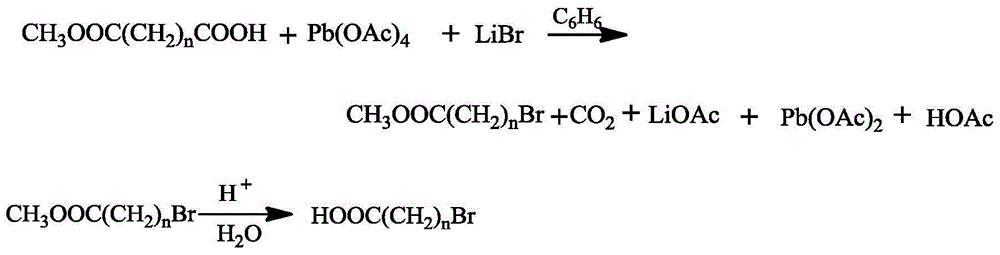

[0079] 2) Dissolve the monomethyl dodecanedicarboxylate, lead tetraacetate and lithium bromide in benzene (molar ratio 1:1:1), wherein the monomethyl dodecanedicarboxylate concentration is 0.05mol / L , under a nitrogen atmosphere, react at 80 ° C, reflux, when no more gas is produced, add a certain amount of dilute sulfuric acid to react for 2 hours, then wash, purify ...

Embodiment 2

[0100] A preparation method of high dye-uptake polyester fiber, comprising the following steps:

[0101] (1) Preparation of amino fatty acid ethylene glycol ester:

[0102] 1) Add pentacodecanedicarboxylic acid and methanol into the reactor in a molar ratio of 1:1.5, under the catalysis of concentrated sulfuric acid, heat to 110°C, reflux for esterification, cool, separate and purify to obtain pentacodecane Dicarboxylic acid monomethyl ester; Described concentrated sulfuric acid refers to the sulfuric acid that mass concentration is 70%, and the concentrated sulfuric acid add-on is 3wt% of pentacosane dicarboxylic acid;

[0103] 2) The monomethyl pentacodecanedicarboxylate, lead tetraacetate and lithium bromide are dissolved in benzene (molar ratio 1:1:1), wherein the concentration of monomethyl pentacodecanedicarboxylate is 0.07mol / L, under nitrogen atmosphere, react at 85°C, reflux, when no more gas is generated, add a certain amount of dilute sulfuric acid to react for 3 ...

Embodiment 3

[0125] A preparation method of high dye-uptake polyester fiber, comprising the following steps:

[0126] (1) Preparation of amino fatty acid ethylene glycol ester:

[0127] 1) Add pentadecanedicarboxylic acid and methanol into the reactor in a molar ratio of 1:1.5, under the catalysis of concentrated sulfuric acid, heat to 85°C, reflux for esterification, cool, separate and purify to obtain pentadecanedicarboxylic acid acid monomethyl ester; described concentrated sulfuric acid refers to the sulfuric acid that mass concentration is 70%, and the concentrated sulfuric acid add-on is 3wt% of pentadecanedicarboxylic acid;

[0128] 2) Dissolve the monomethyl pentadecanedicarboxylate, lead tetraacetate and lithium bromide in benzene (molar ratio 1:1:1), wherein the concentration of monomethyl pentadecanedicarboxylate is 0.08mol / L , under nitrogen atmosphere, react at 90°C, reflux, when no more gas is produced, add a certain amount of dilute sulfuric acid to react for 2.5 hours, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com