Preparation method of low-temperature polycrystalline silicon film, TFT, array base plate and display device

A low-temperature polysilicon, amorphous silicon thin film technology, applied in transistors, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as reducing overall electrical performance, unstable threshold voltage, and increasing leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

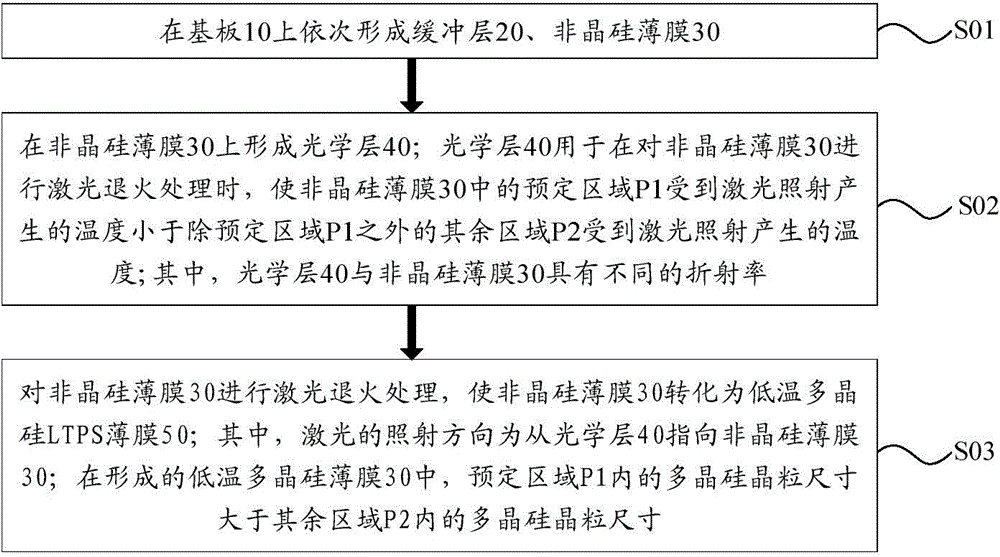

[0035] The embodiment of the present invention provides a method for preparing a low-temperature polysilicon thin film, such as figure 1 As shown, the method includes:

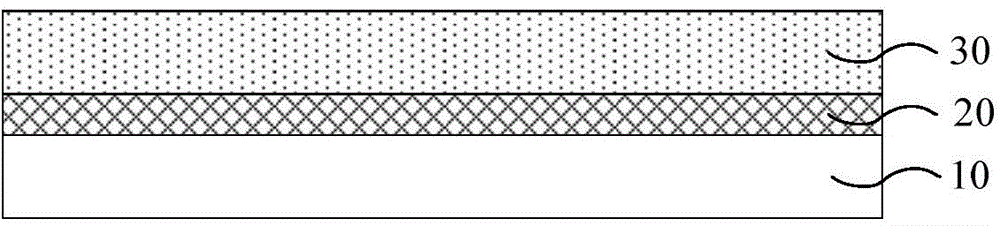

[0036] S01, such as figure 2As shown, a buffer layer 20 and an amorphous silicon thin film 30 are sequentially formed on a substrate 10 .

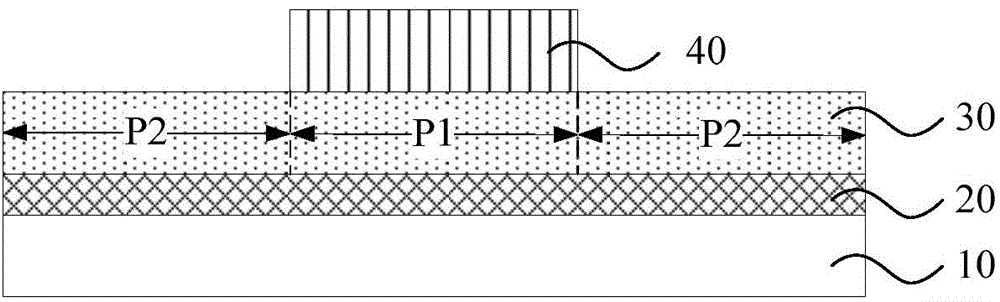

[0037] S02, such as Figure 3A or Figure 3B As shown, an optical layer 40 is formed on the amorphous silicon film 30; the optical layer 40 is used to make the predetermined region in the amorphous silicon film 30 Marked as P1) the temperature produced by laser irradiation is lower than the temperature produced by the rest of the region (marked as P2 in the figure and hereinafter) except the predetermined region P1 by laser irradiation; wherein, the optical layer 40 and the amorphous silicon film 30 have a different refractive indices.

[0038] S03, such as Figure 4A or Figure 4B As shown, the amorphous silicon film 30 is subjected to laser annealing treatment, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com