Patents

Literature

39results about How to "Structural regularity is not destroyed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

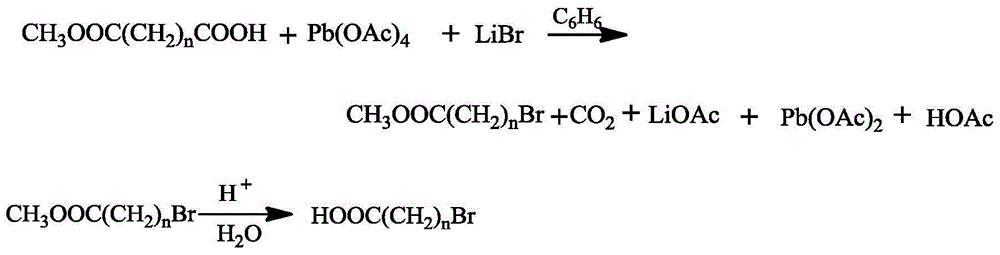

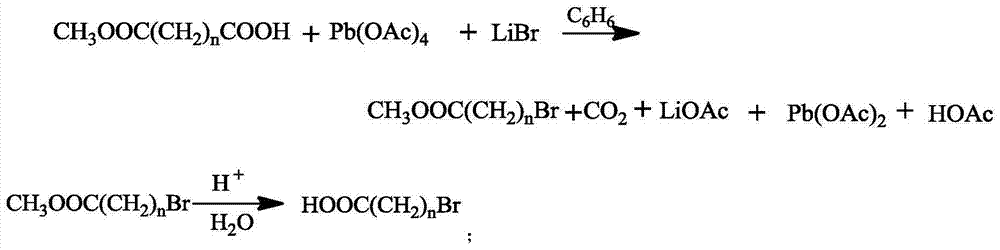

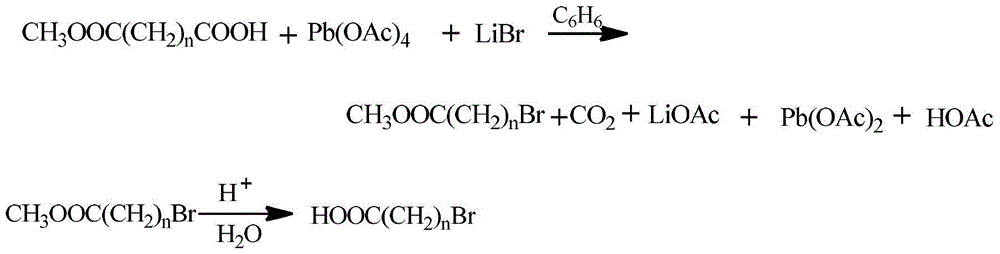

Composite differential shrinkage yarn and preparation method thereof

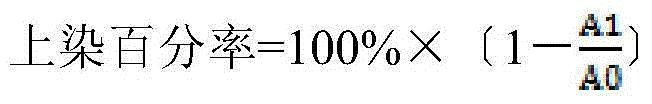

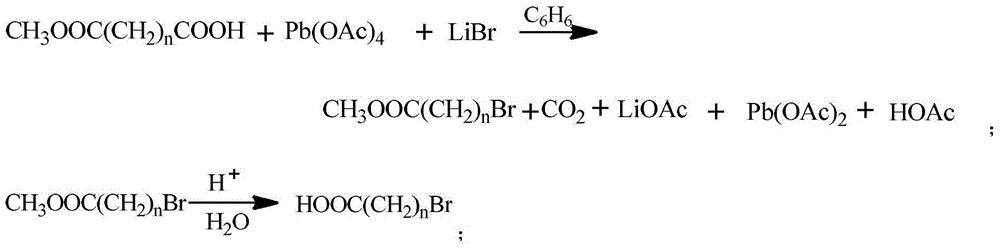

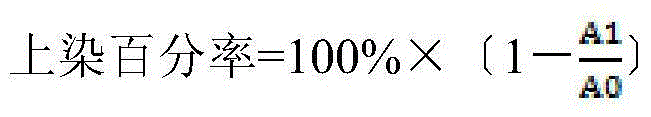

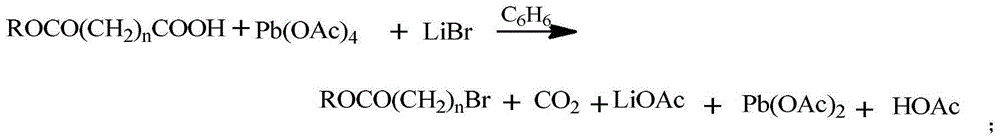

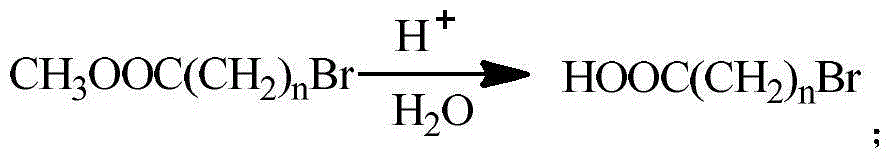

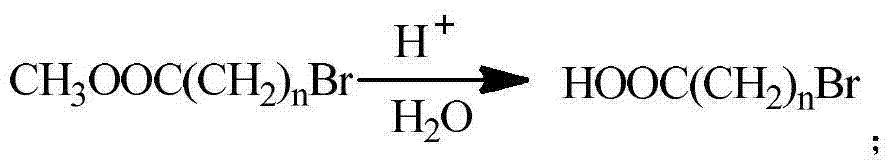

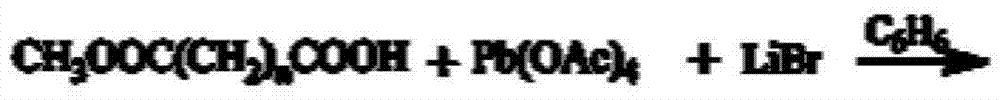

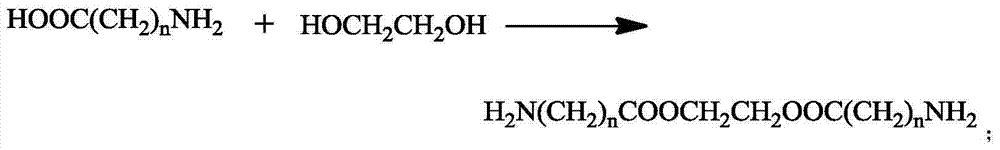

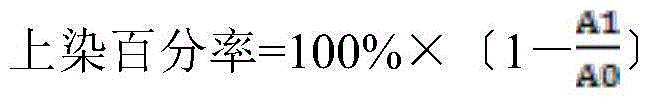

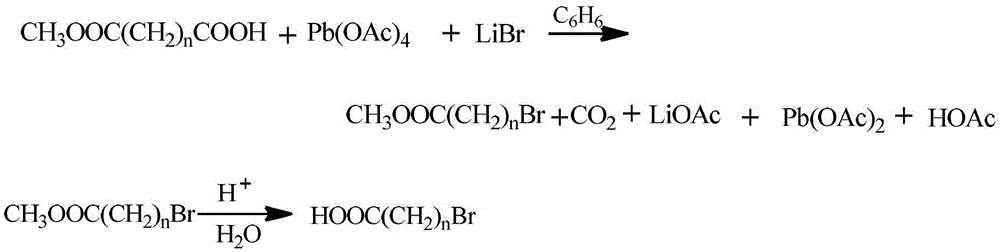

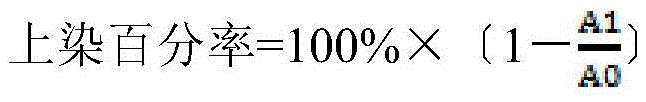

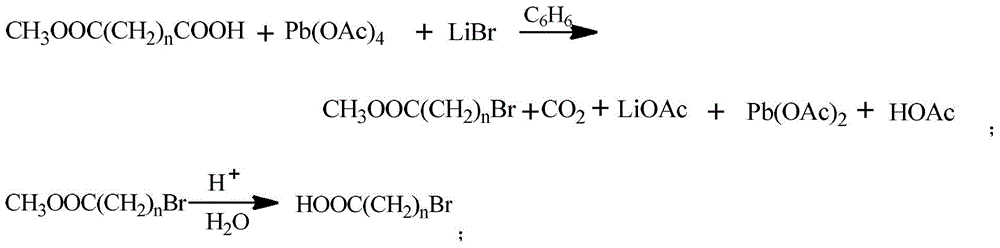

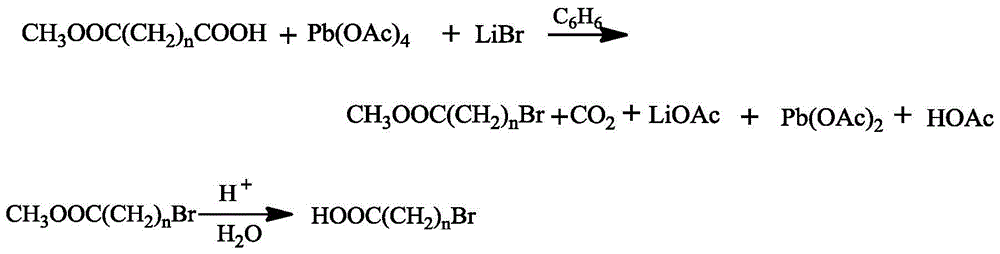

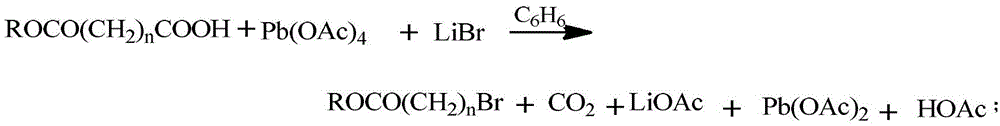

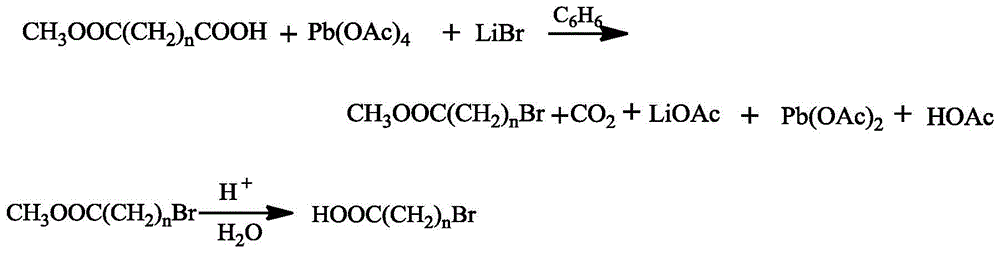

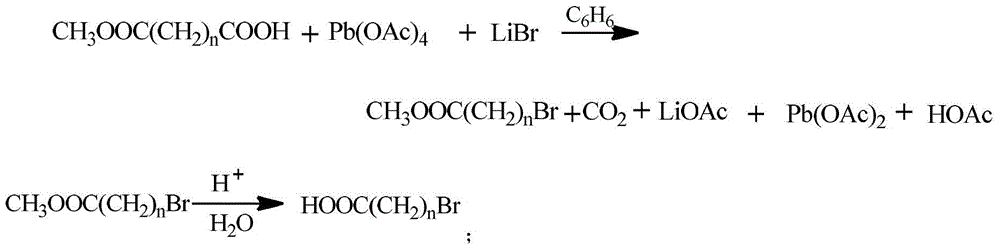

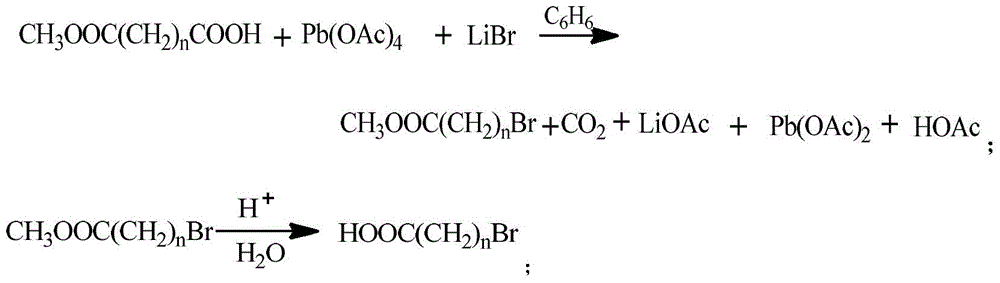

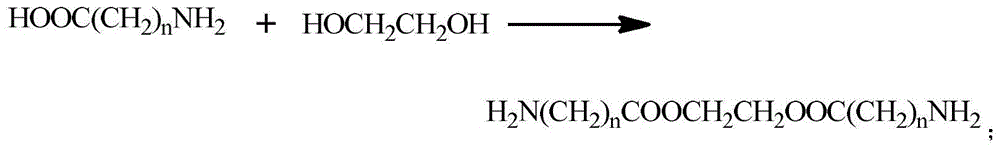

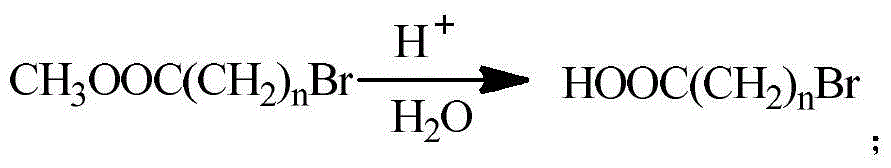

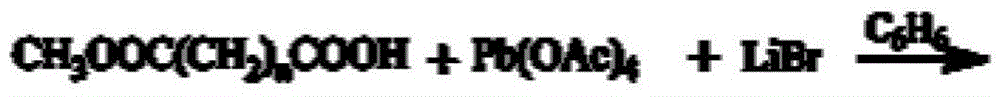

The invention relates to a composite differential shrinkage yarn and a preparation method thereof. The composite differential shrinkage yarn is formed by compositing of a POY (polyester pre-oriented yarn) body and an FDY (fully drawn yarn) body, both the POY body and the FDY body are made of modified polyester by means of spinning, the modified polyester is formed by polyester and amino fatty acid gylcol ester, the amino fatty acid gylcol ester is scattered among molecular chains of the polyester, and a hydrogen-bond interaction among the amino fatty acid gylcol ester and the molecular chains of the polyester enables opposite positions of the amino fatty acid gylcol ester and the molecular chains of the polyester to be fixed; in the condition with temperature ranging from 90 DEG C to 130 DEG C, free volume spaces among molecular chains inside a fiber of the composite differential shrinkage yarn are enlarged by 20-30v / v%. The composite differential shrinkage yarn has the advantages that the free volume of polyester fibers is increased by the aid of fatty acid ester, so that diffusing degree of dye is improved, dyeing property of the polyester fibers is improved, and the composite differential shrinkage yarn is applicable to fashion fabric, decorative fabric and the like formed by means of spinning, knitting and warp knitting.

Owner:JIANGSU HENGLI CHEM FIBER

Differential-shrinkage cotton-like composite filament and preparation method thereof

ActiveCN104562340AGood flexibilityGood compatibilityOrganic compound preparationAmino-carboxyl compound preparationPolyesterFatty acid ester

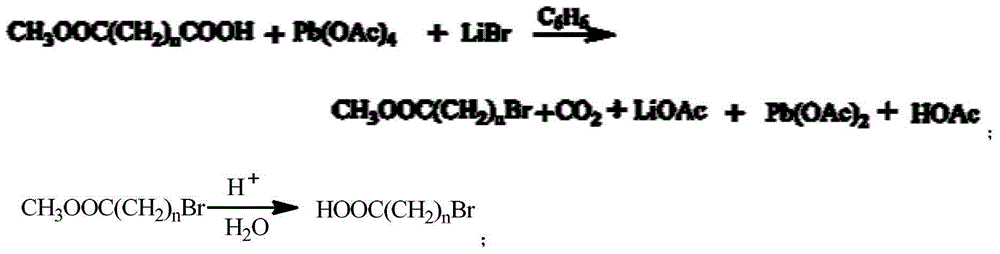

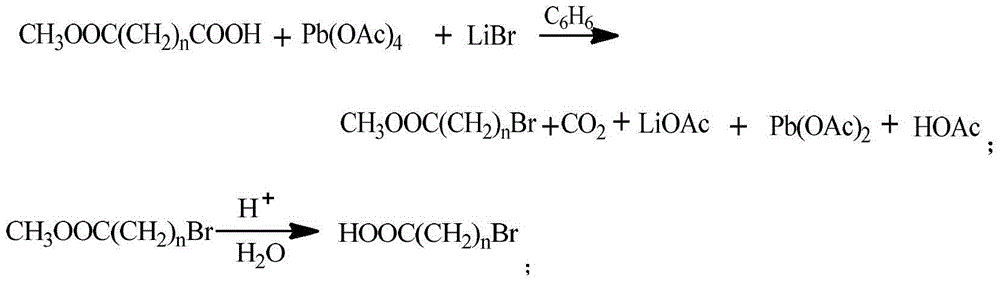

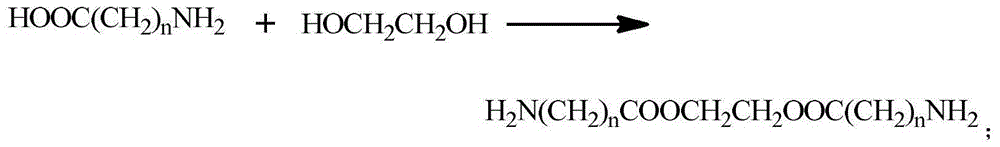

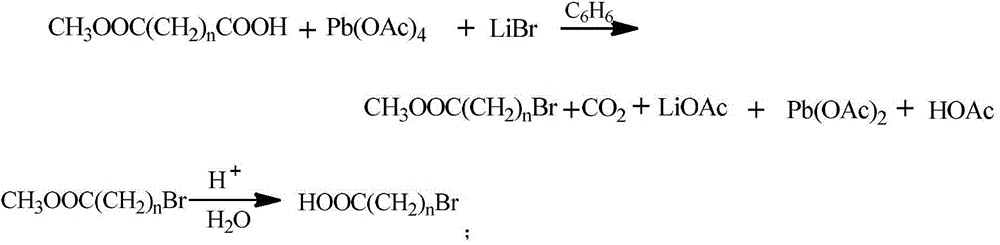

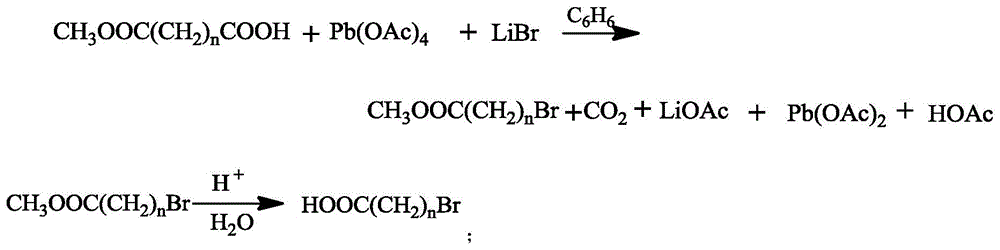

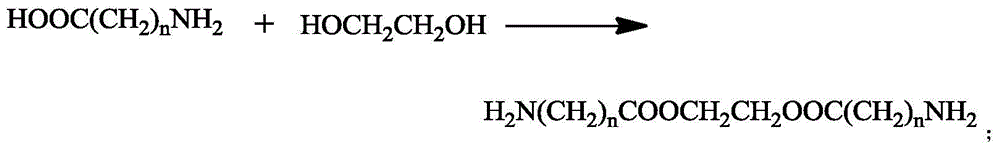

The invention relates to a differential-shrinkage cotton-like composite filament and preparation method thereof; the differential-shrinkage cotton-like composite filament is a composite filament blended by a modified polyester POY filament and a modified polyester FDY filament; the modified polyester consists of polyester and aminoadipic acid glycol ester; the aminoadipic acid glycol ester is dispersed among the molecular chains of the polyester; and the aminoadipic acid glycol ester takes effect of hydrogen bond among the molecular chains of the polyester, so as to stabilize the positions of the aminoadipic acid glycol ester with respect to the molecular chains of the polyester; in condition of the temperature is 90-130 degrees centigrade, the free volume spaces among the molecular chains inside the fiber of the differential-shrinkage cotton-like composite filament are increased by 20-30v / v%. The aliphatic ester increases the free volume of the polyester fiber in order to increase the diffusion degree of the dye, thereby increasing the dyeing performance of the polyester fiber. The differential-shrinkage cotton-like composite filament is applicable to clothes fabric, bedding article, decoration article, and the like.

Owner:JIANGSU HENGLI CHEM FIBER

Linen-like type differential shrinkage composite filament and preparation method thereof

ActiveCN104480568AGood flexibilityGood compatibilityNew-spun product collectionOrganic compound preparationFiberPolyester

The invention relates to a linen-like type differential shrinkage composite filament and a preparation method thereof. The linen-like type differential shrinkage composite filament is a composite filament prepared from modified polyester POY filaments and modified polyester FDY filaments which are subjected to fiber mixing processing; the breakage elongation of the linen-like type differential shrinkage composite filament is 40.0+ / -3.0%, the network degree of the linen-like type differential shrinkage composite filament is 95+ / -5 piece / m; the modified polyester consists of polyester and amino fatty acid gylcol ester; the amino fatty acid gylcol ester is dispersed among the molecular chains of the polyester and has a hydrogen bonding function with the molecular chains of the polyester, so that the relative positions of the amino fatty acid gylcol ester and the molecular chains of the polyester are fixed; under the condition that the temperature is 90-130 DEG C, the free volume space among the molecular chains of fiber of the linen-like type differential shrinkage composite filament is increased by 20-30v / v%. Due to adoption of the aliphatic ester, the free volume of the polyester fiber is increased, so that the diffusion degree of dye is increased, and the dyeing property of the polyester fiber is improved. The linen-like type differential shrinkage composite filament can be used in the industries such as high-class woof fabrics and clothes.

Owner:JIANGSU HENGLI CHEM FIBER

Wool-like differential shrinkage composite filament and preparation method thereof

ActiveCN104480567AGood flexibilityGood compatibilityNew-spun product collectionOrganic compound preparationPolyesterFiber

The invention relates to a wool-like differential shrinkage composite filament and a preparation method thereof. The wool-like differential shrinkage composite filament is a composite filament prepared from modified polyester POY filaments and modified polyester FDY filaments which are subjected to fiber mixing processing; the amino fatty acid gylcol ester is dispersed among the molecular chains of the polyester and has a hydrogen bonding function with the molecular chains of the polyester, so that the relative positions of the amino fatty acid gylcol ester and the molecular chains of the polyester are fixed; under the condition that the temperature is 90-130 DEG C, the free volume space among the molecular chains of fiber of the wool-like differential shrinkage composite filament is increased by 20-30v / v%. Due to adoption of the aliphatic ester, the free volume of the polyester fiber is increased, so that the diffusion degree of dye is increased, and the dyeing property of the polyester fiber is improved. The wool-like differential shrinkage composite filament can be used in the industries such as clothes fabrics, bedding articles and decorative articles.

Owner:JIANGSU HENGLI CHEM FIBER

High-modulus and low-shrinkage type activated polyester industry yarn and preparation method thereof

ActiveCN104499081AIncreased free volumeIncrease polarityNew-spun product collectionMelt spinning methodsPolyesterFiber

The invention relates to a high-modulus and low-shrinkage type activated polyester industry yarn and a preparation method thereof. The high-modulus and low-shrinkage type activated polyester industry yarn is prepared from modified polyester, the modified polyester is composed of polyester and aminoadipic acid gylcol ester, the aminoadipic acid gylcol ester is dispersed among molecular chains of the polyester, hydrogen-bond interaction exists between the aminoadipic acid gylcol ester and the molecular chains of the polyester, and the relative position of the aminoadipic acid gylcol ester and the molecular chains of the polyester is fixed; the free volume space among the molecular chains inside the fibers is increased by 10-15v / v% when the high-modulus and low-shrinkage type activated polyester industry yarn is at 70-80 DEG C, a part of activating agent molecules are dispersed into fiber gaps, more -OHs and -NHs with strong activity are introduced, and the reactivity of the polyester fiber is improved; and the high-modulus and low-shrinkage type activated polyester industry yarn can be applied to light trucks, canvas conveyer belts and the like.

Owner:JIANGSU HENGLI CHEM FIBER

Porous super-bright polyester fiber and preparation method thereof

ActiveCN104532392AGood flexibilityGood compatibilityMonocomponent polyesters artificial filamentArtifical filament manufactureYarnPolyester

Owner:JIANGSU HENGLI CHEM FIBER

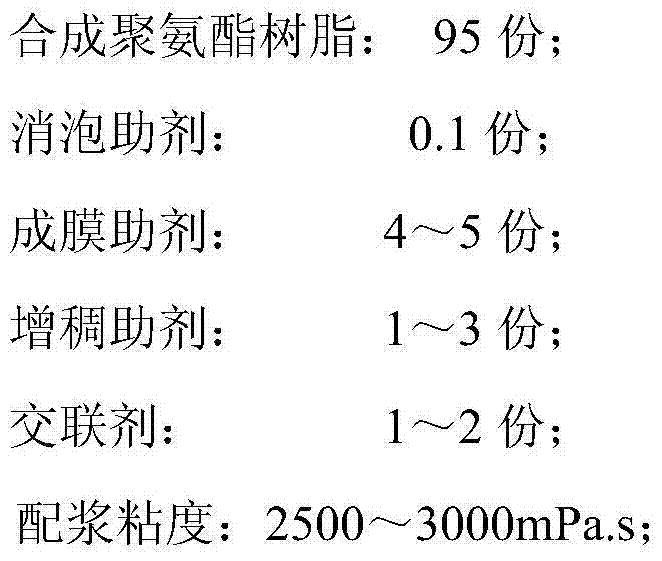

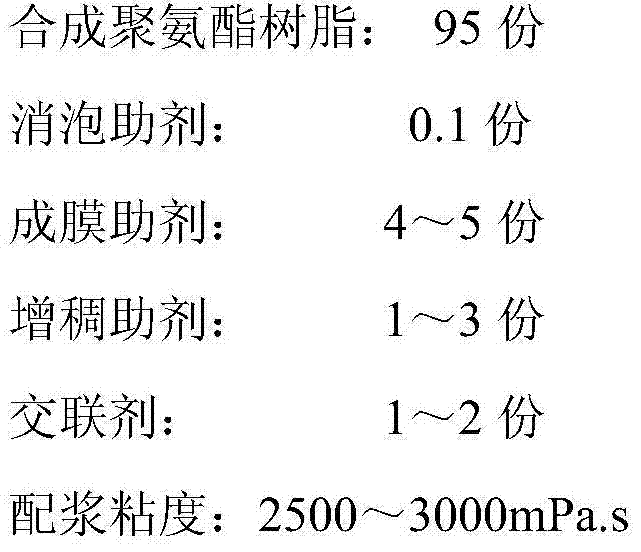

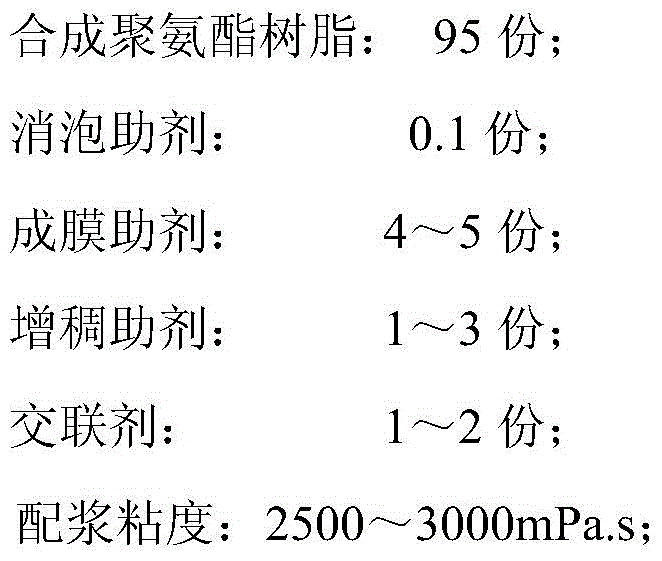

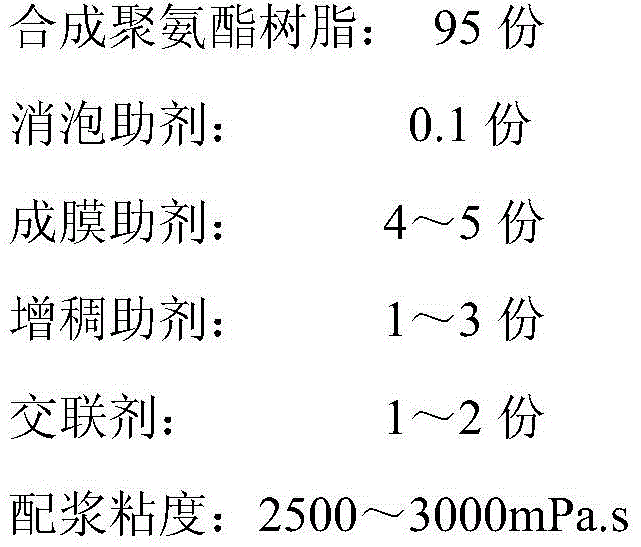

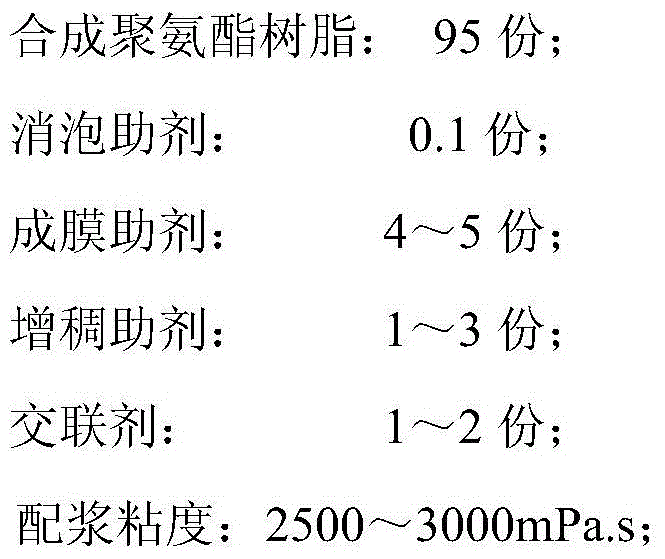

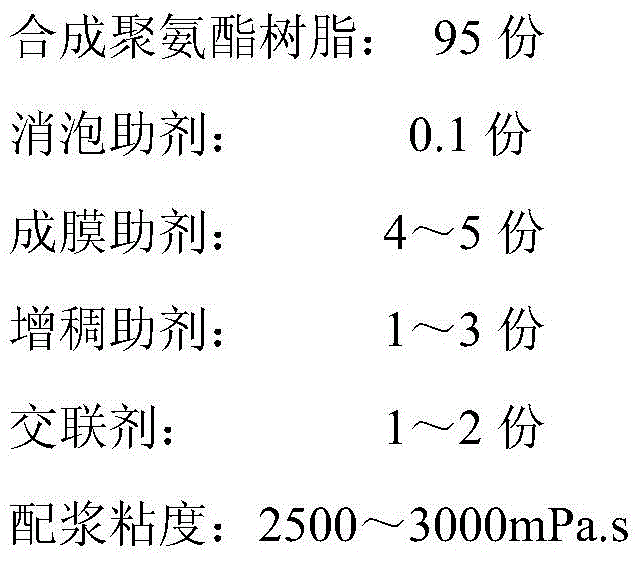

Polyurethane coated fabric and preparation method thereof

ActiveCN104499083AIncreased free volumeImprove efficiencyNew-spun product collectionFibre typesPolyesterYarn

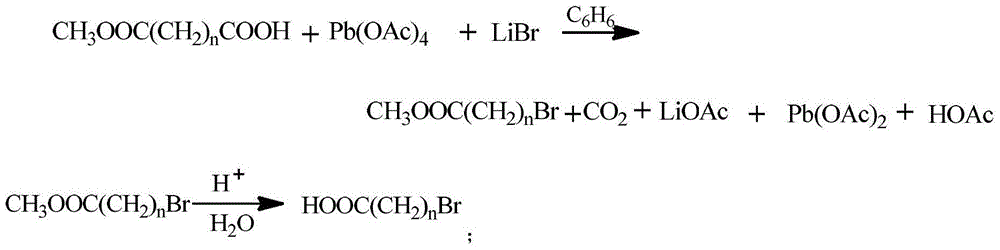

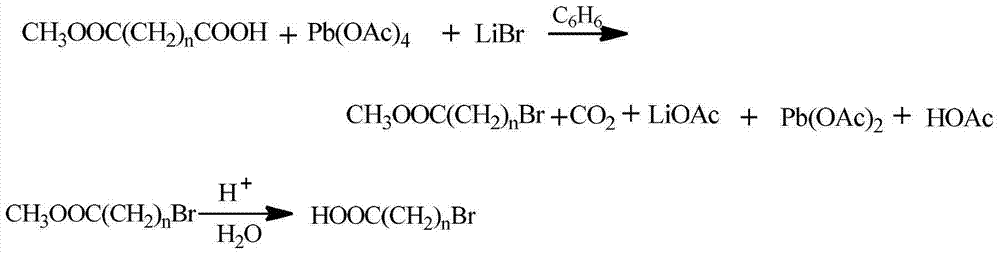

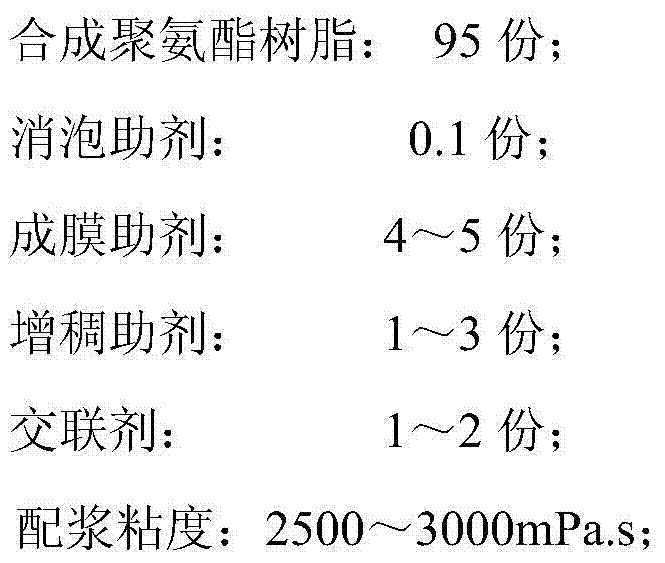

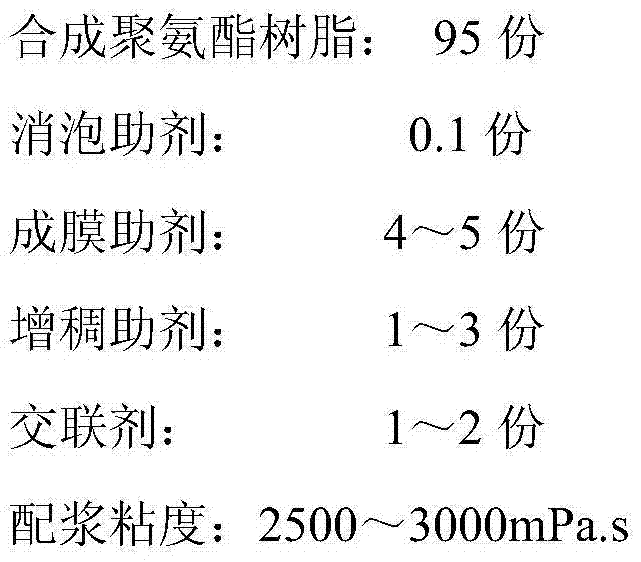

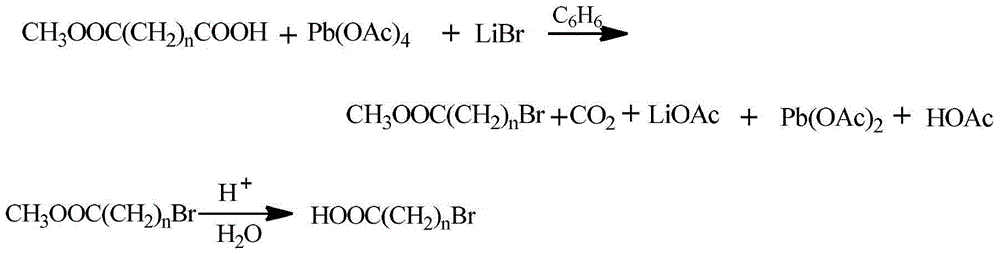

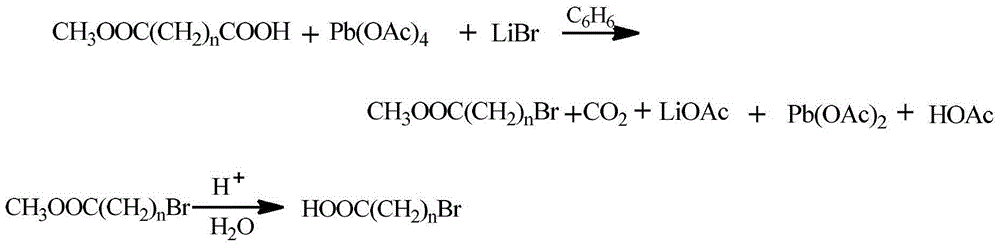

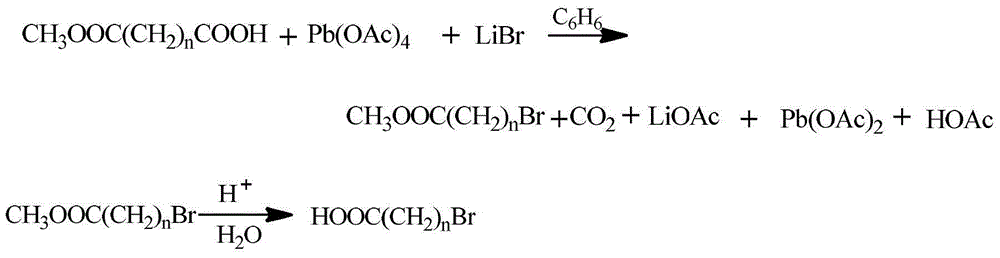

The invention relates to a polyurethane coated fabric and a preparation method thereof. The polyurethane coated fabric comprises a fabric layer and a polyurethane coating, the warps and the wefts of the fabric layer are polyester industry yarns for the polyurethane coated fabric, the polyester industry yarns for the polyurethane coated fabric are made from modified polyester, the modified polyester is composed of polyester and aminoadipic acid gylcol ester, the aminoadipic acid gylcol ester is dispersed among molecular chains of the polyester, hydrogen-bond interaction exists between the aminoadipic acid gylcol ester and the molecular chains of the polyester, and the relative position of the aminoadipic acid gylcol ester and the molecular chains of the polyester is fixed; the free volume space among the molecular chains inside the fiber is increased by 20-40v / v% when the polyester industry yarns for the polyurethane coated fabric are at 100-150 DEG C, the polyurethane coated fabric and the polyurethane have good interface bonding effect, and the polyester industry yarns for the polyurethane coated fabric can be used for improving the appearance of the fabric.

Owner:JIANGSU HENGLI CHEM FIBER

Polyester paralleling composite yarn and prepared method thereof

ActiveCN104499091AGood flexibilityGood compatibilityNew-spun product collectionMelt spinning methodsYarnPolyester

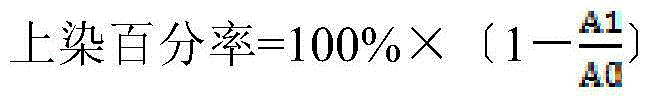

The invention relates to a polyester paralleling composite yarn. The polyester paralleling composite yarn is prepared from PBT (polybutylece terephthalate) and modified polyester PET (polyethylene terephthalate) chips through parallel composite spinning, wherein the modified polyester is composed of polyester and aminoadipic acid gylcol ester, the aminoadipic acid gylcol ester is dispersed among molecular chains of the polyester, hydrogen-bond interaction exists between the aminoadipic acid gylcol ester and the molecular chains of the polyester, and the relative position of the aminoadipic acid gylcol ester and the molecular chains of the polyester is fixed; the free volume space among the molecular chains inside the fibers is increased by 20-30v / v% when the polyester of the polyester paralleling composite yarn is at 90-130 DEG C, the dying rate of the polyester paralleling composite yarn is higher than that of the common fiber when the polyester paralleling composite yarn adopts disperse red 3B and the like, less surface dyeing is formed after dyeing, and the polyester paralleling composite yarn has wide application prospect in the field of garment materials.

Owner:JIANGSU HENGLI CHEM FIBER

Low-shrinkage type activated polyester industrial filament and preparation method thereof

ActiveCN104480563AGood flexibilityGood compatibilityOrganic compound preparationNew-spun product collectionBreaking strengthPolyester

The invention relates to a low-shrinkage type activated polyester industrial filament and a preparation method thereof. The low-shrinkage type activated polyester industrial filament is made of modified polyester; the modified polyester consists of polyester and amino fatty acid gylcol ester; the amino fatty acid gylcol ester is dispersed among molecular chains of the polyester and has hydrogen-bond interaction to the polyester, so that the relative positions of the molecular chain of the amino fatty acid gylcol ester and the polyester are fixed; under the condition of 70-80 DEG C, the free volume space of a part of the molecular chains inside the low-shrinkage type activated polyester industrial filament is increased by 10-15v / v%, the breaking strength of the low-shrinkage type activated polyester industrial filament is greater than or equal to 7.6 cN / dtex, and the core absorption height is less than or equal to 5 mm. A part of molecules of an activating agent are diffused and enter fiber gaps, and more -OH and -NH with relatively high activity are introduced into polyester molecules, so that the reactivity of the polyester fiber is improved. The low-shrinkage type activated polyester industrial filament can be used in apron fabrics, radial tire builder fabrics, and the like.

Owner:JIANGSU HENGLI CHEM FIBER

Polyester elastic yarn and preparation method thereof

ActiveCN104480569AGood flexibilityGood compatibilityOrganic compound preparationFilament/thread formingYarnPolytrimethylene terephthalate

The invention relates to a polyester elastic yarn and a preparation method thereof. The polyester elastic yarn is a double-component parallel composite yarn prepared from PTT (Polytrimethylene Terephthalate) and modified polyester; the elongation at break of the polyester elastic yarn is 30.0+ / -3.0%, and the boiling water shrinkage is 10.0+ / -0.5%; the modified polyester is prepared from polyester and amino fatty acid gylcol ester, wherein the amino fatty acid gylcol ester is dispersed among molecular chains of polyester and is in hydrogen-bond interaction with the molecular chains of polyester, therefore, the relative positions of the amino fatty acid gylcol ester and the molecular chains of polyester can be fixed. According to the polyester elastic yarn, the free volume space among molecular chains in fibers is expanded by 20-30v / v% under a temperature of 90 to 130 DEG C; the dyeing performance of polyester can be improved and the elastic damage degree of composite yarns can be reduced by adopting the polyester elastic yarn; the polyester elastic yarn is suitable for preparing elastic fibers and elastic decorative products.

Owner:JIANGSU HENGLI CHEM FIBER

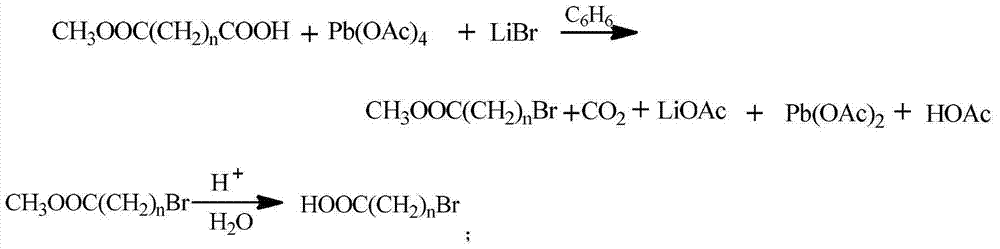

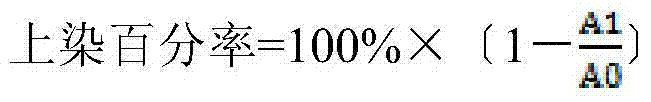

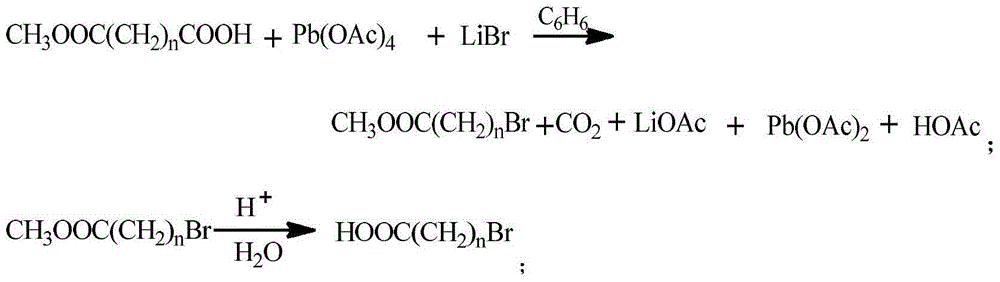

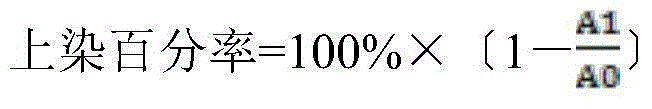

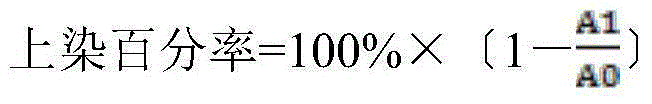

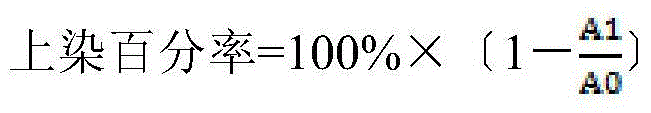

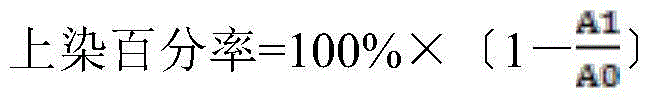

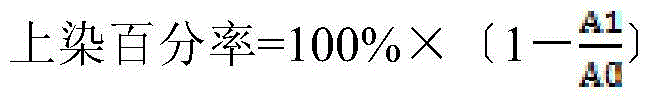

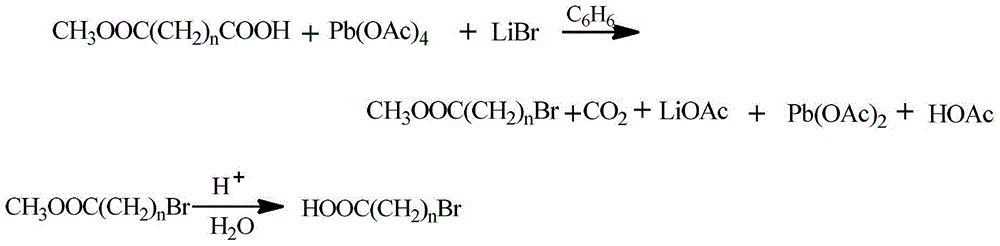

High-dye-uptake polyester fiber POY (partially oriented yarn) and preparation method thereof

ActiveCN104480562AGood flexibilityGood compatibilityOrganic compound preparationMonocomponent copolyesters artificial filamentPolyesterFiber

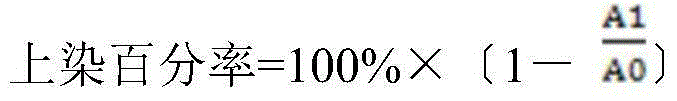

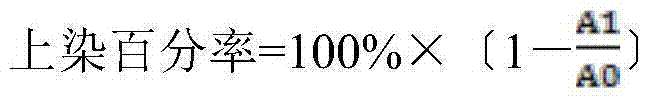

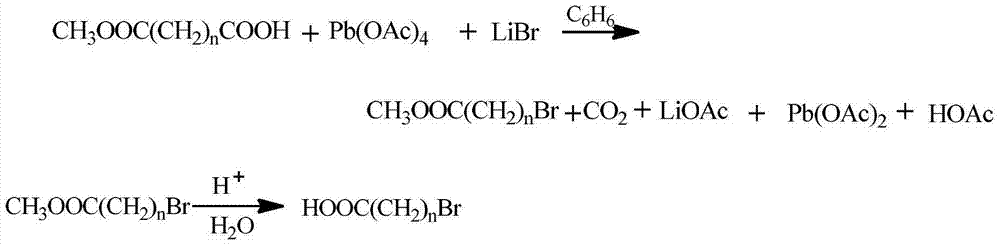

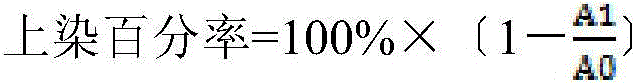

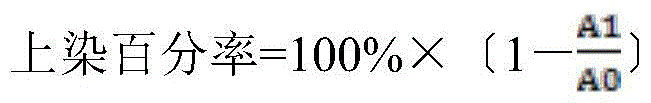

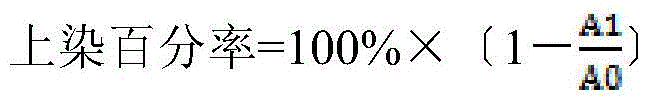

The invention relates to a high-dye-uptake polyester fiber POY (partially oriented yarn) and a preparation method thereof. The material of the high-dye-uptake polyester fiber POY is modified polyester; the modified polyester is prepared from polyester and amino fatty acid glycol ester, the amino fatty acid glycol ester is dispersed among molecular chains of the polyester, and the molecular chains of the amino fatty acid glycol ester and the polyester have hydrogen-bonding interaction, so that the elative positions of the molecular chains of the amino fatty acid glycol ester and the polyester are fixed. According to the high-dye-uptake polyester fiber POY, the free volume of each of intervals among fiber internal molecular chains is increased by 20-30 v / v% at 90-130 DEG C; due to the addition of the fatty acid ester, the free volume of the polyester is increased so as to increase the dispersion degree of dye and improve the dying performance of the polyester. The high-dye-uptake polyester fiber POY can be applied to garment materials, bedding articles, decorative items and the like.

Owner:JIANGSU HENGLI CHEM FIBER

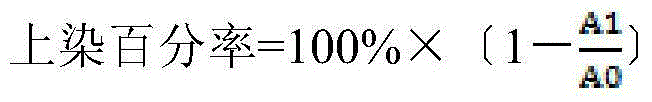

High-dye-uptake-rate polyester fiber and preparation method thereof

ActiveCN104532391AGood flexibilityGood compatibilityMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterFiber

The invention relates to high-dye-uptake-rate polyester fiber and a preparation method thereof. The high-dye-uptake-rate polyester fiber is made from modified polyester. The modified polyester is prepared by polyester and amido fatty acid gylcol ester, wherein the amido fatty acid gylcol ester is dispersed among molecular chains of the polyester to produce mutual hydrogen-bond interaction, so that the relative positions of the amido fatty acid gylcol ester and the molecular chains of the polyester are fixed. The free volume spaces among the molecular chains inside the high-dye-uptake-rate polyester fiber is increased by 20-30v / v% under the condition of temperature of 90-130 DEG C. The high-dye-uptake-rate polyester fiber has higher dye uptake rate compared with common fiber under the situation that the same dyes including disperse red 3B, disperse blue SE2R, disperse bright blue S-GL and the like are adopted, and the dyeing cost is reduced. The high-dye-uptake-rate polyester fiber can be used for c garment materials, bedding articles, decoration articles and the like.

Owner:JIANGSU HENGLI CHEM FIBER

Polyester fiber FDY (Fully Drawn Yarn) with high dyeing rate and preparation method thereof

ActiveCN104499084AImprove dye uptakeGood flexibilityNew-spun product collectionMelt spinning methodsPolyesterYarn

The invention relates to a polyester fiber FDY (Fully Drawn Yarn) with high dyeing rate and a preparation method thereof. The polyester fiber FDY with high dyeing rate is prepared from modified polyester, the modified polyester is composed of polyester and aminoadipic acid gylcol ester, the aminoadipic acid gylcol ester is dispersed among molecular chains of the polyester, hydrogen-bond interaction exists between the aminoadipic acid gylcol ester and the molecular chains of the polyester, and the relative position of the aminoadipic acid gylcol ester and the molecular chains of the polyester is fixed; the free volume space among the molecular chains inside the fiber is increased by 20-30v / v% when the polyester fiber FDY with high dyeing rate is at 90-130 DEG C, the dying rate of the polyester fiber FDY with high dyeing rate is higher than that of the common fiber when the polyester fiber FDY with high dyeing rate adopts the same dyes such as disperse red 3B, disperse blue SE-2R, disperse bright blue S-GL and the like, less surface dyeing is formed after dyeing, and the polyester fiber FDY with high dyeing rate can be used for garment materials, bedding article decoration and the like.

Owner:JIANGSU HENGLI CHEM FIBER

Heavy-caliber conveyer belt

ActiveCN104499292AGood flexibilityGood compatibilityConveyorsOrganic compound preparationPolyesterFiber

The invention relates to a heavy-caliber conveyer belt. The heavy-caliber conveyer belt comprises a fabric layer and a polyurethane coating, the warps and the wefts of the fabric layer are modified polyester industry yarns, the modified polyester industry yarns are prepared from modified polyester, the modified polyester is composed of polyester and aminoadipic acid gylcol ester, the aminoadipic acid gylcol ester is dispersed among molecular chains of the polyester, hydrogen-bond interaction exists between the aminoadipic acid gylcol ester and the molecular chains of the polyester, and the relative position of the aminoadipic acid gylcol ester and the molecular chains of the polyester is fixed; the free volume space among the molecular chains inside the fiber is increased by 20-40v / v% when the modified polyester industry yarns are at 100-150 DEG C, polyurethane can form a firm resinoid coating on the surface of the fabric layer when the modified polyester industry yarn is subjected to heat treatment process, and the polyurethane coated fabric and the polyurethane have good interface bonding effect; and the heavy-caliber conveyer belt is mainly used for delivering high pressure water.

Owner:JIANGSU HENGLI CHEM FIBER

Extra dark shade fabric and preparation method thereof

ActiveCN104480754AGood compatibilityImprove compatibilityOrganic compound preparationFibre typesPolyesterAminal

The invention relates to extra dark shade fabric and a preparation method thereof. The extra dark shade fabric is fabric which is prepared from modified polyester fiber, then dyed by disperse black dye and treated through deepening and active amino silicone oil treatment; the modified polyester fiber fabric is made of modified polyester, and the ratio of opaque body absorption coefficient K and opaque body scattering coefficient S, namely K / S, of the extra dark shade fabric treated through depth-finishing within a wave length of 400 to 700nm is increased greatly; the modified polyester is composed of polyester and amino fatty acid gylcol ester, the amino fatty acid gylcol ester is dispersed among molecular chains of the polyester, and the amino fatty acid gylcol ester and the molecular chains of the polyester are in hydrogen-bond interaction, so that the relative positions of the amino fatty acid gylcol ester and the molecular chains of the polyester are fixed. The extra dark shade fabric can be used for various garment materials and decoration articles.

Owner:JIANGSU HENGLI CHEM FIBER

Conductive fabric and preparation method thereof

ActiveCN104532390AIncreased free volumeEnhanced interface bindingFibre typesMonocomponent polyesters artificial filamentPolyesterFiber

The invention relates to a conductive fabric and a preparation method thereof. The conductive fabric is composed of a modified polyester industrial silk fabric and a copper plating layer coated on the silk fabric. The material of modified polyester industrial yarns is modified polyester, and the modified polyester is composed of polyester and amino fatty acid glycol ester; under a certain temperature condition, the increasing range of free volume of the amino fatty acid glycol ester is much greater than that of polyester macromolecular chain, so that the interfacial combined functions of the metal coating and polyester fibers are improved, and the wash fastness of the metal coating is improved. Meanwhile, the regularity and crystallization of polyester structure are not destroyed, and the good performance of polyester is maintained. The conductive fabric is widely used in the field of clothing, electronic industry, medical science, biological science, aerospace and the like.

Owner:JIANGSU HENGLI CHEM FIBER

Water-repellent fabric and manufacturing method thereof

ActiveCN104532389AIncreased free volumeEnhanced interface bindingFibre typesMonocomponent polyesters artificial filamentBreaking strengthYarn

The invention relates to water-repellent fabric and a manufacturing method of the water-repellent fabric. The water-repellent fabric is formed by weaving polyester industrial yarn used for the water-repellent fabric, the polyester industrial yarn used for the water-repellant fabric is made of modified polyester, and the water-repellant fabric is formed by arranging after water repellency. The modified polyester is composed of polyester and amino fatty acid glycol ester dispersed among molecular chains of the polyester, a hydrogen-bond interaction is achieved between the amino fatty acid glycol ester and the molecular chains of the polyester, and therefore the relative positions of the amino fatty acid glycol ester and the molecular chains of the polyester are fixed. According to the water-repellent fabric, at the temperature of 70 DEG C-130 DEG C, the free volume space between the molecular chains inside fibers is enlarged by 10 v / v%-30 v / v%, the breaking strength of the polyester industrial yarn used for the water-repellant fabric is larger than or equal to 7.2 cN / dtex, and the elongation at break is 20.0+ / -2.0%. The washable performance of the water-repellant fabric is good. The water-repellant fabric can be used for industries such as tents and drapes.

Owner:JIANGSU HENGLI CHEM FIBER

A kind of polyester side-by-side composite yarn and preparation method thereof

ActiveCN104499091BGood flexibilityGood compatibilityNew-spun product collectionMelt spinning methodsYarnPolyethylene terephthalate

The invention relates to a polyester paralleling composite yarn. The polyester paralleling composite yarn is prepared from PBT (polybutylece terephthalate) and modified polyester PET (polyethylene terephthalate) chips through parallel composite spinning, wherein the modified polyester is composed of polyester and aminoadipic acid gylcol ester, the aminoadipic acid gylcol ester is dispersed among molecular chains of the polyester, hydrogen-bond interaction exists between the aminoadipic acid gylcol ester and the molecular chains of the polyester, and the relative position of the aminoadipic acid gylcol ester and the molecular chains of the polyester is fixed; the free volume space among the molecular chains inside the fibers is increased by 20-30v / v% when the polyester of the polyester paralleling composite yarn is at 90-130 DEG C, the dying rate of the polyester paralleling composite yarn is higher than that of the common fiber when the polyester paralleling composite yarn adopts disperse red 3B and the like, less surface dyeing is formed after dyeing, and the polyester paralleling composite yarn has wide application prospect in the field of garment materials.

Owner:JIANGSU HENGLI CHEM FIBER

A kind of high dye uptake polyester fiber fdy yarn and preparation method thereof

ActiveCN104499084BImprove dye uptakeGood flexibilityNew-spun product collectionMelt spinning methodsYarnFiber

Owner:JIANGSU HENGLI CHEM FIBER

A kind of ultra-bright three-lobed special-shaped FDY fiber and its preparation method

ActiveCN104480564BGood flexibilityGood compatibilityOrganic compound preparationFilament/thread formingFiberPolyester

The invention relates to super-bright light trefoil irregular FDY fiber and a preparation method thereof. The super-bright light trefoil irregular FDY fiber is made of modified polyester and is manufactured by spinning the modified polyester by using a trefoil irregular spinneret plate of which the spinneret orifice has a Y-shaped structure; the modified polyester consists of polyester and amino fatty acid gylcol ester; the amino fatty acid gylcol ester is dispersed among molecular chains of the polyester and has hydrogen-bond interaction to the polyester, so that the relative positions of the molecular chains of the amino fatty acid gylcol ester and the polyester are fixed; under the condition of 90-130 DEG C, the free volume space of a part of the molecular chains inside the super-bright light trefoil irregular FDY fiber is increased by 20-30v / v%. Under the condition that identical pigment such as disperse red 3B is used, the super-bright light trefoil irregular FDY fiber has a dyeing rate which is much higher than that of ordinary fiber, and color flooding is reduced after dyeing. The super-bright light trefoil irregular FDY fiber can be used in fields such as woven satin fabrics and imitated silk fabrics.

Owner:JIANGSU HENGLI CHEM FIBER

A kind of hemp-like different shrinkage composite yarn and its preparation method

ActiveCN104480568BGood flexibilityGood compatibilityOrganic compound preparationNew-spun product collectionFiberPolyester

The invention relates to a linen-like type differential shrinkage composite filament and a preparation method thereof. The linen-like type differential shrinkage composite filament is a composite filament prepared from modified polyester POY filaments and modified polyester FDY filaments which are subjected to fiber mixing processing; the breakage elongation of the linen-like type differential shrinkage composite filament is 40.0+ / -3.0%, the network degree of the linen-like type differential shrinkage composite filament is 95+ / -5 piece / m; the modified polyester consists of polyester and amino fatty acid gylcol ester; the amino fatty acid gylcol ester is dispersed among the molecular chains of the polyester and has a hydrogen bonding function with the molecular chains of the polyester, so that the relative positions of the amino fatty acid gylcol ester and the molecular chains of the polyester are fixed; under the condition that the temperature is 90-130 DEG C, the free volume space among the molecular chains of fiber of the linen-like type differential shrinkage composite filament is increased by 20-30v / v%. Due to adoption of the aliphatic ester, the free volume of the polyester fiber is increased, so that the diffusion degree of dye is increased, and the dyeing property of the polyester fiber is improved. The linen-like type differential shrinkage composite filament can be used in the industries such as high-class woof fabrics and clothes.

Owner:JIANGSU HENGLI CHEM FIBER

A kind of polyurethane coating fabric and preparation method thereof

ActiveCN104499083BGood flexibilityGood compatibilityNew-spun product collectionFibre typesYarnPolyester

The invention relates to a polyurethane-coated fabric and a preparation method thereof. The polyurethane-coated fabric includes a fabric layer and a polyurethane coating. The warp and weft lines of the fabric layer are polyester industrial yarns for polyurethane-coated fabrics. The polyurethane-coated fabric The material of polyester industrial yarn for layer fabric is modified polyester. The modified polyester is composed of polyester and amino fatty acid glycol ester. The amino fatty acid glycol ester is dispersed in the molecular chain of the polyester. between, and there is a hydrogen bonding effect between the amino fatty acid ethylene glycol ester and the molecular chain of the polyester, so that the relative positions of the amino fatty acid ethylene glycol ester and the molecular chain of the polyester are fixed; the polyurethane When the polyester industrial yarn for coated fabrics has a temperature of 100-150°C, the free volume space between the molecular chains within the fiber increases by 20-40v / v%; the polyurethane-coated fabric has good interface bonding with polyurethane; so The polyester industrial yarn for polyurethane coated fabrics can be used to improve the appearance of fabrics.

Owner:JIANGSU HENGLI CHEM FIBER

A kind of high dye uptake polyester fiber and preparation method thereof

ActiveCN104532391BGood flexibilityGood compatibilityMonocomponent polyesters artificial filamentArtifical filament manufactureFiberPolyester

The invention relates to high-dye-uptake-rate polyester fiber and a preparation method thereof. The high-dye-uptake-rate polyester fiber is made from modified polyester. The modified polyester is prepared by polyester and amido fatty acid gylcol ester, wherein the amido fatty acid gylcol ester is dispersed among molecular chains of the polyester to produce mutual hydrogen-bond interaction, so that the relative positions of the amido fatty acid gylcol ester and the molecular chains of the polyester are fixed. The free volume spaces among the molecular chains inside the high-dye-uptake-rate polyester fiber is increased by 20-30v / v% under the condition of temperature of 90-130 DEG C. The high-dye-uptake-rate polyester fiber has higher dye uptake rate compared with common fiber under the situation that the same dyes including disperse red 3B, disperse blue SE2R, disperse bright blue S-GL and the like are adopted, and the dyeing cost is reduced. The high-dye-uptake-rate polyester fiber can be used for c garment materials, bedding articles, decoration articles and the like.

Owner:JIANGSU HENGLI CHEM FIBER

A kind of wool-like different shrinkage composite yarn and its preparation method

ActiveCN104480567BGood flexibilityGood compatibilityOrganic compound preparationNew-spun product collectionPolyesterFiber

The invention relates to a wool-like differential shrinkage composite filament and a preparation method thereof. The wool-like differential shrinkage composite filament is a composite filament prepared from modified polyester POY filaments and modified polyester FDY filaments which are subjected to fiber mixing processing; the amino fatty acid gylcol ester is dispersed among the molecular chains of the polyester and has a hydrogen bonding function with the molecular chains of the polyester, so that the relative positions of the amino fatty acid gylcol ester and the molecular chains of the polyester are fixed; under the condition that the temperature is 90-130 DEG C, the free volume space among the molecular chains of fiber of the wool-like differential shrinkage composite filament is increased by 20-30v / v%. Due to adoption of the aliphatic ester, the free volume of the polyester fiber is increased, so that the diffusion degree of dye is increased, and the dyeing property of the polyester fiber is improved. The wool-like differential shrinkage composite filament can be used in the industries such as clothes fabrics, bedding articles and decorative articles.

Owner:JIANGSU HENGLI CHEM FIBER

A large diameter conveyor belt

ActiveCN104499292BGood flexibilityGood compatibilityConveyorsNew-spun product collectionYarnPolyester

The invention relates to a heavy-caliber conveyer belt. The heavy-caliber conveyer belt comprises a fabric layer and a polyurethane coating, the warps and the wefts of the fabric layer are modified polyester industry yarns, the modified polyester industry yarns are prepared from modified polyester, the modified polyester is composed of polyester and aminoadipic acid gylcol ester, the aminoadipic acid gylcol ester is dispersed among molecular chains of the polyester, hydrogen-bond interaction exists between the aminoadipic acid gylcol ester and the molecular chains of the polyester, and the relative position of the aminoadipic acid gylcol ester and the molecular chains of the polyester is fixed; the free volume space among the molecular chains inside the fiber is increased by 20-40v / v% when the modified polyester industry yarns are at 100-150 DEG C, polyurethane can form a firm resinoid coating on the surface of the fabric layer when the modified polyester industry yarn is subjected to heat treatment process, and the polyurethane coated fabric and the polyurethane have good interface bonding effect; and the heavy-caliber conveyer belt is mainly used for delivering high pressure water.

Owner:JIANGSU HENGLI CHEM FIBER

A kind of high dye uptake polyester fiber dty yarn and preparation method thereof

ActiveCN104499082BImprove dye uptakeGood flexibilityNew-spun product collectionMelt spinning methodsFiberPolyester

The invention relates to a polyester fiber DTY (draw textured yarn) with high dyeing rate and a preparation method thereof. The polyester fiber polyester fiber DTY with high dyeing rate is made from modified polyester, the modified polyester is composed of polyester and aminoadipic acid gylcol ester, the aminoadipic acid gylcol ester is dispersed among molecular chains of the polyester, hydrogen-bond interaction exists between the aminoadipic acid gylcol ester and the molecular chains of the polyester, and the relative position of the aminoadipic acid gylcol ester and the molecular chains of the polyester is fixed; the free volume space among the molecular chains inside the fiber is increased by 20-30v / v% when the polyester fiber DTY with high dyeing rate is at 90-130 DEG C, the dying rate of the polyester fiber DTY with high dyeing rate is higher than that of the common fiber when the polyester fiber DTY with high dyeing rate adopts the same dyes such as disperse red 3B, disperse blue SE-2R, disperse bright blue S-GL and the like, less surface dyeing is formed after dyeing, and the polyester fiber DTY with high dyeing rate can be used for garment materials, bedding article decoration and the like.

Owner:JIANGSU HENGLI CHEM FIBER

A kind of ultra-low shrinkage water-repellent polyester industrial yarn and its preparation method

ActiveCN104562694BGood flexibilityGood compatibilityOrganic compound preparationFibre treatmentPolyesterYarn

The invention relates to a super-low-shrinkage water-repellent polyester industrial yarn and a preparation method thereof. The super-low-shrinkage water-repellent polyester industrial yarn is prepared by modified polyester spinning. By the use of the characteristic that at a certain temperature, the increasing amplitude of the free volume of an aminoadipic acid gylcol ester is much larger than that of a polyester macromolecular chain, the interface bonding performance between an organic fluorine water-repellent and oil-repellent finishing agent and polyester fiber is improved; meanwhile, since an amino group is positioned at the initiating end of an aminoadipic acid gylcol ester molecule, the hydrogen-bond interaction between the aminoadipic acid gylcol ester molecule and the polyester macromolecular chain is increased, and the migration is reduced to the most extent. The damage to the regularity and the crystallinity of a polyester structure is avoided, and the excellent performance of the polyester is remained; the wicking height of the super-low-shrinkage water-repellent polyester industrial yarn is smaller than or equal to 0.8 mm. The super-low-shrinkage water-repellent polyester industrial yarn can be used for water-repellent and oil-repellent places needed by industrial textiles.

Owner:JIANGSU HENGLI CHEM FIBER

A kind of cotton-like different shrinkage composite yarn and its preparation method

ActiveCN104562340BGood flexibilityGood compatibilityOrganic compound preparationAmino-carboxyl compound preparationPolyesterFiber

Owner:JIANGSU HENGLI CHEM FIBER

A high-modulus low-shrinkage activated polyester industrial yarn and its preparation method

ActiveCN104499081BGood flexibilityGood compatibilityNew-spun product collectionMelt spinning methodsPolyesterFiber

The invention relates to a high-modulus and low-shrinkage type activated polyester industry yarn and a preparation method thereof. The high-modulus and low-shrinkage type activated polyester industry yarn is prepared from modified polyester, the modified polyester is composed of polyester and aminoadipic acid gylcol ester, the aminoadipic acid gylcol ester is dispersed among molecular chains of the polyester, hydrogen-bond interaction exists between the aminoadipic acid gylcol ester and the molecular chains of the polyester, and the relative position of the aminoadipic acid gylcol ester and the molecular chains of the polyester is fixed; the free volume space among the molecular chains inside the fibers is increased by 10-15v / v% when the high-modulus and low-shrinkage type activated polyester industry yarn is at 70-80 DEG C, a part of activating agent molecules are dispersed into fiber gaps, more -OHs and -NHs with strong activity are introduced, and the reactivity of the polyester fiber is improved; and the high-modulus and low-shrinkage type activated polyester industry yarn can be applied to light trucks, canvas conveyer belts and the like.

Owner:JIANGSU HENGLI CHEM FIBER

A kind of special black fabric and preparation method thereof

ActiveCN104480754BGood flexibilityGood compatibilityOrganic compound preparationFibre typesFiberPolyester

The invention relates to extra dark shade fabric and a preparation method thereof. The extra dark shade fabric is fabric which is prepared from modified polyester fiber, then dyed by disperse black dye and treated through deepening and active amino silicone oil treatment; the modified polyester fiber fabric is made of modified polyester, and the ratio of opaque body absorption coefficient K and opaque body scattering coefficient S, namely K / S, of the extra dark shade fabric treated through depth-finishing within a wave length of 400 to 700nm is increased greatly; the modified polyester is composed of polyester and amino fatty acid gylcol ester, the amino fatty acid gylcol ester is dispersed among molecular chains of the polyester, and the amino fatty acid gylcol ester and the molecular chains of the polyester are in hydrogen-bond interaction, so that the relative positions of the amino fatty acid gylcol ester and the molecular chains of the polyester are fixed. The extra dark shade fabric can be used for various garment materials and decoration articles.

Owner:JIANGSU HENGLI CHEM FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com