A kind of chemical looping cycle hydrogen production catalyst and its preparation method and application

A catalyst and chemical chain technology, applied in the field of core-shell composite oxide oxygen carrier catalyst and its preparation, chemical chain cycle hydrogen production catalyst and its preparation, can solve the problem of limited oxygen loading rate, high reaction temperature, unbearable etc. problem, achieve strong oxygen storage capacity, increase oxygen loading rate and activity, and improve selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

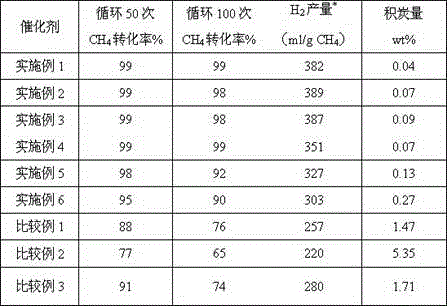

Examples

Embodiment 1

[0021] Carrier preparation: first, monodisperse microporous silica microspheres were prepared by sol-gel method, using ethyl orthosilicate, absolute ethanol and distilled water as raw materials, and acid as catalyst to obtain silica sol, which was Put it in a 120°C oven for gelation, and slowly dry it for 2 weeks to obtain a xerogel; then heat-treat the xerogel at a temperature of 650°C to obtain a silica mesoporous microspherical solid; the acid used for the catalyst can be hydrochloric acid , nitric acid; the molar ratio of acid to silicon is 1:2, the molar ratio of tetraethyl orthosilicate to water is 1:10, and the molar ratio of tetraethyl orthosilicate and ethanol is 1:4, and the acid gel method is used simultaneously Prepare a stable zinc oxide sol; ultrasonically disperse the prepared silica microspheres in distilled water to make a suspension, adjust the acidity of the suspension with nitric acid to make its pH equal to that of the prepared zinc oxide sol, and then Add...

Embodiment 2

[0027] Carrier preparation: first, monodisperse microporous silica microspheres were prepared by sol-gel method, using ethyl orthosilicate, absolute ethanol and distilled water as raw materials, and acid as catalyst to obtain silica sol, which was Put it in a 120°C oven for gelation, and slowly dry it for 2 weeks to obtain a xerogel; then heat-treat the xerogel at a temperature of 400°C~750°C to obtain a mesoporous silica microspherical solid; the acid used in the catalyst It can be hydrochloric acid or nitric acid; the molar ratio of acid to silicon is 1:2, the molar ratio of tetraethyl orthosilicate to water is 1:15, and the molar ratio of tetraethyl orthosilicate to ethanol is 1:3. Prepare a stable zinc oxide sol by degelation method; ultrasonically disperse the prepared silica microspheres in distilled water to make a suspension, and adjust the acidity of the suspension with nitric acid to make its pH value equal to that of the prepared zinc oxide sol equal, then add the p...

Embodiment 3

[0033] Carrier preparation: first, monodisperse microporous silica microspheres were prepared by sol-gel method, using ethyl orthosilicate, absolute ethanol and distilled water as raw materials, and acid as catalyst to obtain silica sol, which was Put it in a 120°C oven for gelation, and slowly dry it for 3 weeks to obtain a xerogel; then heat-treat the xerogel at a temperature of 400°C~750°C to obtain a mesoporous silica microspherical solid; the acid used in the catalyst It can be hydrochloric acid or nitric acid; the molar ratio of acid to silicon is 1:2, the molar ratio of tetraethyl orthosilicate to water is 1:12, and the molar ratio of tetraethyl orthosilicate to ethanol is 1:5. Prepare a stable zinc oxide sol by degelation method; ultrasonically disperse the prepared silica microspheres in distilled water to make a suspension, and adjust the acidity of the suspension with nitric acid to make its pH value equal to that of the prepared zinc oxide sol equal, then add the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com