Silver particle ink, silver particle sintered body and method for manufacturing silver particle ink

A manufacturing method and technology of silver particles, which are applied in cable/conductor manufacturing, ink, printed circuit manufacturing, etc., can solve the problems of undisclosed sintering temperature and undisclosed surface roughness of sintered body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0054] Examples of the present invention will be specifically described below.

[0055] Silver particle inks described in the examples were produced in the following manner.

[0056] In the first process, N,N-dimethyl-1,3-diaminopropane is mixed with silver oxalate wetted by 30-200 wt% organic solvent to form N,N-dimethyl -1,3-diaminopropane coordination silver complex. In the second step, hexylamine (6 carbon atoms) and dodecylamine (12 carbon atoms) and oleic acid (19 carbon atoms) as a fatty acid are added to the mixture of the first step and kneaded.

[0057] Specifically, in the first step, silver oxalate is synthesized from silver nitrate and oxalic acid dihydrate, and an organic solvent is added thereto. In this example, the alkylamine was added so that the molar amount of all the alkylamines was approximately 4 to 6 times the molar amount of the silver oxalate. Since there are two silver atoms in the silver oxalate molecule, the amount of the above-mentioned alkylam...

experiment example

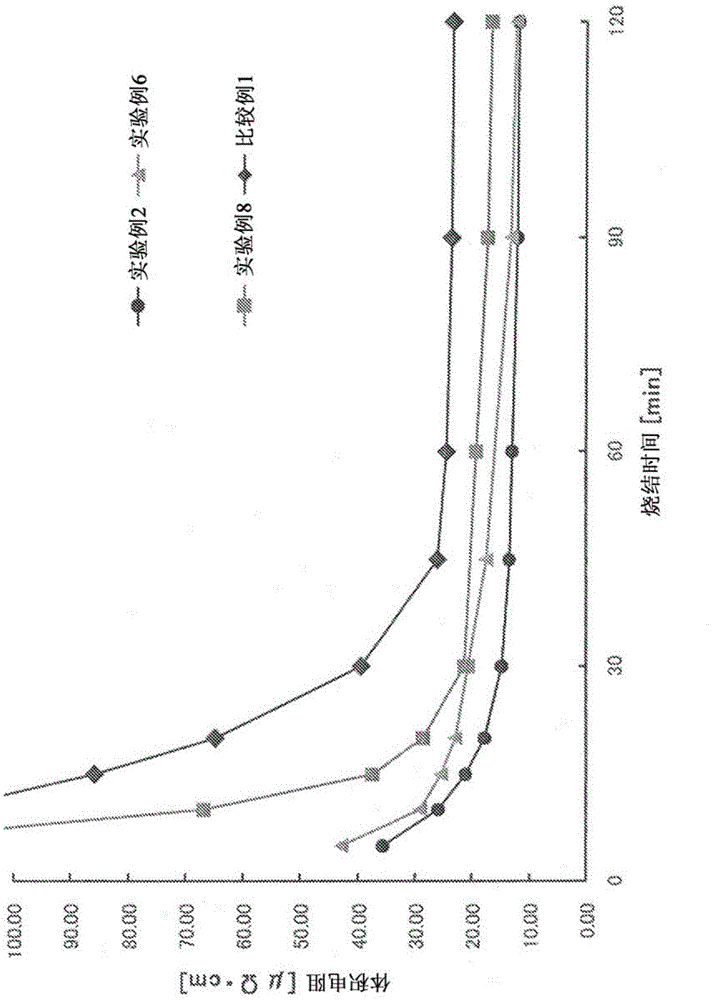

[0069] Table 1 shows Experimental Examples 1 to 15. In addition, Comparative Examples 1-8 are shown in Table 2.

[0070]

[0071]

[0072] Experimental Examples 1 to 8 and Comparative Examples 2 to 4 investigated the wetting by various organic solvents, Comparative Example 1 was not wetted, and Experimental Examples 9 to 12 and Comparative Example 8 investigated the types of organic solvents finally dispersed. In Experimental Examples 13-15 and Comparative Examples 5-7, the addition amount of N,N-dimethyl-1,3-diaminopropane, hexylamine, dodecylamine, and oleic acid relative to silver oxalate was studied, and A silver particle ink was prepared.

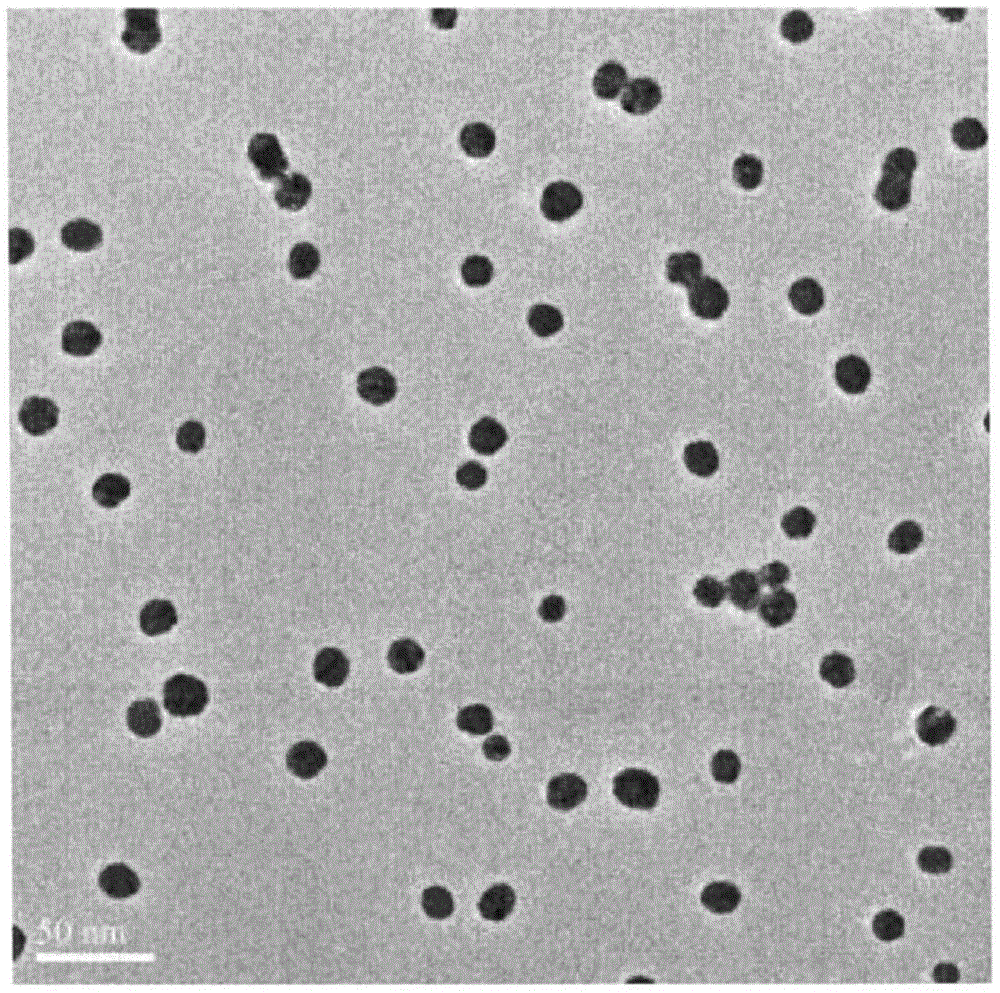

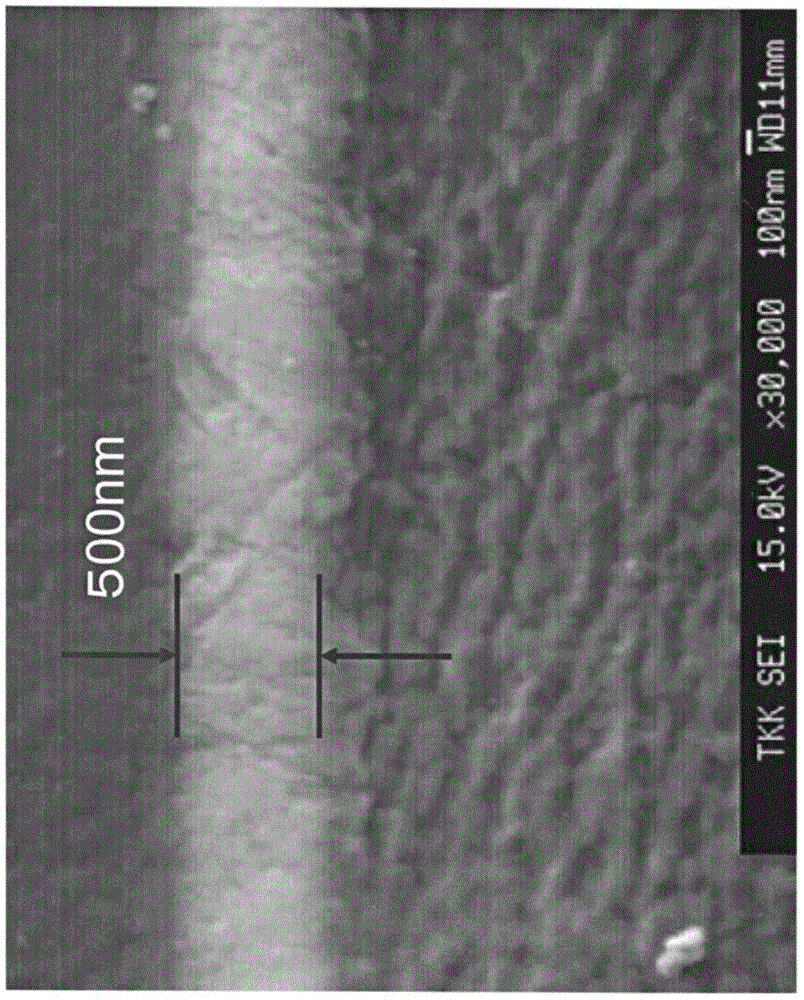

[0073] In Experimental Examples 1 to 15, silver particle inks could be synthesized, and they were stable inks that did not form precipitation for more than one month. On the other hand, in Comparative Example 2, the synthesis of silver fine particles could not be achieved, and no ink was obtained. In addition, in Comparative E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Volume resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com