Epitaxy structure of InGaN quantum dot and growth method

An epitaxial structure and epitaxial growth technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problem of restricting the development and application of InGaN quantum dot devices, difficult to obtain high density, high uniformity and high quality InGaN quantum dot materials, Limiting the density of InGaN quantum dots and other issues to achieve the effect of improving device performance, increasing areal density, and reducing threshold current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

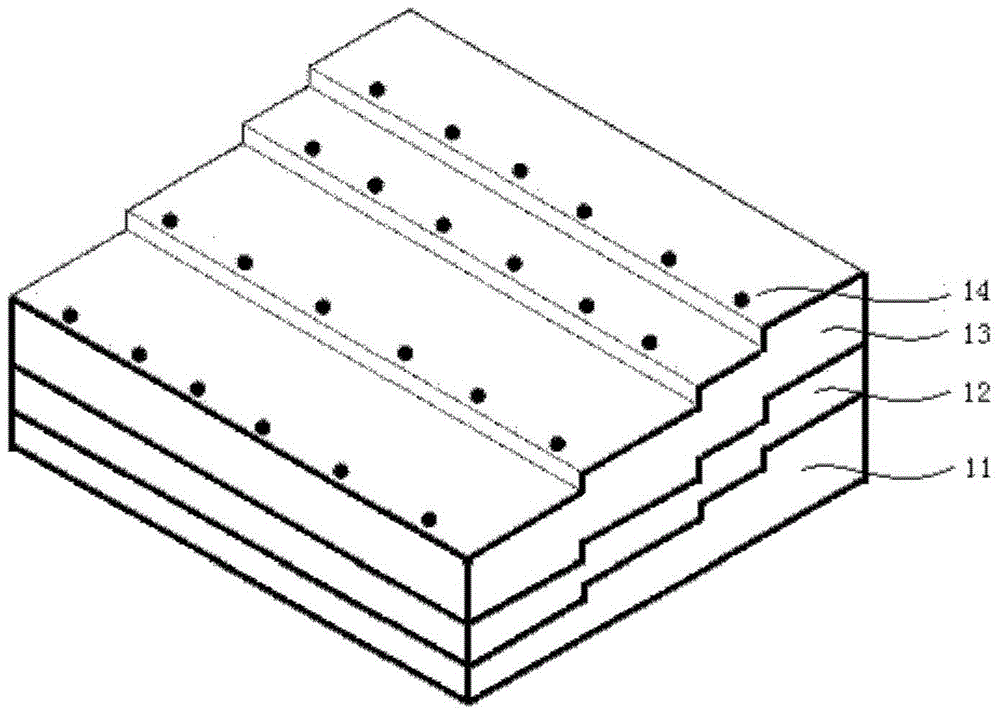

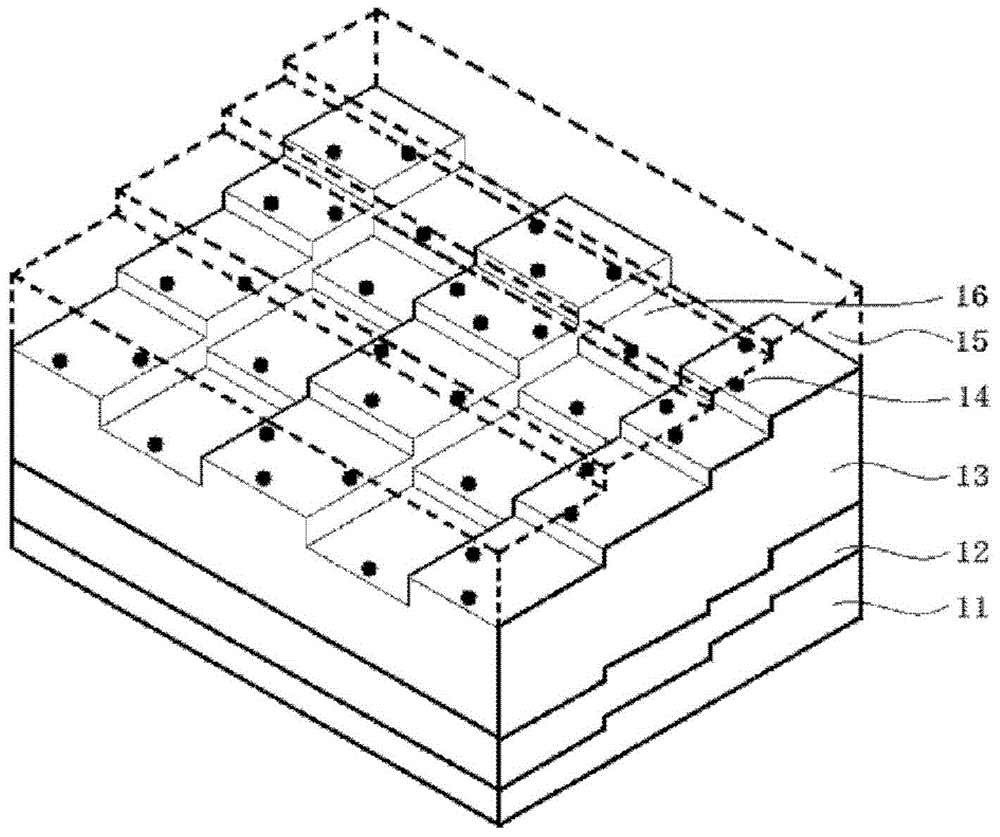

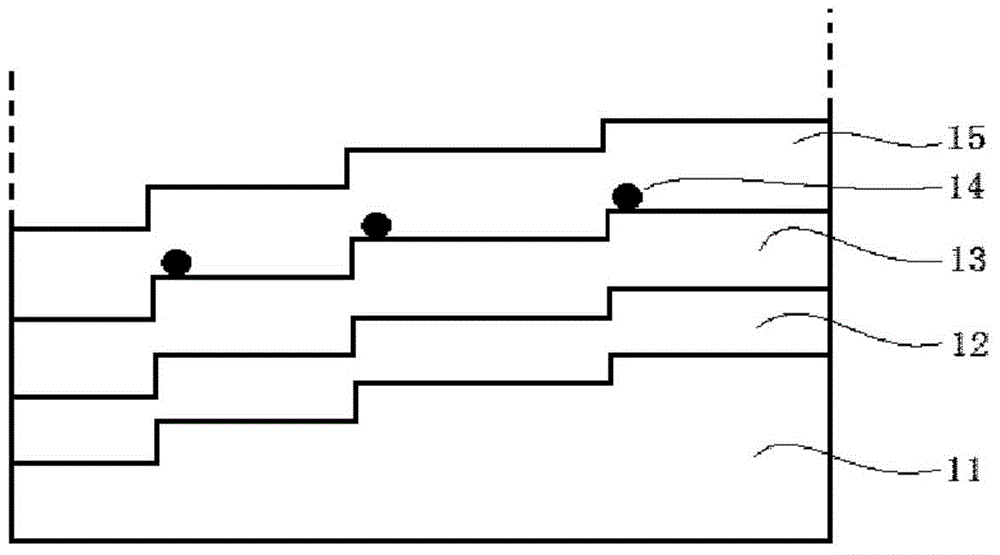

[0029] see figure 2 and image 3 As shown, the epitaxial structure of the InGaN quantum dot provided by the present invention includes:

[0030] A substrate 11, the surface of the substrate 11 has atomic-level step topography, and the bevel angle of the steps is 0.05°-10°. Its material is sapphire, gallium nitride, silicon, silicon carbide or gallium arsenide;

[0031] A low-temperature GaN buffer layer 12 is grown on the substrate 11 . The low-temperature GaN buffer layer 12 has a thickness less than 50 nm and its surface has the same step morphology as that of the substrate 11;

[0032] A high-temperature GaN layer 13 is grown on the low-temperature GaN buffer layer 12 . On its surface, along the direction perpendicular to the steps, uniformly arranged grooves 16 with a depth of 1-100 nm, a width of 10-1000 nm, and a pitch of 0.1-100 μm are etched, so that the surface of the high-temperature GaN layer 13 is staggered and stepped. morphology and form a grid-like structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com