Technological method for adjusting barrier height of Schottky diode by doping silicon dioxide film

A technology of Schottky diodes and silicon dioxide films, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of difficult control of injection uniformity and process repeatability, and few scale applications, so as to achieve centralized distribution , reduce the barrier height, the effect of uniform distribution of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

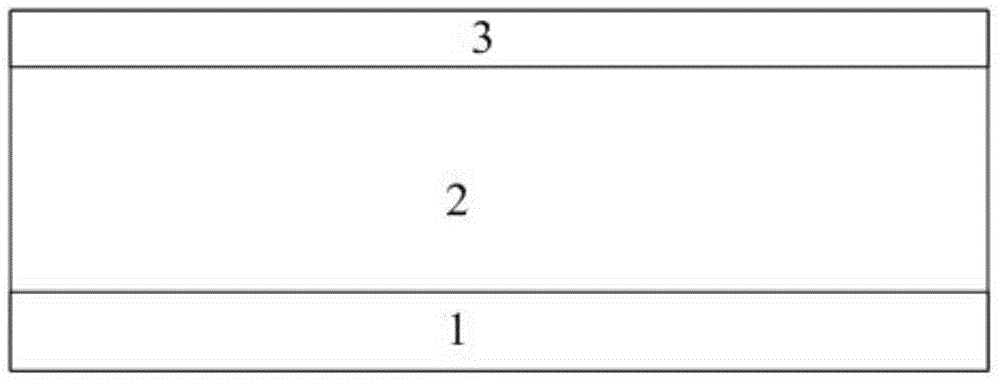

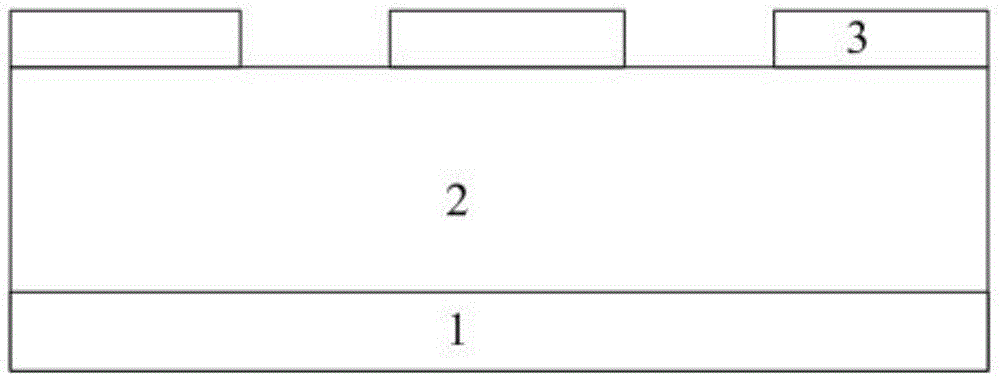

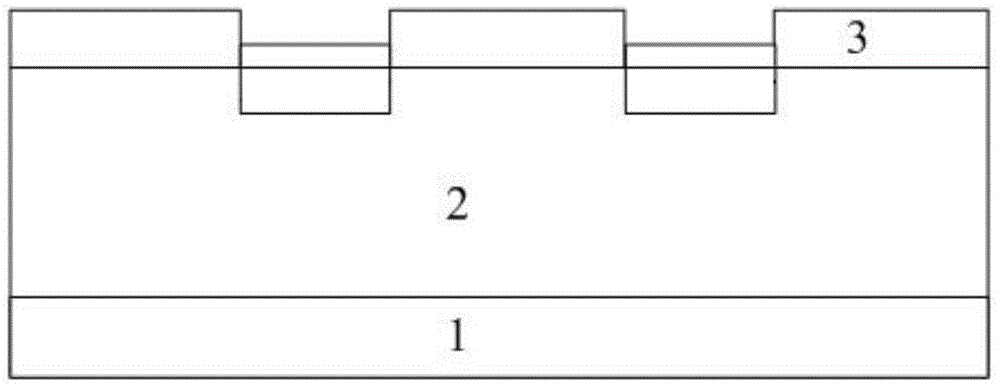

[0023] The process method of adjusting the barrier height of the Schottky diode by doping the silicon dioxide film is made of an N-type single crystal silicon substrate and an N-type single crystal silicon epitaxial layer substrate, and the N-type single crystal on the substrate An oxide layer is formed on the silicon epitaxial layer as a passivation layer, and the thickness of the oxide layer is greater than 400 nanometers; a photolithography and selective etching remove the excess oxide layer to form a doping window; the ion implantation process is used to perform boron doping in the doping window, and at the same time Growth film oxide layer in the doping window forms a P-type protection ring; secondary photolithography and selective etching remove excess oxide layer to form the main surface of the Schottky barrier window; deposit on the main surface of the Schottky barrier window to form a surface The oxide layer of doped silicon dioxide film, the thickness is 50-300 nanome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com