Pesticide with low irritation and high efficiency and preparation method thereof

A production method and irritating technology, applied in the field of pesticides, can solve the problems of low biological activity, etc., and achieve the effects of reducing potential impact, improving safety, and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

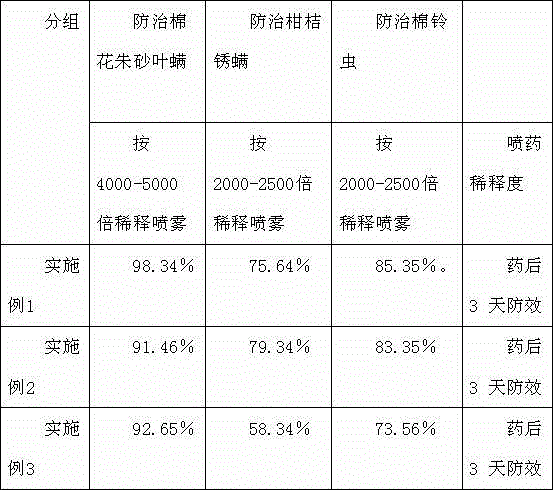

Examples

Embodiment 1

[0020] Benzoate 6%, Abamectin 4%, Emamectin Benzoate 2%, Sucrose 20%, Sodium Lauryl Sulfate 6%, Sodium N-Methyl N-Oleoyl Taurate 8%, polysiloxane 5%, alkylphenol ethoxylate 0.6%, acetophenone 0.5%, kaolin 13%, fatty alcohol ethoxylate 0.4% in a 60 liter portable blender dry blending activity Components benzoate and other raw materials, followed by about 15% by weight of water; the wet mass was then transferred to a basket extruder fitted with a 1.0 mm screen; each batch was divided into two smaller batches, The extrudate was dried on a fluidized bed dryer for 13-15 minutes with an inlet temperature of 60°C and an air flow of 1 m / min. And dry in a single drying cycle, no additional stirring is required in the drying cycle; under vacuum conditions, the particles are transferred to the screening device, where the particles outside the specified range of 4-50 mesh are separated; the final particle size requirements are met The product is bulk packed in 10 kg bags.

Embodiment 2

[0022] Take benzoate 6%, abamectin 3%, emamectin benzoate 1%, sucrose 15%, sodium lauryl sulfate 5%, N-methyl N-oleoyl taurine Sodium 7%, Polysiloxane 3%, Alkylphenol Ethoxylates 0.5%, Acetophenone 0.4%, Silica 0.3% Dry blend active ingredient benzoate in 60 liter portable blender and other raw materials, then add about 15% (weight) of water; then transfer the wet material to a basket extruder equipped with a 1.0 mm sieve; each batch is divided into two small batches, and the inlet temperature is controlled at 60°C The extrudates were dried on a fluidized bed dryer for 13-15 minutes under the condition of an air flow of 1 m / min. And dry in a single drying cycle, no additional stirring is required in the drying cycle; under vacuum conditions, the particles are transferred to the screening device, where the particles outside the specified range of 4-50 mesh are separated; the final particle size requirements are met The product is bulk packed in 10 kg bags.

Embodiment 3

[0024] Take benzoate 6%, abamectin 5%, emamectin benzoate 2%, sucrose 25%, sodium lauryl sulfate 7%, N-methyl N-oleoyl taurine Sodium 8%, polysiloxane 6%, alkylphenol ethoxylate 0.8%, acetophenone 0.7%, bentonite 15%, gum arabic 0.2, penetrant OT 0.3% dry blended in a 60 liter portable blender and active ingredient benzoate and other raw materials, followed by the addition of about 15% (by weight) of water; the wet mass was then transferred to a basket extruder fitted with a 1.0 mm screen; each batch was divided into two small For batches, the extrudates were dried on a fluidized bed drier for 13-15 min at an inlet temperature of 60°C and an air flow of 1 m / min. And dry in a single drying cycle, no additional stirring is required in the drying cycle; under vacuum conditions, the particles are transferred to the screening device, where the particles outside the specified range of 4-50 mesh are separated; the final particle size requirements are met The product is bulk packed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com