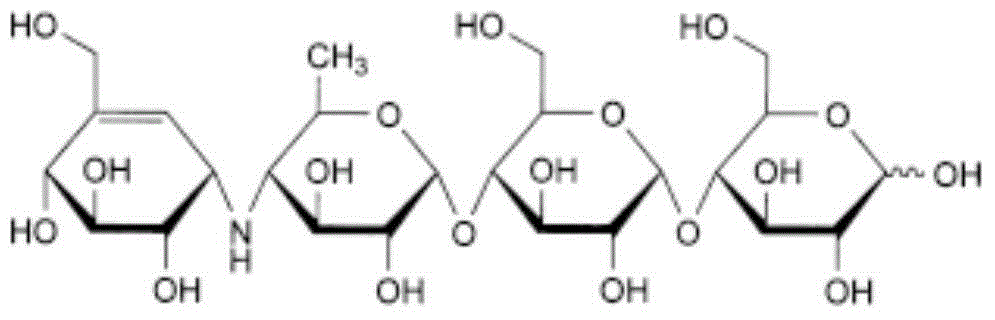

Acarbose capsule and preparation method thereof

A technology of acarbose and capsules, applied in the field of medicine, can solve the problems such as the inability to improve the fluidity, the easy moisture absorption of acarbose, and the powder spraying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] Embodiment 1: Preparation of acarbose capsules

[0095] formula:

[0096] Acarbose

50mg

20mg

90mg

Modified pregelatinized starch

40mg

Sodium octadecyl fumarate

1.5mg

silica

1mg

[0097] Preparation method:

[0098] (1) Make the acarbose that crosses 80 mesh sieves through being pulverized and mix evenly with the lubricant of prescription quantity;

[0099] (2) mix the diluent and the mixed powder obtained in step (1) through pulverizing in advance and passing through an 80-mesh sieve;

[0100] (3) mixing the glidant and the mixed powder obtained in step (2) in a three-dimensional mixer for 5-10 minutes to obtain a uniform total mixture, which is used as a filler for capsules;

[0101] (4) Detect the content of the active substance in the filler, and calculate the loading amount of the filler in each capsule;

[0102] (5) Filling the obtained filler into...

Embodiment 2

[0103] Embodiment 2: preparation of acarbose capsules

[0104] formula:

[0105] Acarbose

50mg

20mg

Cassava starch

87.5mg

Modified pregelatinized starch

40mg

Sodium octadecyl fumarate

1.5mg

silica

1mg

[0106] Preparation method:

[0107] (1) Make the acarbose that crosses 80 mesh sieves through being pulverized and mix evenly with the lubricant of prescription quantity;

[0108] (2) mix the diluent and the mixed powder obtained in step (1) through pulverizing in advance and passing through an 80-mesh sieve;

[0109] (3) mixing the glidant and the mixed powder obtained in step (2) in a three-dimensional mixer for 5-10 minutes to obtain a uniform total mixture, which is used as a filler for capsules;

[0110] (4) Detect the content of the active substance in the filler, and calculate the loading amount of the filler in each capsule;

[0111] (5) Filling the obtained fille...

Embodiment 3

[0112] Embodiment 3: Preparation of acarbose capsules

[0113] formula:

[0114] Acarbose

50mg

15mg

95mg

Modified pregelatinized starch

45mg

Sodium octadecyl fumarate

1.2mg

silica

0.5mg

[0115] Preparation method:

[0116] (1) Make the acarbose that crosses 80 mesh sieves through being pulverized and mix evenly with the lubricant of prescription quantity;

[0117] (2) mix the diluent and the mixed powder obtained in step (1) through pulverizing in advance and passing through an 80-mesh sieve;

[0118] (3) mixing the glidant and the mixed powder obtained in step (2) in a three-dimensional mixer for 5-10 minutes to obtain a uniform total mixture, which is used as a filler for capsules;

[0119] (4) Detect the content of the active substance in the filler, and calculate the loading amount of the filler in each capsule;

[0120] (5) Filling the obtained filler...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com