Cetirizine hydrochloride tablet

The technology of cetirizine hydrochloride and cetirizine is applied in the directions of pill delivery, organic active ingredients, medical preparations containing active ingredients, etc., and can solve the problems of increased tablet weight, complicated preparation process, inconvenient medication for patients, and the like, Achieve the effect of no corrosion and rapid dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

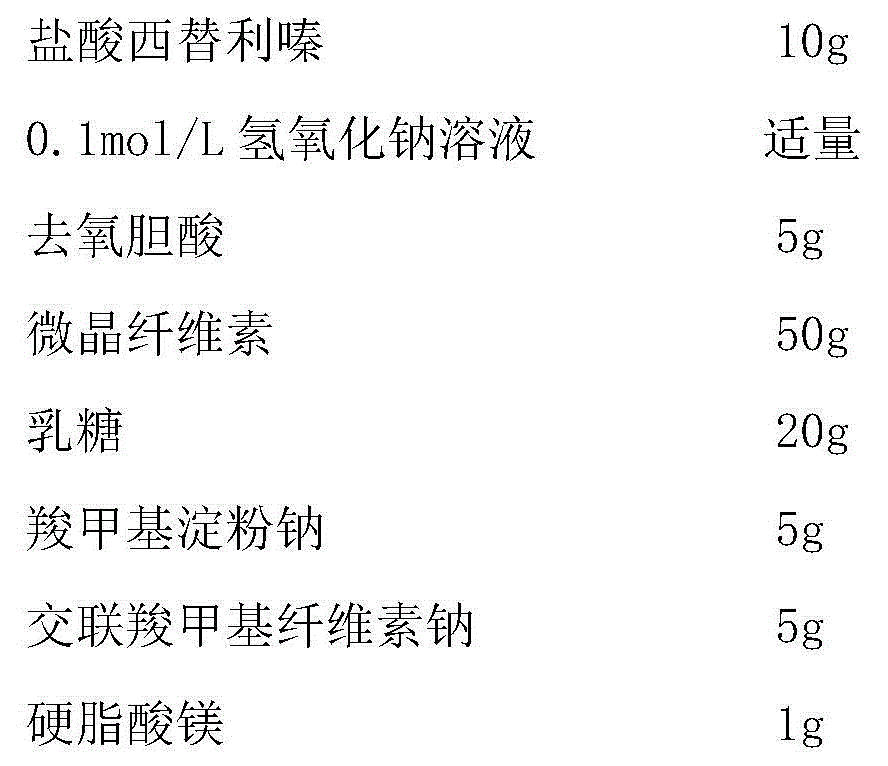

Embodiment 1

[0018]

[0019] Preparation Process:

[0020] Cetirizine hydrochloride is dissolved in 0.1mol / L sodium hydroxide solution aqueous solution, forms cetirizine base, causes its solubility to drop and precipitates out, filters, dries, pulverizes, obtains the powder of cetirizine; Cetirizine Alkali and deoxycholic acid were dissolved in ethanol, and the ethanol was removed by rotary evaporation to obtain cetirizine deoxycholic acid dispersion powder, and then mixed with the prescribed amount of microcrystalline cellulose, lactose, sodium carboxymethyl starch, cross-linked carboxy Sodium methylcellulose and magnesium stearate were uniformly mixed and compressed into tablets to obtain a rapidly dissolving cetirizine tablet.

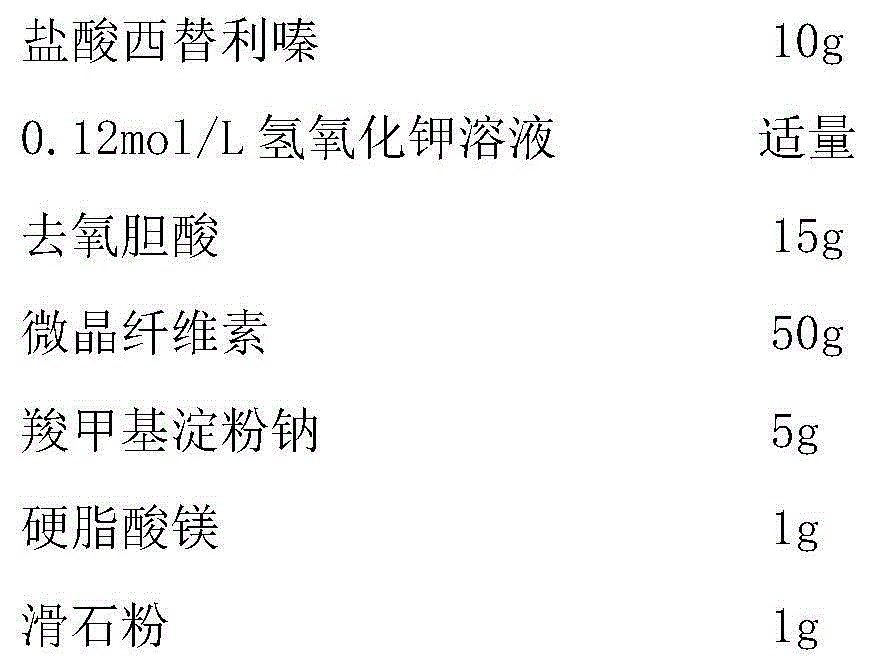

Embodiment 2

[0022]

[0023] Preparation Process:

[0024] Cetirizine hydrochloride is dissolved in 0.1mol / L potassium hydroxide solution aqueous solution to form cetirizine base, causing its solubility to drop and precipitate out, filter, dry and pulverize to obtain the powder of cetirizine; cetirizine Alkali and deoxycholic acid are dissolved in ethanol, and the ethanol is removed by rotary evaporation to obtain cetirizine deoxycholic acid dispersion powder, and then mixed with the prescribed amount of microcrystalline cellulose, sodium carboxymethyl starch, magnesium stearate, The talcum powder was mixed uniformly and tableted to obtain a rapidly dissolving cetirizine tablet.

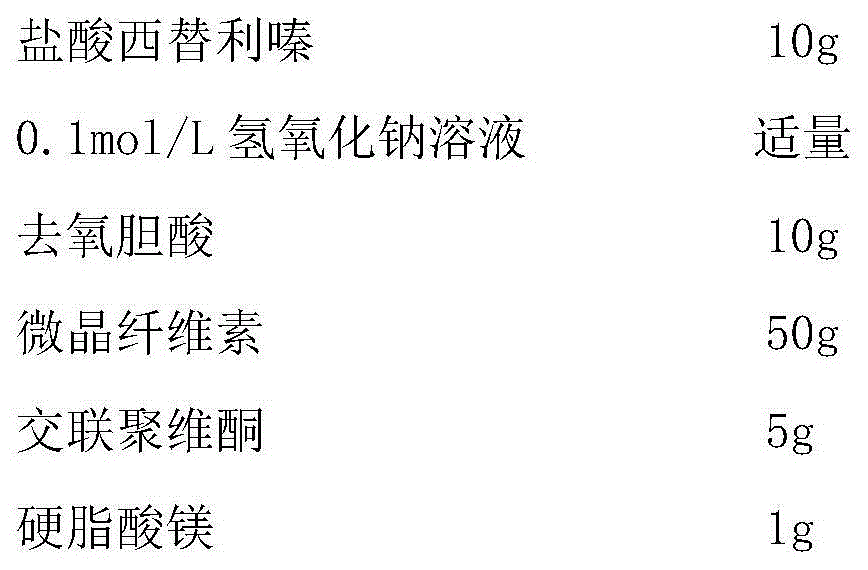

Embodiment 3

[0026]

[0027] Preparation Process:

[0028] Cetirizine hydrochloride is dissolved in 0.1mol / L sodium hydroxide solution aqueous solution, forms cetirizine base, causes its solubility to drop and precipitates out, filters, dries, pulverizes, obtains the powder of cetirizine; Cetirizine Alkali and deoxycholic acid are dissolved in ethanol, and the ethanol is removed by rotary evaporation to obtain cetirizine deoxycholic acid dispersion powder, which is then mixed with the prescribed amount of microcrystalline cellulose, crospovidone, and magnesium stearate Uniform, tabletting, obtained the cetirizine tablet that dissolves rapidly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com